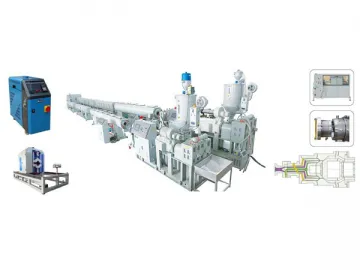

PP-R/FRP/PP-R Three Layer Pipe Extrusion Line

PP-R/FRP/PP-R Three Layer Pipe Extrusion Line

Fiberglass Composite Layer

PP-R Outer Layer

PP-R Inner Layer

PP-R/FRP/PP-R three layer pipe extrusion line can produce the pipe with different materials. Both inner and outer layers are PP-R granular material, and the middle layer is the granule composed of PP-R and glass fiber. Owing to the multi layers of optimized spiral shunt mold, the pipe can provide uniform thickness and no shunt mark. Also, it features high pressure resistance, significant raw material saving, as well as low coefficient of thermal expansion.

Main Specifications

Model | Pipe Diameter Range (mm) | Extruder Model | Mark-line Extruder | ExtrusionSpeed (m/min) | Max. Output (kg/h) | Total Installed Power | Dimension L×W×H |

FPPR/FRP-63 | 20-63 | FSJ-50X33 FSJ-50X33 | FSJ-25X25 | 0.5-15 | 200 | 130 | 30×3.6×2.5 |

FPPR/FRP-110 | 20-110 | FSJ-50X33 FSJ-50X33 | FSJ-25X25 | 0.5-20 | 220 | 150 | 36×3.6×2.5 |

FPPR/FRP-160 | 75-160 | FSJ-65X33 FSJ-65X33 | FSJ-25X25 | 0.5-5 | 360 | 180 | 36×3.6×2.5 |

This three layer pipe extrusion line includes three extruders. The former two machines are used to squeeze out the inner and outer layers. The last machine serves to extrude the glass fiber from middle layer. Controlled by PLC, it can possess easy operation, simple control, fast operating speed, as well as great manpower and time saving. Inside this equipment, the electromagnetic heater helps reduce the electric power by 40% to 60%, which shows remarkable economic benefit. Furthermore, both feeding trough structure and cooling system are unique in their design, and they can increase the output by 15 to 20%. To ensure the superior quality, its electrical components come from numerous world famous brands like Siemens, Schneider, and Omron etc. Also, our product has been approved by CE and ISO quality certification.

Related Names

Multi-Layer Pipe Production Equipment | PPR Pipe Extrusion Machine

Links:https://globefindpro.com/products/87189.html

-

Stained Glass UV Flatbed Printer

Stained Glass UV Flatbed Printer

-

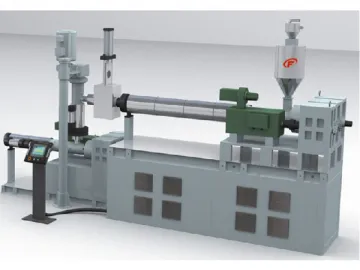

Three Stage Venting and Filtering Plastic Extruder

Three Stage Venting and Filtering Plastic Extruder

-

UV Curable Ink

UV Curable Ink

-

PVC Double and Four Pipe Extrusion Line

PVC Double and Four Pipe Extrusion Line

-

T Series Solvent Ink

T Series Solvent Ink

-

GJ Series Solvent Ink

GJ Series Solvent Ink

-

CJ Series Solvent Ink

CJ Series Solvent Ink

-

UV1209S UV Curable Flatbed Printer

UV1209S UV Curable Flatbed Printer

-

High Efficiency PVC Conical Twin Screw Extruder

High Efficiency PVC Conical Twin Screw Extruder

-

HDPE Large Diameter Hollow Wall Coil Pipe Making Machine

HDPE Large Diameter Hollow Wall Coil Pipe Making Machine

-

PJ Series Solvent Ink

PJ Series Solvent Ink

-

PVC Coal Mining Pipe Production Line (Anti-Static Three Layer Pipe)

PVC Coal Mining Pipe Production Line (Anti-Static Three Layer Pipe)