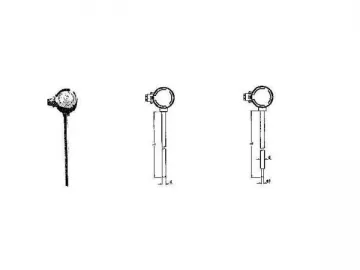

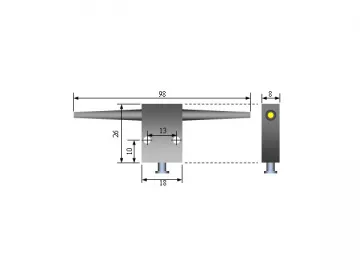

Explosion Proof Thermocouple

In addition, our thermocouple varies various explosion proof models. Thus it can be used with explosives such as hydrocarbon. It is usually connected to a display meter, recording meter and computer, etc. You can directly measure the temperature of liquid, vapor, gas and solid surface.

Certificates

Explosion-proof Class | Certificate No. | Certifying institution |

d Ⅱ BT4 | GTB96450 | NEPSI |

d Ⅱ BT4 | GTB96453 | NEPSI |

d Ⅱ CT5 | GTB98339 | NEPSI |

d Ⅱ CT5 | GTB97197 | NEPSI |

ia Ⅱ CT6 | GTB99412 | NEPSI |

Tolerance

Type | Graduation | Tolerance Class | |||

I | II | ||||

Tolerance Value | Measuring Range °C | Tolerance Value | Measuring Range °C | ||

WRN | K | ±1.5°C | -40 ~ 375 | ±2.5 °C | -40 ~ 333 |

±0.004ltl | 375 ~ 1000 | ±0.0075 ltl | 333~1200 | ||

WRM | N | ±1.5°C | -40 ~ 375 | ±2.5°C | -40 ~ 333 |

±0.004 ltl | 375 ~ 1000 | ±0.0075 ltl | 333 ~ 1200 | ||

WRE | E | ±1.5°C | -40 ~ 375 | ±1.5°C | -40 ~ 333 |

±0.004 ltl | 375 ~ 800 | ±0.004 ltl | 333 ~ 900 | ||

WRF | J | ±1.5°C | -40 ~ 375 | ±1.5°C | -40 ~ 333 |

±0.004 ltl | 375 ~ 750 | ±0.004 ltl | 333 ~ 750 | ||

WRC | T | ±1.5°C | -40 ~ 125 | ±1°C | -40 ~ 133 |

±0.004 ltl | 125 ~ 350 | ±0.0075 ltl | 133 ~ 350 | ||

Indication of Explosion-proof

Temperature Group: T1-T6

Explosion-proof Class: A, B, C

Electric Equipment for plant

Explosion Separation Type

Intrinsic Safety Type

Temperature Group

It includes T1-T6 according to maximum surface temperature allowed of open part.

Temperature Group | Max. Surface Temperature Allowed |

T1 | 450 |

T2 | 300 |

T3 | 200 |

T4 | 135 |

T5 | 100 |

T6 | 85 |

Naming Method

W  | Temperature instrument | |||||||

R | Thermocouple | |||||||

Thermal Element Material | ||||||||

M | NiCrSi-NiSi | |||||||

N | NiCr-NiSi | |||||||

E | NiCr-CuNi | |||||||

F | Fe- CuNi | |||||||

C | Cu- CuNi | |||||||

Filament | ||||||||

blank Simplex | ||||||||

2 | 2 Duplex | |||||||

Mounting &fixing | ||||||||

1 Without fixing device | ||||||||

2 Threaded connector | ||||||||

4 Fixed flange | ||||||||

5 Elbow tube connector | ||||||||

7 Straight tube connector | ||||||||

8 Fixed threaded tube connector | ||||||||

9 Movable threaded tube connector | ||||||||

| Junction box | |||||||

4 Explosion-proof Type | ||||||||

| Protection Tube Diameter | |||||||

| 0Φ16 | |||||||

Measuring End G Variable cross section | ||||||||

W | R | N | 2 | 2 | 4 | G | Model example | |

Links:https://globefindpro.com/products/89060.html

-

Level Measuring Pressure Transmitter

Level Measuring Pressure Transmitter

-

Industrial Explosion Proof Pressure Transmitter

Industrial Explosion Proof Pressure Transmitter

-

Differential Pressure Meter

Differential Pressure Meter

-

Sanitation Diaphragmatic Pressure Meter

Sanitation Diaphragmatic Pressure Meter

-

Magnetic Level Meter

Magnetic Level Meter

-

Radar Level Meter

Radar Level Meter

-

Thermal Mass Flow Meter

Thermal Mass Flow Meter

-

Open Channel Ultrasonic Level Meter

Open Channel Ultrasonic Level Meter

-

24W White Amber LED Bar Light

24W White Amber LED Bar Light

-

Water Pressure Switch

Water Pressure Switch

-

3W E27 LED Bulb Light

3W E27 LED Bulb Light

-

Collimator Variable Optical Attenuator

Collimator Variable Optical Attenuator