UV1325S UV Curable Flatbed Printer

UV1325S UV Curable Flatbed Printer

The UV1325S UV curable flatbed printer adopts the following seven systems which ensure high-quality printing and secure operation.

1. The isolated regulated power supply system can prevent the outside EMI and avoid messy code, which eliminate defects and improve production efficiency.

2. Resisting the external electromagnetic interference and reducing users’ requirement of power, the anti-EMI power protection system makes Kincolor UV curable flatbed printer more suitable for regions of different power supply. This system also ensures the transmission of signal and increases printing quality.

3. The adopted over-voltage protector can avoid damage caused by external over-voltage to the UV curable flatbed printer and prevent lightning striking and circuit burning, which avoids property loss and improves the machine’s anti-interference ability.

4. The UV light box power cord short circuit protection system will automatically isolate the power supply when unexpected situation occurs. This effectively prevents electricity leakage and avoids injury to operators.

5. The X-axis high-speed mute dual-rail system adopts imported mute slider to avoid noise in high-speed operation, which is beneficial for the long-term stable working of staff. Comfortable working environment also reduces fatigue of operators, improving work efficiency.

6. The Y-axis symmetric dual-rail movement system can withstand greater machine head weight. Even when the UV curable flatbed printer works long hours, picture dislocation will not occur and the print precision is constantly high.

7. The UV lamp system is efficient, mute and radiation proof, truly reducing the cost of using. This system can conduct high-quality reliable curing on UV ink, which meets the requirement of faster printing mode. With the whole UV control system, real-time power control of the UV lamp can be achieved, which automatically reduces more than 50% of the power when the shutter is closed. This lamp system can also substantially reduce the generation of ozone and avoid damage to operators due to high-density ozone. The mute property of this UV lamp system avoids neighbors’ complaint of pump noise, making the UV curable flatbed printer more suitable for façade, high-end proofing room and other high-end users. Due to the low power printing of the UV tube, using time is effectively extended, reaching 1,500 to 2,000 hours.

Specifications of the UV Curable Flatbed Printer

Product Model | UV1325S |

Print Length | 2.5m |

Print Width | 1.22m |

Model of Print Head | Konica KM512/1024 14pl-35pl-42pl (Japan) |

Number of Print Head | 4-8 pieces |

Maximum Print Precision | 720*2880 DPI |

Print Speed | 8-13-24-50㎡/h |

Color Mode | Four Color-Eight Color |

Application Software | Photoprint DX10.0 KINCOLOR VERSION |

Platform Model | Suction Platform |

Suction Platform Area | 4 Design |

Material Thickness | 0mm-70mm |

Color Range | 16.8 Million |

Print Material | PE, PP, ABS, PS, PETG, PU, PVC, PVB, Metal, Glass, Wallpaper, Leather, Acrylic, Wooden Board, etc. |

Image Format | TIFF/JEPG/BMP/PDF/AI/EPS/PSD/CDR |

Print Technology | Piezo Print Technology |

Positioning Mode | Ink Dot Search Positioning System (Double Closed Loop) |

UV Curing System | Integration Technology/Imported HOENLE UV Curing System/Self-developed UV Curing System |

Print on X-axis Direction | Bidirectional and Unidirectional Printing |

Print on Y-axis Direction | Unlimited Number of Repeat Printing |

Maintenance of Print Head | Automatic Cleaning and Ink Cleaning |

Ink Supply System | World Famous Brand of SMC Negative Pressure Ink Supply System or Mute Negative Pressure System |

Output Port | USB |

Power Requirement | 50/60HZ 220V(±10%)>15A |

Package Size | 4.25m x1.95m x1.68m |

Gross Weight | 1,100kg |

Safety Measures | Several newly developed security systems are added, making people and machine more secure |

Links:https://globefindpro.com/products/87196.html

-

UV1209C UV Curable Flatbed Printer

UV1209C UV Curable Flatbed Printer

-

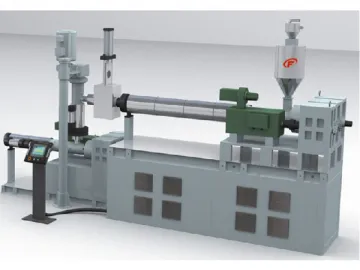

HDPE Water Supply and Gas Pipe Extrusion Line

HDPE Water Supply and Gas Pipe Extrusion Line

-

Tile Digital Inkjet Printer

Tile Digital Inkjet Printer

-

Eco Solvent Ink

Eco Solvent Ink

-

Aluminum Box

Aluminum Box

-

PK Series Solvent Ink

PK Series Solvent Ink

-

GJ Series Solvent Ink

GJ Series Solvent Ink

-

T Series Solvent Ink

T Series Solvent Ink

-

PVC Double and Four Pipe Extrusion Line

PVC Double and Four Pipe Extrusion Line

-

UV Curable Ink

UV Curable Ink

-

Three Stage Venting and Filtering Plastic Extruder

Three Stage Venting and Filtering Plastic Extruder

-

Stained Glass UV Flatbed Printer

Stained Glass UV Flatbed Printer