Roll Coater

Also called a roller coater, the roll coater is a piece of metal coating equipment used to apply coating to the steel strip surface. It utilizes a roll to carry the coating. As the roll rotates, a layer of wet film with a certain amount of thickness forms around the roll surface. During the rotation, the roll maintains contact with the object to be coated. Via this process, the coating is evenly applied to the surface of the object.

Our roll coater mainly copes with objects with a flat surface. The device is widely used to coat the metal plate, plywood, cloth, and paper, but it is especially suitable for the coating of coil.

Features of the Roll Coater

Everything you get out of coating process is affected by the kind of paint and roll you put into it. The coating thickness and quality directly relates the roll material, configuration, rotating direction, speed ratio, and supply of coating. In terms of driving mode, our roll coater adopts the independent drive manner. Each roll is separately equipped with a drive motor. As with this drive motor, the rotating direction and rotating speed can be changed within their allowable range. Hence, it is safe to say that our roll coating machine is easy to use.

Links:https://globefindpro.com/products/85921.html

-

Drying Oven

Drying Oven

-

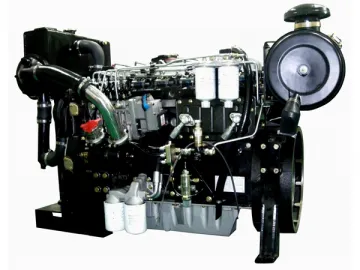

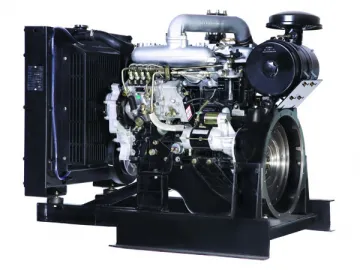

Diesel Engine Accessories

Diesel Engine Accessories

-

Continuous Annealing Furnace

Continuous Annealing Furnace

-

Marine Auxiliary Engine

Marine Auxiliary Engine

-

Electrostatic Oiler

Electrostatic Oiler

-

FOTON® Genset Engine

FOTON® Genset Engine

-

FDM720 Wheel Loader

FDM720 Wheel Loader

-

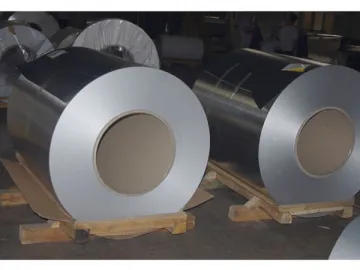

Single Side PE Coated Aluminum Coil

Single Side PE Coated Aluminum Coil

-

Stucco Embossed Aluminum Coil

Stucco Embossed Aluminum Coil

-

Diamond Embossed Aluminum Coil

Diamond Embossed Aluminum Coil

-

Stone Coated Metal Roof Tiles (Roof Shingle)

Stone Coated Metal Roof Tiles (Roof Shingle)

-

1100 Mill Finish Aluminum Coil

1100 Mill Finish Aluminum Coil