Induction Explosion Proof Light

Induction ExplosionProof Light

Induction explosion proof light is widely used as an interior lighting facilityin gasoline station, gas station, railway station, subway, workshop, controlroom, etc. Our product hasexcellent performance in dust proofness and corrosion resistance. The outerhousing is formed by overall welding of cold-roll steel sheets. Its surfacesare treated by electrostatic spray. The lamp cover is made from toughened glassand fixed by stainless-steel exposed fasteners.

Specifications

| Item No. | HLG316 |

| Power | 80-250W |

| Input voltage | 110VAC / 220VAC |

| Frequency | 50 / 60Hz |

| Operation temperature | -30 ~ 50℃ |

| Power factor | ≥ 0.98 |

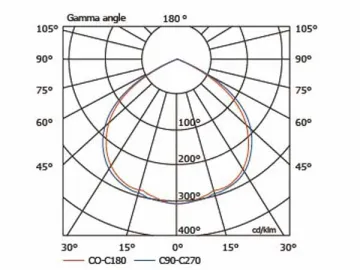

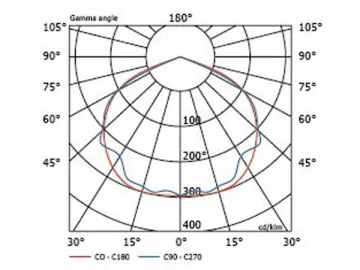

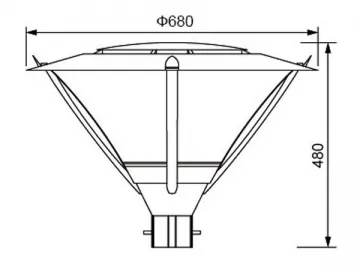

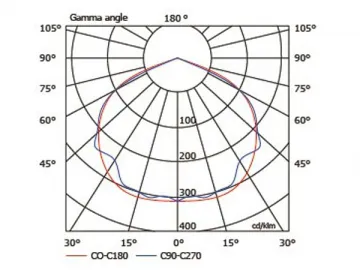

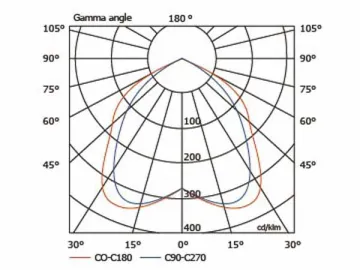

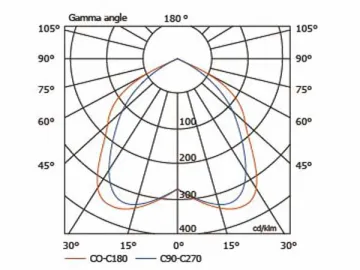

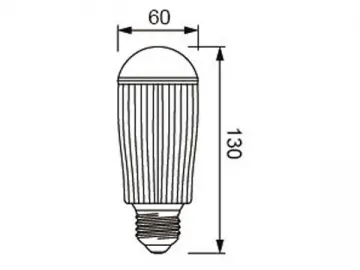

Dimension (mm) and Photometric Curve

Lamp and Ballast

Our induction wall light is equipped with our circular induction lamp, whichfeatures high lighting efficacy, long lifetime, good color rendering, andstable output. Our electronic ballast has advantages of high power factor(>0.98), no flash, low loss, and constant output.

Parameters

| Wattage | Luminous Flux (Lm) | Efficiency (Lm/w) | Color Temperature (K) | CRI (Ra) | Lumen Maintenance (2000H) (%) | Life (H) |

| 80W | 5600 | 70~75 | 2700~6500 | ≥ 80 | ≥ 93 | 100,000 |

| 120W | 9000 | 75~80 | 2700~6500 | ≥ 80 | ≥ 93 | 100,000 |

| 150W | 11250 | 75~80 | 2700~6500 | ≥ 80 | ≥ 93 | 100,000 |

| 200W | 16000 | 80~85 | 2700~6500 | ≥ 80 | ≥ 93 | 100,000 |

| 250W | 20000 | 80~85 | 2700~6500 | ≥ 80 | ≥ 93 | 100,000 |

The surfaces of the outer housing is treated withelectrostatic spray to obtain wear and corrosion resistance. The toughenedglass lamp cover has an anti-impact strength 3-5 times of common glass. It hasa high thermal stability, able to endure 200℃ temperature variation. Even if thelamp cover is broken by an ultra-strong impact, the obtuse angle pieces willnot cause human injury.

Links:https://globefindpro.com/products/87502.html

-

HLG475 250W Induction Industrial High Bay Lighting

HLG475 250W Induction Industrial High Bay Lighting

-

Induction Plant Growing Light

Induction Plant Growing Light

-

Induction Garden Light

Induction Garden Light

-

Induction Tunnel Light

Induction Tunnel Light

-

Oilfield Decanter Centrifuge

Oilfield Decanter Centrifuge

-

HLG475 120W High Bay Induction Light

HLG475 120W High Bay Induction Light

-

HLG422 150W Industrial Induction Light

HLG422 150W Industrial Induction Light

-

HLG469 200W Industrial Induction Light

HLG469 200W Industrial Induction Light

-

HLG469 300W Induction Industrial High Bay Lighting

HLG469 300W Induction Industrial High Bay Lighting

-

LED Light Bulb

LED Light Bulb

-

HLG443 150W Industrial Induction Light

HLG443 150W Industrial Induction Light

-

HLG469 250W Induction Industrial High Bay Lighting

HLG469 250W Induction Industrial High Bay Lighting