Drying Oven

As an indispensable piece of drying equipment on the color coating line, galvanizing line, and pickling line, the drying oven is mainly used to dry and solidify the coating, and remove the liquid part from the strip steel surface.

The industrial drying oven is comprised of oven body, internal ducting, cross-flow oven, air circulation fan, and external ducting. It promotes drying by efficient application of air re-circulated heat. Hot air is repeatedly sent into the oven body in order that the oven can maintain a relatively constant temperature.

As the steel strip passes through the drying oven, the coating on the strip surface dries and cures. The curing oven can be divided into different sections, each for a specific processing. Temperature in each section is separately controlled so that it only fluctuates within a tight range. The heating energy sources could be natural gas, electricity, steam, or oil dependant on the actual circumstances.

Oven Body for the Drying Oven

In the oven body, temperature is maintained at a relatively constant level. As the steel strip passes the oven, it will receive passivation and squeezing to remove the water left on the surface.

Internal Ducting System for the Drying Oven

The function of internal ducting is to spray the hot air over the strip steel and let the liquid part of the coating evaporate.

Electrical Heater for the Drying Oven

Convert the electrical energy to heat energy.

Links:https://globefindpro.com/products/85922.html

-

Diesel Engine Accessories

Diesel Engine Accessories

-

Continuous Annealing Furnace

Continuous Annealing Furnace

-

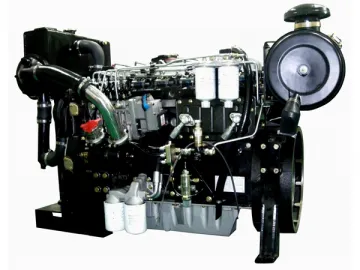

Marine Auxiliary Engine

Marine Auxiliary Engine

-

Electrostatic Oiler

Electrostatic Oiler

-

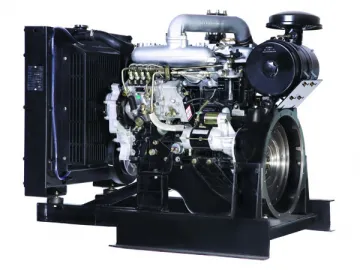

FOTON® Genset Engine

FOTON® Genset Engine

-

Tractor Engine

Tractor Engine

-

Roll Coater

Roll Coater

-

FDM720 Wheel Loader

FDM720 Wheel Loader

-

Single Side PE Coated Aluminum Coil

Single Side PE Coated Aluminum Coil

-

Stucco Embossed Aluminum Coil

Stucco Embossed Aluminum Coil

-

Diamond Embossed Aluminum Coil

Diamond Embossed Aluminum Coil

-

Stone Coated Metal Roof Tiles (Roof Shingle)

Stone Coated Metal Roof Tiles (Roof Shingle)