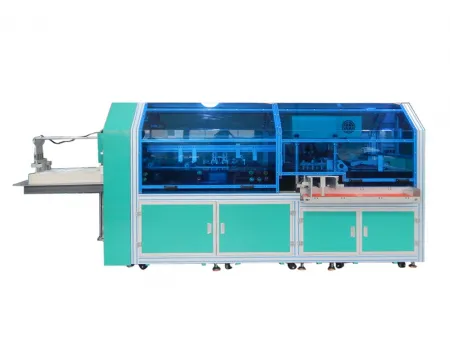

Magnetic Tape Laying Machine, WT-007BCT

Our automatic magnetic tape laying machine is typically designed for laying magnetic strips onto film or card sheet materials. The pressure and heat are used in magnetic tape laying process, the temperature of laying rollers is independently controlled for an optimal laying result.

Specifications

| Power supply | AC 380V/50 HZ | Format | 3X8/4X8/5X5 optional |

| Total power | 2.5KW | Control | PLC control servo system |

| Air source | 6 kg/cm2 | Operators needed | 1 |

| Air consumption | Approx. 80L/min | Dimension | L2250*W1000*H1700MM |

| Laying accuracy | ±0.15mm | Product thickness | 0.2mm~0.8mm |

| Temperature control accuracy | ±2℃ | Temperature control range | 0~400℃ |

| Magnetic tape width | 6.35mm/8.4mm/12.7mm | Quantity of magnetic tapes | 5~8 |

| Applicable materials | Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc. | Productivity | 900 Sheet/H |

Productivity: 900 Sheet/H

Format: 3X8/4X8/5X5 optional

Product thickness: 0.2mm~0.8mm

Magnetic tape width: 6.35mm/8.4mm/12.7mm

Quantity of magnetic tapes: 5~8

Laying accuracy: ±0.15mm

Applicable materials: Paper card, PVC, ABS, PET, PVC/ABS composite materials, etc.

Operators needed: 1

Dimension: L2250*W1000*H1700MM

Power supply: AC 380V/50 HZ

Control: PLC control servo system

Air source: 6 kg/cm2

Air consumption: Approx. 80L/min

Temperature control accuracy: ±2℃

Temperature control range: 0~400℃ Features Servo motor driven roller conveys sheets, offering precise sheet feeding and adjustable feeding speed;

Independent temperature control and PLC control; Multi laying rollers with adjustable pressure ensure optimal laying result; Pressure and temperature of each laying roller are individually controlled; Details Feeding unit

Tracks of magnetic strips

Spot welding unit

Collection unit

Scan QR to Read

Links:https://globefindpro.com/products/8504.html

Links:https://globefindpro.com/products/8504.html

Recommended Products

-

Automatic Card Punching Machine (Paper/Plastic Card), WT-010ZDCKJ

Automatic Card Punching Machine (Paper/Plastic Card), WT-010ZDCKJ

-

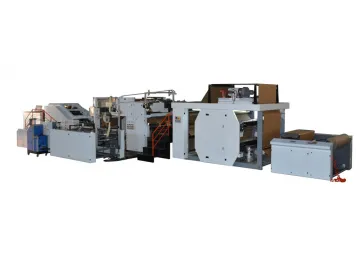

Twisted Handles Block Bottom Bag Making Machine with Inline Printing

Twisted Handles Block Bottom Bag Making Machine with Inline Printing

-

Paper Rope Rewinder

Paper Rope Rewinder

-

16” Electric Balance Bike, KKA-E1

16” Electric Balance Bike, KKA-E1

-

Label Die Cutting Machine, WT-007MQJ

Label Die Cutting Machine, WT-007MQJ

-

Board Book Mounting and Gluing Machine, WT-007DBJ

Board Book Mounting and Gluing Machine, WT-007DBJ

-

Automated Packaging Machine, Heat Sealing (10000pcs/Hour), WT-007BZJ

Automated Packaging Machine, Heat Sealing (10000pcs/Hour), WT-007BZJ

-

Card Punching Machine (Paper/Plastic Card), WT-007CKJ

Card Punching Machine (Paper/Plastic Card), WT-007CKJ

-

Children’s Book Die Cutting Machine, WT-009MQJ

Children’s Book Die Cutting Machine, WT-009MQJ

-

Bag Handle Making Machine

Bag Handle Making Machine

-

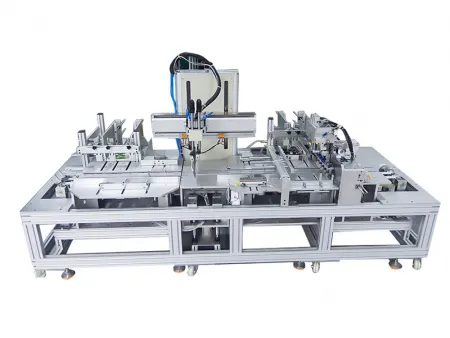

Smart Card Chip Implanting Machine, WT-007SCEM

Smart Card Chip Implanting Machine, WT-007SCEM

-

Flexo Printing Machine

Flexo Printing Machine