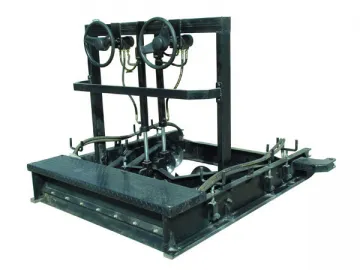

Synchronous Chip Seal Truck

The synchronous chip seal truck distributes bitumen binder and chippings simultaneously so that they can have adequate surface contact to get maximum adhesion.

This synchronous chip sealer is developed independently by our company on the basis of our bitumen distributor and chip spreader, combining merits of similar products in the world. Thus, it shows the advantages of compact structure, good practicability, easy operation, large capacity, high working efficiency and others.

Technical Parameters

| Model | TSF0814 | TSF0610 |

| Chassis | ZZ3317N4267C1 | ZZ3257N4647C1 |

| Bitumen spraying width | 0.3~4.2 m | 0.3~3.8 m |

| Spraying volume | 0.5~2.5 kg/m² | 0.5~2.5 kg/m² |

| Aggregate spraying width | 0.3~4 m | 0.3~3.8 m |

| Bitumen tank capacity | 8000 L | 6000 L |

| Aggregate tank capacity | 14 m3 | 10 m3 |

| Bitumen heating type | Automatic diesel burner | Automatic diesel burner |

| Size | 11610×2496×3860mm | 9838×2496×3840mm |

Features

1. Our synchronous chip seal truck has a powerful stirring device inside the bitumen tank to uniformly blend all the contents, preventing segregation and other problems. This product is especially suitable for crumb rubber modified asphalt.

2. The spraying nozzles adopted by our chip seal spreader are processed with advanced technique and are strictly examined to make sure that all of them provide the same spraying volume.

3. The optimized separation plate strictly limits the distribution space, so, uniform distribution is achieved. Meanwhile, the rotation speed of rotary drum and the open degree of discharge door are controlled by computer to make sure that the distribution amount of chips can be adjusted at any time.

4. Our sealcoat machine is controlled by computer and is very easy to utilize. Users just need to input spray volume, medium density, spraying width and other parameters, and then, the computer will detect travel speed and work out spray volume by analyzing these data. Finally, it will send out signal to precisely control the spray volume with the help of compensated proportional flow control valve of the hydraulic system.

5. For this chip seal truck, all the key components are imported from renowned suppliers to guarantee stable performance.

Introduction to Synchronous Chip Seal

1. Synchronous chip seal helps low-energy asphalt binder penetrate into the micro fractures of road surface, sealing the cracks.

2. It is substantially a soft ultrathin surface layer of bitumen and gravel, which are combined by asphalt membrane with a certain thickness. It is used to enhance the anti-cracking ability, improve water proof property, heal the block cracks, and reduce the chance of joint reflection crack. Thus, the life of road surface can be extended for over 10 years. The result will be even better if high viscosity binders are applied, such as rubber bitumen, polymer modified bitumen, etc.

3. When used in semi-rigid asphalt pavement, chip seal not only has excellent water sealing effect, but can also significantly put off the occurrence of joint reflection crack.

4. The synchronous chip seal technique greatly increases the friction factor of the road to enhance the slip resistance property. Also, the flatness of road surface can get recovered to some extent.

5. By distributing multiple layers of different sized gravels at some sites, rutting, depression and other distresses can be repaired, which is impossible for common maintenance method.

6. When construction fund is seriously inadequate, chip seal can serve as transition road for low grade roads.

7. Synchronous chip sealing shows the advantage of easy and fast construction, and traffic can pass over this road at reduced speed and fixed time even if the construction has not been finished yet.

8. Synchronous chip seal is an economical way for road maintenance and repair considering its high price performance ratio.

Links:https://globefindpro.com/products/84071.html