Rubber Predispersed Masterbatch MBT

| Product name | MBT-70 | MBT-75 | MBT-80 |

| Composition | 70% 2-Mercaptobenzothiazole 30% Ethylene-propylene rubber carrier and surface active dispersing agent | 75% 2-Mercaptobenzothiazole 25% Ethylene-propylene rubber carrier and surface active dispersing agent | 80% 2-Mercaptobenzothiazole 20% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Specification | 20kg/box | 20kg/box | 20kg/box |

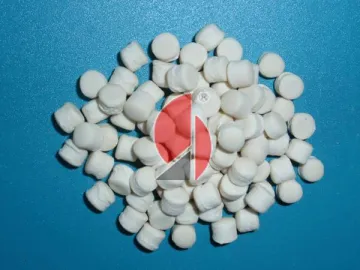

| Appearance | Pale yellow granules | Pale yellow granules | Pale yellow granules |

| Density | 1.20 ± 0.05g/cm3 (25℃) | 1.24 ± 0.05g/cm3 (25℃) | 1.25 ± 0.05g/cm3 (25℃) |

| Mooney viscosity (100℃) | 12±5 | 17±5 | 25±5 |

Technical Feature

The predispersed masterbatch MBT is a quasi-high-speed, multi-function accelerator which has long vulcanization flat period and endows the vulcanized rubber with good physical and mechanical properties. In the vulcanization without sulfur, the pre-dispersed MBT acts as a scorch retarder. It is used as the vulcanization retarder in the CR material. Alkaline accelerators, like aldehyde amines and guanidines, as well as thiurams and dithiocarbamates accelerators have activation effect on the pre-dispersed MBT.

Processing

Powdery MBT is usually easy to fly and adhere to the devices. It is difficult to disperse evenly during mixing. But the pre-dispersed MBT is easy to mix. It will not agglomerate under normal storage conditions. It has good flowability and there is no dust flying. It blends easily into various rubber materials and disperses evenly. This ensures the optimal activity of the effective ingredient. The pre-dispersed MBT is suggested to add in the late stage of mixing.

Application

A variety of industrial products, such as rubber tubes, conveyor belts, driving belts, cable jacket, etc.

Packaging

Calcium plastic box lined with polyethylene bag, 20kg/box

Storage

Stored in a cool, dry place; Sealed storage for 24 months with original packaging

Related Names

Industrial Masterbatch Provider | Natural Rubber Processing | Chemical Ingredient

Links:https://globefindpro.com/products/84061.html

-

Rubber Accelerator MBTS/DM

Rubber Accelerator MBTS/DM

-

Pneumatic Reservoir

Pneumatic Reservoir

-

Street Sweeper

Street Sweeper

-

14

14

-

Radio Controlled Clock / Radio Clock

Radio Controlled Clock / Radio Clock

-

Synchronous Chip Seal Truck

Synchronous Chip Seal Truck

-

Rubber Predispersed Masterbatch DPG

Rubber Predispersed Masterbatch DPG

-

Rubber Accelerator DCBS/DZ

Rubber Accelerator DCBS/DZ

-

Rubber Vulcanizing Agent

Rubber Vulcanizing Agent

-

Rubber Predispersed Masterbatch BZ-80

Rubber Predispersed Masterbatch BZ-80

-

Rubber Accelerator ZDBC/BZ

Rubber Accelerator ZDBC/BZ

-

Rubber Accelerator MBT/M

Rubber Accelerator MBT/M