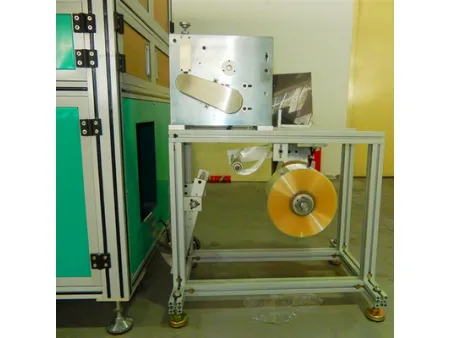

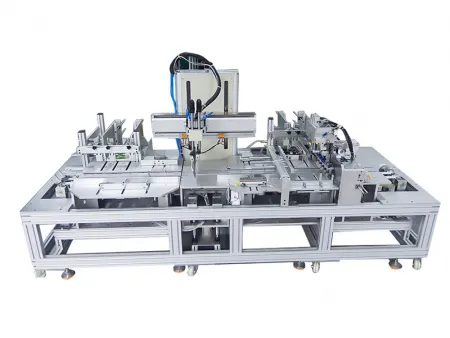

SIM Card Milling Machine, WT-007SCMM

This SIM card milling machine is a smart card processing system that creates cavity where the contact chip will be inserted, comprising of card milling, cavity cleaning, cavity depth measurement and optical character recognition (OCR). This card milling machine is suitable for ISO ID-1 format SIM card production.

Specifications

| Power supply | AC380V/50HZ | Milling accuracy | ±0.02mm |

| Power | 3.5KW | Servo accuracy | X,Y=0.0125mm |

| Air source | 6 kg/cm2 | Control | PLC servo motor |

| Air consumption | 110L/min | Quantity of milling heads | 1/2/4 optional |

| Weight | 900kg | Operators needed | 1 |

| Dimension | 1700x850x1750(mm) | Productivity | Single-chip module card: 6500PCS/H Multi-chip module card: 13000PCS/H |

| Applicable card materials | ISO standard card substrate |

Productivity:

Single-chip module card: 6500PCS/H

Multi-chip module card: 13000PCS/H

Milling accuracy: ±0.02mm

Servo accuracy: X, Y=0.0125mm

Quantity of milling heads: 1/2/4 optional

Applicable card materials: ISO standard card substrate

Operators needed: 1

Power supply: AC380V/50HZ

Power: 3.5KW

Air source: 6 kg/cm 2

Control: PLC servo motor

Air consumption: 110L/min

Dimension: 1700x850x1750(mm)

Weight: 900kg Features Comprising of card milling, vacuum cleaning and cavity depth measurement in one machine; Achieving accurate milling depth, regardless of card thickness and size; Preset standard milling program consists of 4 modules, parameters are programmable according to actual operation needs; Two milling stations (X and Y axes) can work independently or simultaneously to meet specific milling needs; Z axis is driven by high precision servo motor and moves along the guide rail to ensure accurate milling depth; Featuring sampling inspection function, guaranteeing the quality of cards;

Scan QR to Read

Links:https://globefindpro.com/products/8511.html

Links:https://globefindpro.com/products/8511.html

Recommended Products

-

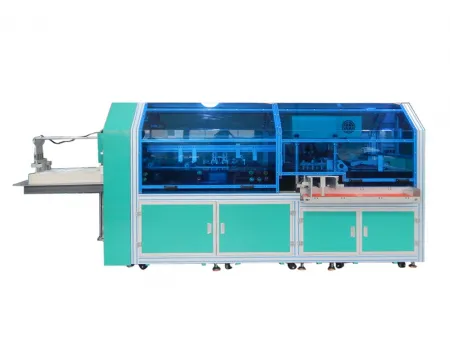

Automated Packaging Machine, Ultrasonic Sealing (30000pcs/Hour), WT-008BZJ

Automated Packaging Machine, Ultrasonic Sealing (30000pcs/Hour), WT-008BZJ

-

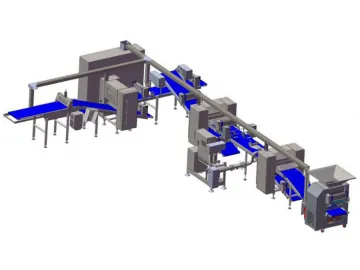

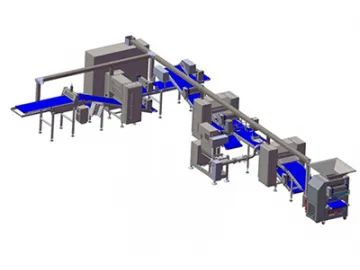

Compact Dough Laminating Line

Compact Dough Laminating Line

-

Twisted Handles Block Bottom Bag Making Machine

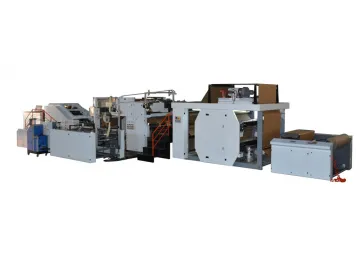

Twisted Handles Block Bottom Bag Making Machine

-

Croissants

Croissants

-

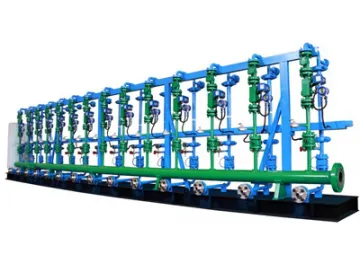

Water Distribution Device for Multi Oil Wells, High Pressure

Water Distribution Device for Multi Oil Wells, High Pressure

-

Swing Check Valve

Swing Check Valve

-

Board Book Mounting and Gluing Machine, WT-007DBJ

Board Book Mounting and Gluing Machine, WT-007DBJ

-

Label Die Cutting Machine, WT-007MQJ

Label Die Cutting Machine, WT-007MQJ

-

16” Electric Balance Bike, KKA-E1

16” Electric Balance Bike, KKA-E1

-

Paper Rope Rewinder

Paper Rope Rewinder

-

Twisted Handles Block Bottom Bag Making Machine with Inline Printing

Twisted Handles Block Bottom Bag Making Machine with Inline Printing

-

Automatic Card Punching Machine (Paper/Plastic Card), WT-010ZDCKJ

Automatic Card Punching Machine (Paper/Plastic Card), WT-010ZDCKJ

Hot Products