Seamless Alloy-Steel Pipes

The seamless alloy-steel pipe derives its name from the raw material that is used to make the pipe. It can be used as a structural member or for high-pressure and high-temperature applications. What differs from the alloy steel machining process is that the pipe should go through the annealing process to have its mechanical properties altered to meet the related requirements.

The seamless alloy-steel pipe contains higher chromium content than plain-carbon steel pipes. Increased chromium content in the pipe means enhanced ability to resist high temperature, low temperature, and corrosion. Due to the good ductility, our alloy-steel tubular product can have widespread applications in the petroleum, aerospace, chemical engineering, electricity, boiler, and military industries.

Two forms of seamless alloy-steel pipes are available in our company: hot-rolled and cold-drawn. Cold-drawn pipes can be broadly grouped into two types: round- and irregularly-shaped.

One of the most pleasing features of our alloy-steel tubular product is that it can be totally reclaimed in good condition. The recycling action is in line with the national strategy on energy efficiency and environmental protection. Hence, the country is gearing another boost in the alloy-steel pipe applications in new fields, such as electricity plant, nuclear power plant, high-pressure boiler, and high-temperature super-heater and re-heater.

This series of seamless pipe allows for bending, flanging, and other similar forming operations like fusion welding. The alloy steel used to make the pipe has been chemically and mechanically tested for the tensile property and hardness. Each pipe also go through hydrostatic testing and non-destructive testing to see whether it is fit for the intended purpose.

Please note

Customer ordered products will be put into a crate. On both ends of the crate are listed the order number, heat number, dimensions, weight, and bundles. The products also can be packed as per customer's requirements.

Material: 16-50Mn, 27SiMn, 40Cr, 12-42CrMo, A333, 12Cr1MoVG, A335P91(T91),15CrMoG,20G, Cr9Mo(P9), 15CrMo(P11,P12), 10CrMo910(P22/T22), Cr5Mo(P5), Cr9Mo(P9)

Package

Loose Package/Bundles/Wooden Case, or as per customer's requirements.

Test and Inspection

Chemical Property Check, Mechanical Property Check (hardness, impact, tensile strength, yield strength, percentage elongation, flaring test, flattening test, bending test ), surface and dimensional inspection, non-destructive testing, hydrostatic testing.

Surface Treatment

Oil immersion, gloss oil coating, passivation, phosphating, sand blasting

Heat Treatment

Annealing/Normalizing Tempering

Normalizing Tempering/Quenching Tempering

Normalizing-Tempering

Required Mechanical Testing

Horizontal or longitudinal tension test, flattening test, hardness test, bending test

As a technology-based manufacturer, Borun Company strives to offer high quality products to customers. We live by morals of integrity and honest and are keenly interested in cooperation with customers in an attempt to achieve double winning.

Related Names

High Temperature Piping | Thick Wall Tube | Corrosion Resistant Pipe

Links:https://globefindpro.com/products/86337.html

-

Komatsu Excavator Cab Door

Komatsu Excavator Cab Door

-

Komatsu Bulldozer Idler

Komatsu Bulldozer Idler

-

Komatsu Bulldozer Ripper

Komatsu Bulldozer Ripper

-

Komatsu Excavator Track Chain and Track Shoe

Komatsu Excavator Track Chain and Track Shoe

-

Casing Pipe

Casing Pipe

-

Komatsu Bulldozer Sprocket

Komatsu Bulldozer Sprocket

-

Aloe Polysaccharide Essence

Aloe Polysaccharide Essence

-

Anti-Aging Astaxanthin Essence

Anti-Aging Astaxanthin Essence

-

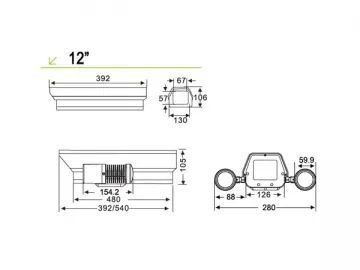

IRH160G-IP IP Camera IR Illuminator Housing

IRH160G-IP IP Camera IR Illuminator Housing

-

Slag Dart Tail

Slag Dart Tail

-

Shantui Bulldozer Sprocket

Shantui Bulldozer Sprocket

-

Komatsu Excavator Counter Weight

Komatsu Excavator Counter Weight