Hook Strip Flat Shaker Screen

Hook Strip Flat Shaker Screen

The hook strip flat shaker screen is frequently used in oil drilling process under different conditions. It consists of 2 to 3 layers of stainless steel screen meshes which are adhered to the metal lining with hole tightly. In possession of rich production experience and matured technology, we can produce the product of different kinds in dimension to satisfy the requirements of customers.

Technical Parameters

Brand and Model of Shaker | Mesh | Dimension (L×W×H) | Approx. Weight | Number of Layer | Screen Material | Frame Material |

MI-Swaco ALS | API 20 -API 400 | 1143×1213mm | 7kg | 2 or 3 | SS304 | Carbon Steel |

Derrick FLC500 Series | API 20 -API 400 | 1050×695mm | 6.0kg | 2 or 3 | SS304 or SS316 | Carbon Steel |

Derrick FLC2000 Series | API 20 -API 400 | 1053×697mm | 4.2kg | 2 or 3 | SS304 | Carbon Steel |

Note: We list the product of all types in the table. The weight in the table shows average level of the product with same type. The dimension of the product comes from customers and the detailed information about the product can be adjusted in accordance with the requirements of customers.

The hook strip shaker screen has many advantages. Due to the difference in mesh number of the screen meshes, the user can get more excellent screening effect by using the screen meshes with . The metal lining is designed with different hole

Meanwhile, the integration of the bottom coarse wire mesh with small mesh number and metal lining enhances the strength of the whole product and prolongs its lifetime effectively. The grid on the metal lining of the product divides the screen mesh into multiple independent small meshes, which can avoid local damage and excessive expansion. In addition, the product is furnished with special rubber plug which is used for repairing damage. This design can save time and reduce use cost.

Links:https://globefindpro.com/products/87522.html

-

Drilling Mud Gas Separator

Drilling Mud Gas Separator

-

HDD & CBM Mud Recycling System

HDD & CBM Mud Recycling System

-

Drilling Fluid Desander

Drilling Fluid Desander

-

Drilling Mud Gun

Drilling Mud Gun

-

Flare Ignition Device

Flare Ignition Device

-

Drilling Mud Agitator

Drilling Mud Agitator

-

Induction Wall Light

Induction Wall Light

-

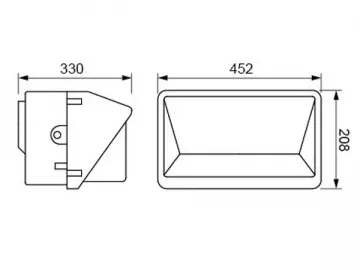

HLG422 200W Industrial Induction Light

HLG422 200W Industrial Induction Light

-

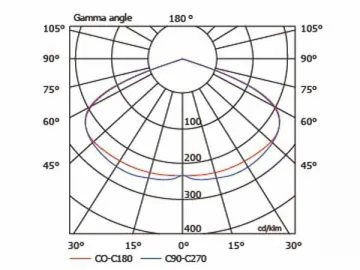

HLG443 200W Industrial Induction Light

HLG443 200W Industrial Induction Light

-

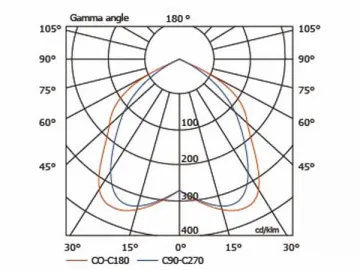

HLG469 120W High Bay Induction Light

HLG469 120W High Bay Induction Light

-

HLG465 200W Industrial Induction Light

HLG465 200W Industrial Induction Light

-

Vertical Cutting Dryer

Vertical Cutting Dryer