Steel Concrete Pump Wear Plate, Steel Concrete Pump Cutting Ring

The wear plate for concrete pump is a critical component in the concrete pumping system. It resembles a spectacle frame, and thus is often referred to as the spectacle plate.

The wear plate is installed on the rear wall of the concrete hopper. It has two openings. Each opening is connected to the outlet end of the concrete pumping cylinder. During pumping operation, the plate can serve as a seal for the hopper while offering protection against wear at the same time.

The cutting ring, or wear ring, is mounted in the opening of the S-tube valve assembly. It protects the inlet end of the S-tube valve against wear.

The wear ring is often pressed against the wear plate. Its opening should be in alignment with one of the two openings of the plate. This allows the concrete coming from the outlet end of pumping cylinder to pass through the S-tube valve while a tight seal between the ring and plate can be formed. The ring can be swung away from the spectacle plate under the action of a crank arm. During this movement, a large shearing force is produced and acts upon the concrete aggregate to cut off its supply.

Features

1. Tungsten steel is a kind of wear-resistant material independently developed by our company. It consists of two pieces of metals, steel and tungsten carbide, which has been joined together through special welding process. Using tungsten steel instead of tungsten carbide as the welding electrodes in the process of bead welding eliminates pores that might lead to the breakage of the plate and ring. Tungsten steel added in the making of joint means doubled use life of the spectacle plate and cutting ring.

2. Special technologies are used to enable a fast removal of piston in the cylinder and a free switch between high and low pumping pressure. They also make pump maintenance easier, faster than before. This comes with financial benefits, since repair work takes up less labor cost. Centralized and automatic lubrication technology, forced heat dissipation technology, and flexible flow direction reversal technology reduces the power consumption of the diesel engine, extends the use life of the concrete pump and enables a reduced operating cost.

3. Our spectacle wear plate and wear ring are widely applicable in the concrete machinery. They are compact, mechanically strong, and resistant to impact and wear. They can bond very tightly to each other, and thus are suitable for use in demanding pumping applications to allow large amount of concrete to pass at one time.

4. Custom options are also available.

| Packed Wear Plate | Wear Plate and Wear Ring Storage |

Related Names

Abrasion Resistant Metals | Tungsten Cut Off Rings | Concrete Equipment Supplies

Links:https://globefindpro.com/products/86161.html

-

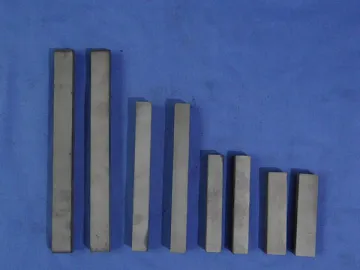

Tungsten Steel Strip

Tungsten Steel Strip

-

Motorcycle Siren Horn

Motorcycle Siren Horn

-

Motorcycle Handlebar Switch

Motorcycle Handlebar Switch

-

Motorcycle Polyphonic Horn

Motorcycle Polyphonic Horn

-

Motorcycle Clothing

Motorcycle Clothing

-

Motorcycle Handlebar Lever

Motorcycle Handlebar Lever

-

Concrete Pump Main Cylinder

Concrete Pump Main Cylinder

-

NRC763G HD LED Array IR IP Camera

NRC763G HD LED Array IR IP Camera

-

Tricycle

Tricycle

-

Motorcycle Front Brake Master Cylinder

Motorcycle Front Brake Master Cylinder

-

Concrete Pump Delivery Cylinder

Concrete Pump Delivery Cylinder

-

Motorcycle Brake Disk

Motorcycle Brake Disk