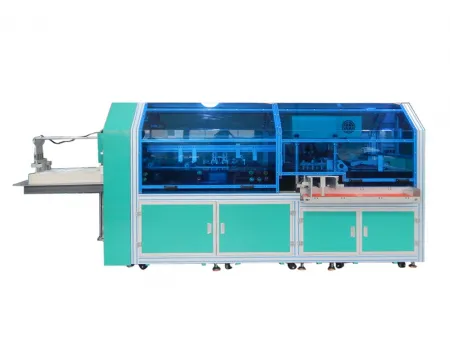

Smart Card Chip Implanting Machine, WT-007SCEM

WT-007SCEM SIM card chip implanting machine is capable of punching various chip modules and then inserting the chip module onto the card cavities. The SIM card machine integrates chip module punching, chip module implanting and ATR testing functions.

Specifications

| Power supply | AC380V/50HZ | Servo accuracy | X, Y=0. 0125mm |

| Total power | 5.0KW | Mechanical accuracy | 0.01mm |

| Air source | 6 kg/cm2 | Control | Single axis located PLC control |

| Air consumption | 120L/min | Applicable card materials | ISO PVC card |

| Weight | 850kg | Operators needed | 1 |

| Dimension | 2100x850x1750(mm) | Productivity | 5500~6500PCS/H |

| Pass rate | 99.9% |

Productivity: 5500~6500PCS/H

Applicable card materials: ISO PVC card

Mechanical accuracy: 0.01mm

Servo accuracy: X, Y=0. 0125mm

Pass rate: 99.9%

Operators needed: 1

Control: Single axis located PLC control

Air consumption: 120L/min

Power supply: AC380V/50HZ

Total power: 5.0KW

Air source: 6 kg/cm2

Weight: 850kg

Dimension: 2100x850x1750(mm) Features Integrating IC module punching, implanting, bonding and testing in one machine; Card position is precisely aligned, ensuring high chip module implanting accuracy; High precision ball screw structure with servo motor provides precise and stable chip module transporting; Utilizing circulating water cooling system to meet the temperature requirements of hot melt adhesive bonding; Chip module testing device provides fast and accurate measurement;

Scan QR to Read

Links:https://globefindpro.com/products/8499.html

Links:https://globefindpro.com/products/8499.html

Recommended Products

-

Bag Handle Making Machine

Bag Handle Making Machine

-

Children’s Book Die Cutting Machine, WT-009MQJ

Children’s Book Die Cutting Machine, WT-009MQJ

-

Card Punching Machine (Paper/Plastic Card), WT-007CKJ

Card Punching Machine (Paper/Plastic Card), WT-007CKJ

-

Automated Packaging Machine, Heat Sealing (10000pcs/Hour), WT-007BZJ

Automated Packaging Machine, Heat Sealing (10000pcs/Hour), WT-007BZJ

-

Magnetic Tape Laying Machine, WT-007BCT

Magnetic Tape Laying Machine, WT-007BCT

-

Automatic Card Punching Machine (Paper/Plastic Card), WT-010ZDCKJ

Automatic Card Punching Machine (Paper/Plastic Card), WT-010ZDCKJ

-

Flexo Printing Machine

Flexo Printing Machine

-

Board Book Die Cutting Machine, WT-008MQJ

Board Book Die Cutting Machine, WT-008MQJ

-

Automatic Smart Card Milling and Implanting Machine, WT-007SCMEM

Automatic Smart Card Milling and Implanting Machine, WT-007SCMEM

-

Upright Flat Handles Block Bottom Paper Bag Making Machine

Upright Flat Handles Block Bottom Paper Bag Making Machine

-

Card Punching Machine (Paper/Plastic Card), WT-009CKJ

Card Punching Machine (Paper/Plastic Card), WT-009CKJ

-

1080P Wireless Security Camera with LED Light, WF794

1080P Wireless Security Camera with LED Light, WF794

Hot Products