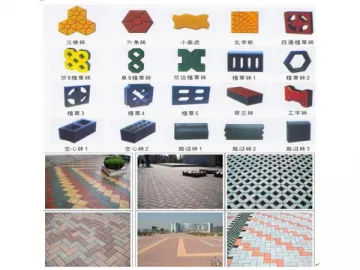

Concrete Brick and Concrete Block Making Machine

Concrete Brick andConcrete Block Making Machine

Our concrete brick and concrete block making machine is a brick makerwhich collects the traits that economical, efficient and environmental. Itconsists of electronics system, hydraulic system and vibration &compression molding device. It features forced spreader and vibration benchthus it can at maximum spread the mixed material in mould evenly. Only using the importedelectronic components and uniform hydraulic device, this brick making machineis guaranteed to run continuously and safely.

Features

1. This concrete brick andconcrete block making machine creatively adopts photoelectric system to controlthe storage of material and the material can be ensured to reach the moldingpart in time. Thus the risk of extra liquefaction has been removed.

2. This machine also can change the extra hydraulic fluid into the energyof strike force required by other parts of machine and use computer to exactlycontrol this procedure.

3. This brick making machine professionally adds a swing type feedingdevice to hopper feeder. User is supposed to control the feeding quantitythrough a swing fork to make sure the raw material is fed evenly.

4. This concrete brick making machine is smart. It is equipped with Mitsubishibranded PLC, a touch human-machine interface, vital logic controller and faultdiagnostic system. This brick making machine can be full manual controlled,half manual controlled or full automatic controlled. User is supposed to addthe orders of move into PLC rather than add workerssimply. The parameter of each handling part can becustomized. By this way our brick making machine can ensure the standard andquality brick making.

5. This brick making machine is heavy-structure designed. Its structure is madeof cast steel and welded in special way. This kind of particular steelstructure can ensure the stiffness and weight the machine requires. In additionthis outstanding design can efficiently avoid the resonance caused by highspeed running to extend the life of whole device.

6. The storage & feeding device of our machine adopts sealed belttransmission. It handles exactly the storage of raw material and removes theliquefaction risk of concrete caused by left vibration.

7. The special vibration mode adopted by our machine utilizes computer tocontrol the flow and pressure of hydraulic system and vertical Synchronousvibration, frequency conversion and brake. This application makes it possiblefor concrete to fully liquefy and air void in a very short time within 2-3min.

8. The double end synthesis vibration technology gives the machine reasonablevibration distribution. Its mold jacket is fixed upon the vibration bench andvibrates together with the bench. Press head has another special vibrator on itin order to magnifythe vibration effect. By this way the machine can liquefy the concrete quickand amazingly intensive.

9. This concrete brick and block making machine is used widely inrecycling all kinds of dust cinder crushed ore and stone industrial trash.

10. By special arch breaker, the raw material can be fed evenly into moldjacket. And based on the double endsynthesis vibration technology, the vibration power can be spread evenly inevery spot of mold jacket to make sure the same quality and weight of each partof a brick.

11. Hydro-mechatronicsdesign gives this burn-free brick making machine excellent precisenessstability and high performance.

Mainbody:

Parameters of KBQ6-15 Concrete Brick and Concrete Block MakingMachine

| Molding speed | 15-18s | Output per mould |

| Vibration frequency | 1200-4200 times / min or customized | 240×115×53 mm (Standard bricks ) ×30 |

| Excitation force | 20-50N or customized | 390×190×190mm (block bricks) ×6 |

| General power | 36.5 KW | 240×115×90 mm (perforated bricks) ×18 |

| Ideal daily output | 72000 brick (Standard bricks ) | 250×250×60 mm (pavement bricks ) ×6 |

| Size of plate made of bamboo | 1050×560×30-35mm | 225×111×60 mm (pavement bricks ) ×18 |

| Weight | 10.8T | 200×100×60 mm (18 bricks ) |

| Size | 3200×1900×2600mm |

|

:

Links:https://globefindpro.com/products/89610.html

-

PS240 Airless Painting Machine

PS240 Airless Painting Machine

-

KB-MJ 400 Polishing Machine

KB-MJ 400 Polishing Machine

-

Donut Shaped Lip Gloss / Lip Balm

Donut Shaped Lip Gloss / Lip Balm

-

Shoes Shaped Lip Gloss / Lip Balm

Shoes Shaped Lip Gloss / Lip Balm

-

Terrazzo Tile Making Machine

Terrazzo Tile Making Machine

-

Soda Can Lip Balm

Soda Can Lip Balm

-

Tube Lip Balm

Tube Lip Balm

-

Pudding Shaped Lip Gloss / Lip Balm

Pudding Shaped Lip Gloss / Lip Balm

-

New Cupcake Shaped Lip Gloss / Lip Balm

New Cupcake Shaped Lip Gloss / Lip Balm

-

Light Up Lip Gloss Wand

Light Up Lip Gloss Wand

-

Natural Shine Lip Gloss Wand

Natural Shine Lip Gloss Wand

-

16 Piece Cosmetic Set

16 Piece Cosmetic Set