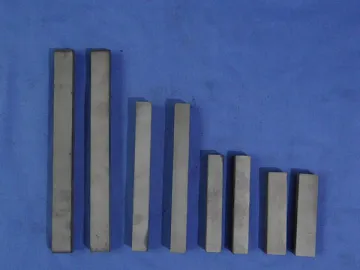

Tungsten Steel Strip

The phrase “wear-resistant” makes sense that in a vertical shaft impactor our tungsten steel strip is used to make the rotor tip (or the tip plate of the rotor as someone might call it). Given the high-speed impact involved in the rock breaking process, the rotor tip must be hard enough to withstand the impact caused by collision, while at the same time it should have enhanced abrasion-resistance. According to the kind of rocks to be destructed, users should choose a suitable type of tungsten steel to make the rotor tip. On average, the use life of each piece of tungsten steel is between 40 and 70 hours.

Based on the fact that the impact force caused by rock collision often acts on one centralized point of the rotor tip during rock breaking, we have designed the bridge-type irregular-shaped tungsten steel strip, which is specially intended for cobble stone breaking applications. Its novel shape design not only improves the use life of the tungsten steel, but also reduces cost that customers would otherwise spend on rotor tip repair and replacement.

Advantages

1. The advanced near-net shape forming technique is utilized to process the tungsten steel into various complex shapes with little effort. It saves processing cost. The product also can be made according to the dimensions specified on your technical drawing.

2. Each irregular-shaped product offers choices of various specifications. We have designed a wide range of tools, and have advanced shape-forming equipment and techniques. Those are necessary to make a suitable irregular-shaped tungsten steel strip to solve your specific application.

3. We also keep enough semi-finished tungsten steel strip in stock. Via our first-rate machining equipment, the workpiece can be processed into different shapes to suit for specific applications.

Parameters

Rockwell Hardness: HRA≥87

Bending Strength: T.R.S≥2300N/mm2

Related Names

Tungsten Carbide Bar | Cemented Carbide Bar | Metal Supply

Links:https://globefindpro.com/products/86163.html

-

Motorcycle Siren Horn

Motorcycle Siren Horn

-

Motorcycle Handlebar Switch

Motorcycle Handlebar Switch

-

Motorcycle Polyphonic Horn

Motorcycle Polyphonic Horn

-

Motorcycle Clothing

Motorcycle Clothing

-

Motorcycle Handlebar Lever

Motorcycle Handlebar Lever

-

Motorcycle Lock Set

Motorcycle Lock Set

-

Steel Concrete Pump Wear Plate, Steel Concrete Pump Cutting Ring

Steel Concrete Pump Wear Plate, Steel Concrete Pump Cutting Ring

-

Concrete Pump Main Cylinder

Concrete Pump Main Cylinder

-

NRC763G HD LED Array IR IP Camera

NRC763G HD LED Array IR IP Camera

-

Tricycle

Tricycle

-

Motorcycle Front Brake Master Cylinder

Motorcycle Front Brake Master Cylinder

-

Concrete Pump Delivery Cylinder

Concrete Pump Delivery Cylinder