Electrothermal Melting Insulation Furnace

Electrothermal Melting Insulation Furnace

The electrothermal meltinginsulation furnace is mainly used by die-casting and pouring company in meltingand temperature preservation of non-ferrous metal with low melting point suchas aluminum, zinc, and correlated alloy. It has theadvantages of fast heating speed, good thermal insulation, easy operation,energy saving, and environmental protection due to the new type energy-savingfull cotton furnace lining, resistance wire or silicon carbide rod heating method,PID intelligent temperature control system, SCR module control system, andlinear output method adopted.

Theproduction cycle is 40 days.

Technical Specification

| No. | Item | Unit | Model | ||

| GR2-40-9 | GR2-60-8 | GR2-7-8 | |||

| 1 | Rated Power | KW | 40 | 60 | 75 |

| 2 | Maximum Temperature | ℃ | 950 | 1200 | 850 |

| 3 | Service Temperature | ℃ | 850 -1200 | 850-1200 | 850 -1200 |

| 4 | Rated Voltage | V | 380 | 380 | 380 |

| 5 | Phase |

| 3 | 3 | 3 |

| 7 | Size of Crucible | mm | 300×430 | 500×600 | 500×870 |

| 9 | Heating Time of Empty Furnace | h | <=2 .5 | <=2 .5 | <=2 .5 |

| 10 | Melting Aluminum Capacity | ㎏ | 54 | 150 | 270 |

| 11 | Outline Size | mm | 950×1200 | 1290×1380 | 1350×1710 |

| 12 | Weight | ㎏ | 1500 | 1740 | 2300 |

This electrothermal melting insulation furnace can acquire service temperatureranging from 850℃ to 1,200℃in 2.5 hours with resistance wires or silicon carbide rods. The working voltageis 380V. We provide three models with different furnace sizes and meltingaluminum capacity to help customers reasonably save their power consumption.The intelligent temperature controlling design also helps to save useroperations and maintenance costs, thus controlling the human labor cost whilecreating a safe and efficient environment.

Links:https://globefindpro.com/products/89461.html

-

Shaped Glass Edging Machine

Shaped Glass Edging Machine

-

Electrothermal Decorative Glass Bending Furnace

Electrothermal Decorative Glass Bending Furnace

-

Glass Washer Drier Machine

Glass Washer Drier Machine

-

Roller Domestic Ceramic Decorating Kiln

Roller Domestic Ceramic Decorating Kiln

-

Electric Heating Coil, Ribbon Heater

Electric Heating Coil, Ribbon Heater

-

Atmosphere Experimental Electric Furnace

Atmosphere Experimental Electric Furnace

-

Ceramic Fiber Board, Insulation Cotton

Ceramic Fiber Board, Insulation Cotton

-

X Ray, Gamma Ray Protective Lead Room

X Ray, Gamma Ray Protective Lead Room

-

Medical Protective Door

Medical Protective Door

-

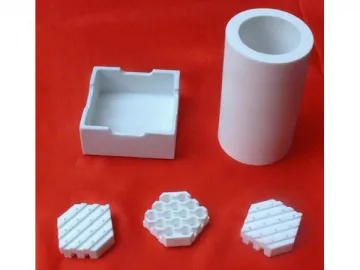

Insulating Brick, Refractory Brick, Crucible

Insulating Brick, Refractory Brick, Crucible

-

Electronic Ceramic Ignition Products

Electronic Ceramic Ignition Products

-

TIG-315 Industrial Inverter DC TIG Welding Machine

TIG-315 Industrial Inverter DC TIG Welding Machine