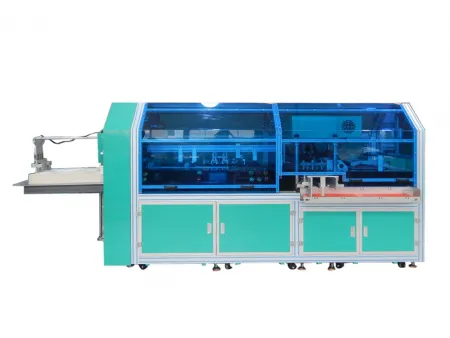

Automatic Card Punching Machine (Paper/Plastic Card), WT-010ZDCKJ

This automatic card punching machine features an automatic sheet feeder coupled with KEYENCE sensor for reliable positioning. Punched cards are created in one step through processes of card forming, corner rounding, hole punching and creasing, and can be automatically collected in an orderly manner. The card punching system is suitable for manufacturing cards of various materials of PVC, ABS, PET, as well as PVC/ABS composite materials with sizes ranging from 54*54mm to 210*210mm.

Finished Products Hang tags

Kid's books

Playing cards

Flashcards

Children's early learning books

Folded leaflets

Specifications

| Power supply | AC 380V/50 HZ | Sheet format | Max. (L*W) 1100*630MM Min. (L*W) 450*450MM |

| Total power | 10KW | Control | PLC control servo system |

| Air source | 6 kg/cm2 | Operators needed | 1 |

| Air consumption | Approx. 80L/min | Dimension | L4450*W1500*H1850MM |

| Punching pressure | 2T-6T | Drive | Servo system |

| Weight | Approx. 1800KG | Punched card size | Max. 210*210MM Min. 54*54MM |

| Punching accuracy | ±0.10mm | Productivity | 25000~55000PCS/H |

| Applicable card materials | Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. |

Productivity: 25000~55000PCS/H

Punched card size: Max. 210*210MM /Min. 54*54MM

Punching accuracy: ±0.10mm

Punching pressure: 2T-6T

Sheet format: Max. (L*W) 1100*630MM/ Min. (L*W) 450*450MM

Dimension: L4450*W1500*H1850MM

Weight: Approx. 1800KG

Operators needed: 1

Power supply: AC 380V/50 HZ

Total power: 10KW

Control: PLC control servo system

Air source: 6 kg/cm2

Air consumption: Approx. 80L/min

Drive: Servo system

Applicable card materials: Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. Features

Vacuum suction feeder

Coupled with vacuum suction cups and stepper motor, the sheet feeder can implement automatic suction and feeding process;

Automatic alignment unit

After the sheets are fed to designated position by motor driven conveying belt, KEYENCE sensor provides automatic alignment and ensures accurate positioning;

Servo punching unit

High torque servo motor is adopted to guarantee stable work pressure and low noise level, the working speed is adjustable;

Inspection unit

The quantity of sheets to feed is guaranteed, alarm will be actuated in the event of abnormal operation;

Punched card collection unit

Specially designed card collecting structure allows punched cards to be automatically collected in an orderly manner, while the cutting scraps are automatically removed, eliminating the need for secondary sorting;

Links:https://globefindpro.com/products/8505.html

-

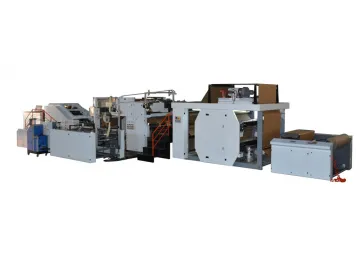

Twisted Handles Block Bottom Bag Making Machine with Inline Printing

Twisted Handles Block Bottom Bag Making Machine with Inline Printing

-

Paper Rope Rewinder

Paper Rope Rewinder

-

16” Electric Balance Bike, KKA-E1

16” Electric Balance Bike, KKA-E1

-

Label Die Cutting Machine, WT-007MQJ

Label Die Cutting Machine, WT-007MQJ

-

Board Book Mounting and Gluing Machine, WT-007DBJ

Board Book Mounting and Gluing Machine, WT-007DBJ

-

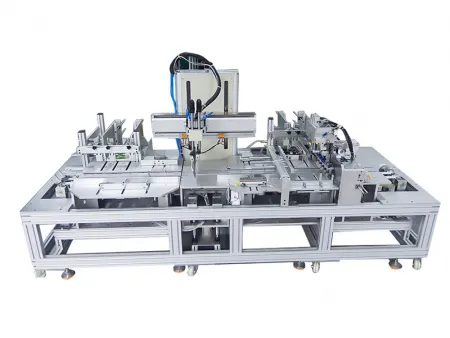

SIM Card Milling Machine, WT-007SCMM

SIM Card Milling Machine, WT-007SCMM

-

Magnetic Tape Laying Machine, WT-007BCT

Magnetic Tape Laying Machine, WT-007BCT

-

Automated Packaging Machine, Heat Sealing (10000pcs/Hour), WT-007BZJ

Automated Packaging Machine, Heat Sealing (10000pcs/Hour), WT-007BZJ

-

Card Punching Machine (Paper/Plastic Card), WT-007CKJ

Card Punching Machine (Paper/Plastic Card), WT-007CKJ

-

Children’s Book Die Cutting Machine, WT-009MQJ

Children’s Book Die Cutting Machine, WT-009MQJ

-

Bag Handle Making Machine

Bag Handle Making Machine

-

Smart Card Chip Implanting Machine, WT-007SCEM

Smart Card Chip Implanting Machine, WT-007SCEM