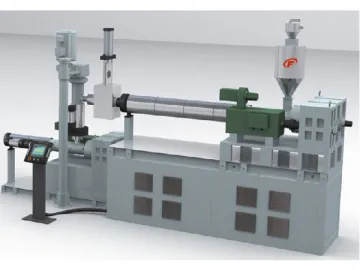

Three Stage Venting and Filtering Plastic Extruder

Three Stage Venting and Filtering Plastic Extruder

Three stage venting and filtering plastic extruder is our self developed patented product. Its electromagnetic heating system can help reduce the electric power by 40% to 50%. Moreover, our product can provide twice more extrusion output than the traditional equipment.

Our three stage venting and filtering plastic extruder is composed of three highly efficient extruders that are connected continuously and run simultaneously. Thanks to the PLC control and the automatic feed system, the operation can be extremely convenient. All the electric parts of our product, such as breaker, motor, relay or frequency converter etc, adopt the brands like Siemens, Schneider or Omron. Thus, the performance is rather reliable. In addition, both screw and screw barrel are made of 38CrMoAlA material, the surface of which is processed by nitrogen treatment and possesses the thickness range from 0.4 to 0.7mm and the hardness of above 940HV. Therefore, both outstanding usability and long service life can be effectively guaranteed.

Performance Parameters

| Extruder | |||||

Stage1 | Stage2 | Stage3 | Stage1 | Stage2 | Stage3 | |

Model | FSJ-120X33 | FSJ-120X7 | FSJ-120X13 | FSJ-150X23 | FSJ-150X7 | FSJ-150X13 |

Screw Diameter (mm) | 120 | 120 | 120 | 120 | 120 | 120 |

L/D | 23:1 | 7:1 | 13:1 | 23:1 | 7:1 | 13:1 |

Max. Speed (rpm) | 90 | 90 | 90 | 90 | 90 | 90 |

Motor Power (kW) | 160 | 18.5 | 55 | 220 | 22 | 90 |

Heating Style | Electric-magnetic heating system | Electric-magnetic heating system | ||||

Heating Power (kW) | 30 | 10 | 15 | 40 | 15 | 20 |

Heating/Cooling Zones | 5 | 2 | 3 | 5 | 2 | 3 |

Max. Output (kg/h) | 800 | 800 | 800 | 1200 | 1200 | 1200 |

Related Names

Three-Stage Vented Plastic Extruder | Vent Style Plastic Extruding Machine | Filtering Extrusion Machinery

Links:https://globefindpro.com/products/87191.html

-

UV Curable Ink

UV Curable Ink

-

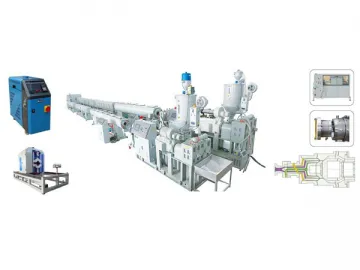

PVC Double and Four Pipe Extrusion Line

PVC Double and Four Pipe Extrusion Line

-

T Series Solvent Ink

T Series Solvent Ink

-

GJ Series Solvent Ink

GJ Series Solvent Ink

-

UV1325S UV Curable Flatbed Printer

UV1325S UV Curable Flatbed Printer

-

UV1209C UV Curable Flatbed Printer

UV1209C UV Curable Flatbed Printer

-

Stained Glass UV Flatbed Printer

Stained Glass UV Flatbed Printer

-

PP-R/FRP/PP-R Three Layer Pipe Extrusion Line

PP-R/FRP/PP-R Three Layer Pipe Extrusion Line

-

CJ Series Solvent Ink

CJ Series Solvent Ink

-

UV1209S UV Curable Flatbed Printer

UV1209S UV Curable Flatbed Printer

-

High Efficiency PVC Conical Twin Screw Extruder

High Efficiency PVC Conical Twin Screw Extruder

-

HDPE Large Diameter Hollow Wall Coil Pipe Making Machine

HDPE Large Diameter Hollow Wall Coil Pipe Making Machine