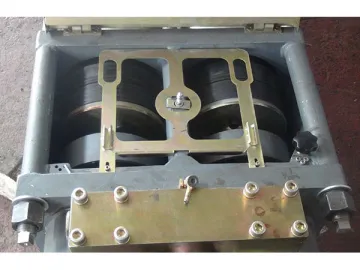

Concrete Pump Hopper

The concrete pump hopper provides a temporary storage space for concrete. It ensures there is always enough concrete ready to be pumped, thus enabling a continuous, uninterrupted pumping operation. Within the hopper, two activities take place: concrete mixing and transferring. Concrete particles are evenly mixed by the mixing vanes. Then the properly-mixed concrete is drawn into the pumping cylinder from the hopper before being pumped out to the discharge conduit via the S-tube valve. The power for concrete drawing and pumping motion is given by the hydraulic cylinder.

Features

1. The pilot hole in the concrete pump hopper is drilled by using the NC boring machine. The machine enables good linearity and high dimensional accuracy of the hole.

2. Previous hopper tank was an assembly of 7 separate stamped parts welded together. Now it is reduced to 3 separate one-piece stampings that have been welded together. Fewer parts means less welding defects, such as undercut, holes, and pores, where concrete materials are easily trapped and subsequently build up on the surface. It also reduces the risk of hopper outlet blockage.

3. We can customize the hopper according to the dimensions specified on your drawings.

Related Names

Concrete Placing Bucket | Premixed Concrete Hopper | Concrete Mixture Container

Links:https://globefindpro.com/products/86149.html

-

Motorcycle Rear Brake Master Cylinder

Motorcycle Rear Brake Master Cylinder

-

Digital LCD Motorcycle Speedometer

Digital LCD Motorcycle Speedometer

-

Motorcycle Brake Caliper

Motorcycle Brake Caliper

-

Concrete Pump Water Tank

Concrete Pump Water Tank

-

Motorcycle Brake Disk

Motorcycle Brake Disk

-

Concrete Pump Delivery Cylinder

Concrete Pump Delivery Cylinder

-

Motorcycle Fanfare Horn

Motorcycle Fanfare Horn

-

NRJ618SL HD LED Array IR Dome IP Camera

NRJ618SL HD LED Array IR Dome IP Camera

-

NRQ618SL HD LED Array IR Dome IP Camera

NRQ618SL HD LED Array IR Dome IP Camera

-

Concrete Pump S-Tube Valve

Concrete Pump S-Tube Valve

-

13m DD6137K03 Tour Bus

13m DD6137K03 Tour Bus

-

Plutus Right Hand Drive Double Cab Pickup Truck

Plutus Right Hand Drive Double Cab Pickup Truck