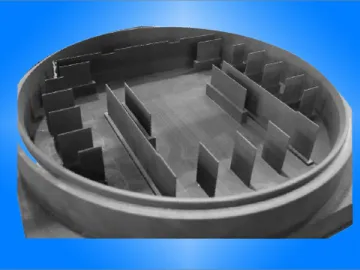

EDM Carbon Graphite Electrode for Electrical Discharge Machining

EDM Carbon Graphite Electrode for Electrical Discharge Machining

As a widely used technology in the mould processing field, EDM always plays an important role. In order to ensure the quality of the mould, the selection of the electrode is critical. As energy conservation and high efficiency become hot topics in the manufacturing industry, more and more customers start selecting the graphite to replace the traditional copper for electrical discharge machining. It has been proved that graphite electrode has some outstanding characteristics that are not possessed by the copper electrode. Adopting graphite electrodes can improve production efficiency, reduce cost and increase profit, thus improving the market competitiveness of the products and enterprises.

We can produce various moulds according to customers' requirements. The finished electrodes meeting the requirements of customers' fixture systems can also be provided. Our EDM electrode mould has high cutting speed and good performance.

Features

1. The graphite electrode has light weight, which can reduce the load of EDM.

2. The product has a high discharge machining speed which is 1.5 to 3 times of that of copper.

3. The graphite electrode has a high density and a low wear rate.

4. With a low thermal expansion rate, deformation of the product caused by heating is reduced.

5. We provide a large number of different graphite electrodes which are suitable for rough machining and finish machining.

Related Names

Electric Discharge Machining used Graphite Product | Graphite Fitting for Electric Spark Machining | Electric Spark Working used Graphite Component | Graphite Parts for Spark Working

<!--[if !supportLineBreakNewLine]-->

<!--[endif]-->

Links:https://globefindpro.com/products/86850.html

-

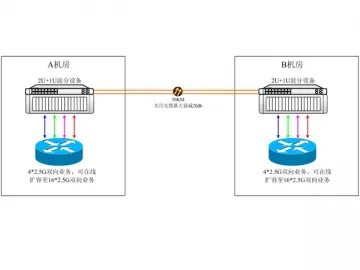

CWDM Point-to-Point Solution

CWDM Point-to-Point Solution

-

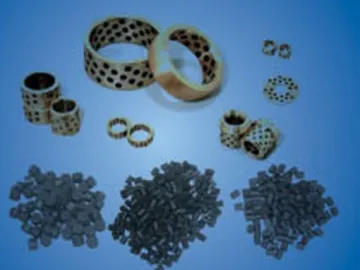

Carbon Graphite Products for Mechanical Engineering Industry

Carbon Graphite Products for Mechanical Engineering Industry

-

Carbon Graphite Products for Aviation and Aerospace Industry

Carbon Graphite Products for Aviation and Aerospace Industry

-

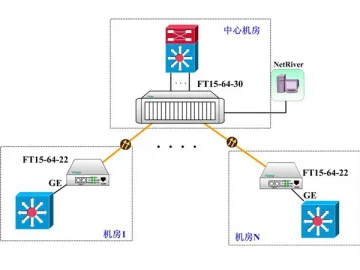

2U Rack Mount CWDM Transmission Equipment

2U Rack Mount CWDM Transmission Equipment

-

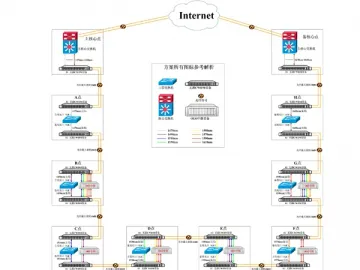

CWDM Ring Network Solution

CWDM Ring Network Solution

-

Ali3202 DVB-C Home Cable TV Set Top Box

Ali3202 DVB-C Home Cable TV Set Top Box

-

10/100/1000M Ethernet Optical Transceiver

10/100/1000M Ethernet Optical Transceiver

-

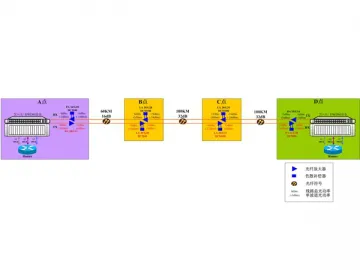

DWDM Long Haul Transmission Solution

DWDM Long Haul Transmission Solution

-

Rack Mount Optical Amplifier (EDFA)

Rack Mount Optical Amplifier (EDFA)

-

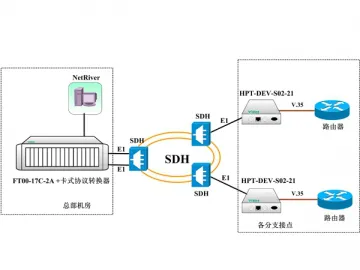

4E1-10/100 Protocol Converter

4E1-10/100 Protocol Converter

-

OLP Optical Line Protection Module

OLP Optical Line Protection Module

-

Concrete Pump Truck

Concrete Pump Truck