Vertical Cutting Dryer

Vertical Cutting Dryer

Due to the strict requirements on environment, drilling waste management is becoming more and more important nowadays, and our company has been concentrating on this field for a long time. Up to 2011, our company is the only Chinese manufacturer that gained API and ISO certificates for the vertical cutting dryer. Our vertical cutting dryer takes advantage of centrifugal force to dry drilled solids in oil or synthetic base fluids. During working, the screen bowl made of stainless steel traps “wet” solids and accelerates them up to 900RPM with G force of 420. As a result, liquid is forced through the screen bowl openings, while “dry” solids are extracted by the angled flights attached to the cone, which rotates slightly slower than the bowl. On the other hand, tungsten carbide is applied to protect the flights from abrasive solids, so the long service life is guaranteed. This contributes to the maintenance of constant gap between the scroll and screen bowl, which is very important for operation. Meanwhile, our machine can be equipped to individual oil lubrication system with automatic alarm for pressure limit. Furthermore, the main motor and oil pump motor are interlocked together, thus the main motor won’t start before oil pump motor. Major rotary components of vertical cutting dryer have passed strict balance test to minimize vibration and noise, and this product is the perfect choice for oil based drilling waste management.

Technical Parameters

Model | GNCD930 |

Feed Capacity | 30~50 tons/h |

Max. Bowl Diameter | 930mm |

Screen Opening | 250/350/500 microns |

Rotation Speed | 890RPM |

G Force | 420 |

Main Motor Power | 45kW |

Oil Pump Motor Power | 7.5kW |

Dryless Efficiency | ≤5% |

Dimension | 2780×2080×2450mm |

Weight | 4500kg |

Links:https://globefindpro.com/products/87513.html

-

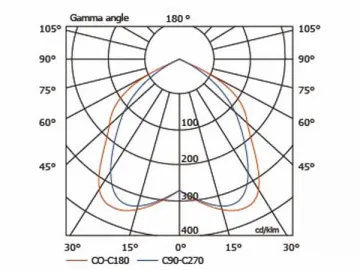

HLG465 200W Industrial Induction Light

HLG465 200W Industrial Induction Light

-

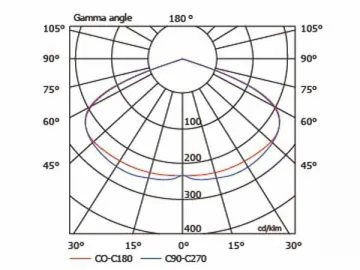

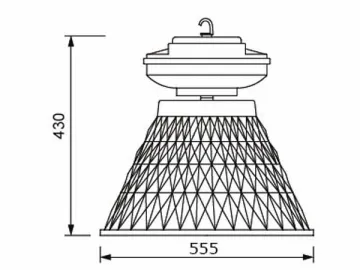

HLG469 120W High Bay Induction Light

HLG469 120W High Bay Induction Light

-

HLG443 200W Industrial Induction Light

HLG443 200W Industrial Induction Light

-

HLG422 200W Industrial Induction Light

HLG422 200W Industrial Induction Light

-

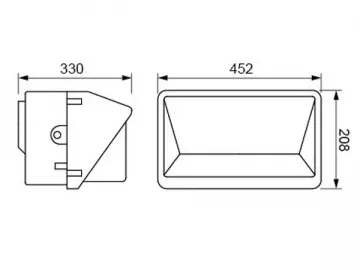

Induction Wall Light

Induction Wall Light

-

Hook Strip Flat Shaker Screen

Hook Strip Flat Shaker Screen

-

HLG475 150W Induction Industrial Light

HLG475 150W Induction Industrial Light

-

Vacuum Degasser

Vacuum Degasser

-

250W Induction High Bay Industrial Lighting

250W Induction High Bay Industrial Lighting

-

HLG475 120W High Bay Induction Light

HLG475 120W High Bay Induction Light

-

Oilfield Decanter Centrifuge

Oilfield Decanter Centrifuge

-

Induction Tunnel Light

Induction Tunnel Light