Roller Domestic Ceramic Decorating Kiln

Roller Domestic Ceramic Decorating Kiln

The roller domestic ceramic decorating kiln is applied in decoratingfiring and overglaze decoratingfor domestic ceramic and art ceramic, and decorating and drying of glasswork.The production cycle is 40 days, and the maximum temperature is 1,100℃.

Technical Specification

| Length of Furnace | 30-60m, segmental |

| Cross Section of Furnace Mouth | 800mm-2,000mm |

| Daily Decorating Output (24h) | 3,000-35,000 sets |

| Maximum Service Temperature | 1,100℃ (adjustable) |

| Electric Power | 90-350 (kW/380V) |

| Heating Element | Electrothermal alloy wires |

| Temperature Controlling Method | PID intelligent digital display temperature controlling, SCR module controlling, linear scale output, with automatic constant temperature controlling, overheating alarm, and manual/automatic controlling functions. |

| Temperature Controlling Point | 8-12 points |

| Rollers | φ40-80mm alumina ceramic rollers |

| Driving Method | Helical Gears |

The roller domestic ceramic decorating kiln can make colorful and vividpatterns on art ceramic and domestic ceramic such as ceramic tableware andceramic tea set. The processed ceramic products are popular among theconsumers. It comes with highly accurate temperature controlling system. Thedecorating temperature can be kept constant according to users’ settings. Onoverheating events, the alarm will be triggered. The intelligent decorating processcan not only achieve higher efficiency, but also save human labor. We providevarious models to help you reduce costs and increase profits.

Links:https://globefindpro.com/products/89465.html

-

Electric Heating Coil, Ribbon Heater

Electric Heating Coil, Ribbon Heater

-

Atmosphere Experimental Electric Furnace

Atmosphere Experimental Electric Furnace

-

TIG-250 Inverter DC TIG Welding Machine

TIG-250 Inverter DC TIG Welding Machine

-

TIG-400 Industrial Inverter DC TIG Welding Machine

TIG-400 Industrial Inverter DC TIG Welding Machine

-

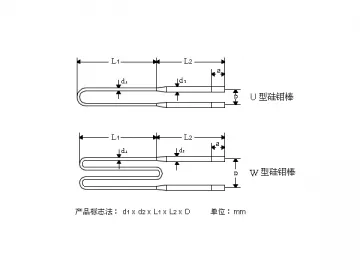

Silicon Molybdenum Rod

Silicon Molybdenum Rod

-

TIG-500 Industrial Inverter DC TIG Welding Machine

TIG-500 Industrial Inverter DC TIG Welding Machine

-

Glass Washer Drier Machine

Glass Washer Drier Machine

-

Electrothermal Decorative Glass Bending Furnace

Electrothermal Decorative Glass Bending Furnace

-

Shaped Glass Edging Machine

Shaped Glass Edging Machine

-

Electrothermal Melting Insulation Furnace

Electrothermal Melting Insulation Furnace

-

Ceramic Fiber Board, Insulation Cotton

Ceramic Fiber Board, Insulation Cotton

-

X Ray, Gamma Ray Protective Lead Room

X Ray, Gamma Ray Protective Lead Room