RQG6133L Automatic Glass Cutting Line

The RQG6133L automatic glass cutting line makes use of the double side glass loading machine to automatically deliver glass panels to the CNC glass cutting machine one by one, and then these glass panels will be cut on the basis of input data. Finally, they are transported to the glass breaking machine to be processed into desired shape.

Advantages

1. This automatic glass cutting line is able to provide safe and effective cutting service without any special requirements for workers.

2. The automatic oil injection and automatic cutting pressure adjustment ensure that desired cutting stability and result will be delivered to customers.

Moreover, the advanced Italian cutting technology and optimized cutting plan make full use of the glass, greatly cutting down the production cost.

3. Owing to the high cutting accuracy and superb stability, this product satisfies all the requirements of customers.

Part 1: Glass Loading Machine

Technical Parameters

| Glass loading machine | RQG6133L |

| Max. glass size (mm) | 6100×3300 |

| Glass thickness (mm) | 2-25 |

| Loading cycle (s) | 40-70 (adjustable) |

| Loading weight (kg) | 1500 |

| Machine height (mm) | 850-950 |

| Transfer speed (m/min) | 0-45 |

| Loading depth (mm) | 750 |

| Machine power | 380V / 50Hz / 12kW |

Detailed Information

1. Osculum and trolley: Imported material

2. PLC: Mitsubishi

3. Electrical system: Omron

4. Pneumatic system: SMC

5. Photoelectric switch: SICK, Germany

6. Brake motor: ChengBang, Taiwan

7. Transducer: Omron

8. This single arm single position glass loading machine takes advantage of the idler wheel to automatically load and transfer glass panels to the right positions, and auto zero position setting is achieved.

9. The roller bar rises and falls as a result of the steady drive, and the LCD touch screen realizes easy control.

10. Our product contains two control modes, automatic control and manual control.

11. Alarm settings are realized.

12. The loading overturn angle can be adjusted with a certain range to best fit for practical applications.

13. This machine offers smooth running, and it is applicable for large panes whose thickness is 3mm.

Part 2: CNC Glass Cutting Machine

Technical Parameters

| Glass cutting machine | RQG6133L |

| Max. glass sheet size (mm) | 6100×3300 |

| Overall dimensions (mm) | 7600×3800 |

| Installed power | 380V / 50Hz / 10.2kW |

| Weight (kg) | 4300 |

| Worktable height (mm) | 900±30 |

| Glass thickness (mm) | 2-25 |

| Cutting speed (m/min) | 0-150 |

| Cutting accuracy (mm) | ±0.3 |

| Optimization mode | OPTIMA |

| Transmission method | Belts |

| Trans speed (m/min) | ≥40 |

| Cutter speed (m/min) | ≥160 |

| Compressed air (Pa) | 0.6 |

| Diagonal line (mm/m) | ≤±0.25 |

| Floor area (m2) | 28 |

1. Other Specification

a. Driving system: X-Y-Z axes controlled by the servo motor which is made in Japan

b. Cutting wheel: It can rotate for 360 degrees to cut the glass into any shape.

c. Oil supply: Automatic oil injection

d. Conveying system: Air cushion (floating)

e. Positioning system: Pneumatic and photoelectric scanning

f. Operator number: One

2. Mechanical Parts

a. Top plate of table: High-standard fireproof and water resistant board

b. Irregularity: <0.20mm/m

c. Rack/Rail: KHK, Japan

d. Time belt: Bredbury, Italy

f. Pneumatic components: SMC, Japan

g. Cutting wheel: Bohle, Germany

h. Table board: Black felt made in Korea

i. Wheel support: Pneumatic and spring conbined

j. Delivery equipment: Automatic induction

3. Electrical Parts

a. HMI: Industrial PC

b. Operation system: Microsoft Windows

c. Power supply: 380V / 50Hz, and a stabilizer is supplied.

d. Motor: Yaskawa servo motor from Japan, control card supplied by Teseo, Italy

e. Transducer: Japan

4. Software

a. The cutting software and optimization software are imported, and the cutting optimization software is provided by OPTIMA, Italy, with original package. Thus, perfect cutting performance is delivered.

b. The automatic calibration function ensures cutting accuracy.

c. The automatic path selection function guarantees best cutting speed.

d. The automatic start point setting and searching functions facilitate the working process.

e. The shape scanner and automatic thickness detector are both applied.

f. This glass cutting machine uses a mouse and a keyboard to input data, and the interface is in English.

Part 3: Fully Automatic Air-Cushion Glass Breaking Machine

Technical Parameters

| Glass breaking machine | RQG6133L |

| Max. glass sheet size (mm) | 6100×3300 |

| Overall dimensions (mm) | 6500×3500×1100 |

| Breaking pole | shape like “ 十 ”, with a gas pump |

| Power (kW) | 9 |

| Table-board | Black felt made in Korea |

| Table top plate | High-standard fireproof and water resistant board |

| Irregularity (mm/m) | < 0.20 |

Related Names

Flat Glass Cutting Machine | Furniture Glass Cutter | Sheet Glass Production

Links:https://globefindpro.com/products/82524.html

-

RLM393/442 Universal Combination Woodworking Machine

RLM393/442 Universal Combination Woodworking Machine

-

RLM260 Universal Combination Woodworking Machine

RLM260 Universal Combination Woodworking Machine

-

RMZ21S Single Line Boring Machine

RMZ21S Single Line Boring Machine

-

Edge Banding Glue

Edge Banding Glue

-

Mini 3G Wireless Router

Mini 3G Wireless Router

-

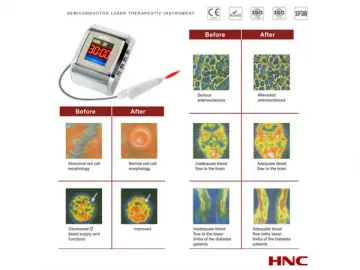

HY30-D Cold Laser Therapy Watch

HY30-D Cold Laser Therapy Watch

-

RX5117B Router

RX5117B Router

-

RBF300C-II Profile Wrapping Machine

RBF300C-II Profile Wrapping Machine

-

RBL2500B Glass Washing Machine

RBL2500B Glass Washing Machine

-

RCQ48C Double-end Cutting Saw

RCQ48C Double-end Cutting Saw

-

RCP260A/310A Veneer Cutting Machine

RCP260A/310A Veneer Cutting Machine

-

RRY4×8/100-3, 120-3 Heated Veneer Press

RRY4×8/100-3, 120-3 Heated Veneer Press