Screw Conveyor

Screw Conveyor

Our screw conveyor can be used in manymanufacture fields including building materials, chemical, power, metallurgyand agricultural industries. It can be used both in transmission of powder andsmall block materials such as coal ash dreg cement and corns.

Features

1. Our screw conveyor adopts the helicalstructure to convey the materials. Thisstructure helps to mix and blend the material during the process oftransmission. According to the feature of different material, User can choosethree types of blade, entity band or leaf. The leaf type blade is used mainlyin transferring the viscous and compressible material of the machine.

2. The screw axis and hanger axis of the screw conveyer are all end-embedded.That makes the maintenance and dismantlement quite simple. Besides that the mandrel of the machine has asimple design and less trouble spots.

2. With variable diameter structure and enhanced capacity of suspensionbearing, the bearing of this screw conveyer can be apart from material andextend its life to two years or more.

3. The mechanical system of the screwconveyer can ensure fluent transmission. Each transmission part is combinedwith each other in a suspension joint way. The main suspension bearing isuniversal joint structural to make itself and the tail assembly a suspendingsystem. Thus in a certain scope, the inner parts can avoid the materialflexibly due to the force.

4. The bearing we adopted has long serving life. The housings of head bearingand tail bearing are both out of the enclosure of machine. Both the bearings are multilayer and matchingsealed.

5. The actuating device consists of sealed slot box and screw. The machinepropels the coal, ash, etc with the rotation of screw. During the process theuser is able to stir blend heat and cool the stuff, control the transmissionspeed by valve. Working in this way, the screw conveying machine is able to ownsmaller size but higher efficiency.

|6. Our vertical screwconveyor is used in vertical transmission for short distance. Our machine featuring flexible axis andrubber blade can fit well in any industrial field. The blade we used has twospecifications, one is instant type which can be customized in thickness andsize and the other one is fixed type.

7. This machine we offered has traits of simple structure, economic, goodsealing and easy operation. It is wise of user to utilize the equipment withthe dip angle less than 20

Cautions

1. This screw conveyor should start without loadin and be fed only when it is running.

2. User should enhance the feeding speed gradually and evenly until reachingthe rated transfer capacity of the conveyor. Nevertheless the machine isthought to be blocked and overrun and no doubt the life of the machine willgoes out sooner.

3.In order to ensure the machine can start with no load, user is supposed tomake sure there is nothing left in the conveyor when he or she shut themachine.

4. User should keep the hard or massive parts out of fed material so as toremove the risk of the screw conveyor breaking down.

5. It is wise to check the status of every part of the running machine frequentlyand remove the risk of loose fasteners

6. Much attention should be paid to the screw ring of the bolt which fixes thescrew tube. Any hidden danger should be removed.

7. The cover of screw conveyer is prohibited to be moved when the machine isrunning.

8. User ought to add Lubricant to the connections of screw conveyerregularly.

9. Our conveyor is not suitable for transmission of the viscous materials orthe stuff that is easy to agglomerate or go bad, because the above things mayadhere to the screw and move with it to cause the blocking of the bearing andfailure of whole machine.

10. User is advised to start and shut the machineproperly. When switching on the machine, user must make sure the powerindicator light is on. When switching off, user must make sure the machine hasstopped e.g. the indicator light of belt transmission and variable-frequencydrive is off, the monitor shows nothing eccentric.

11. The electronic devices of this machine should be started one by one. Onlythe one before has been ensured to work normally can the next device be opened.

12.Unprofessional people areforbidden to touch the running belt transmission, electronic components, andcontrol button. Finally, if the operator intends to maintain the conveyor,he or she can not cut the power of variable frequency device partly. It is wiseto shut the it wholly and go on maintenance.

13. when several screwconveyors are in line running, user is advised to start the machines from theoutlet one in order. When all the machines are running normally, user can feedmaterial safely.

14. In case the rubber belt runs out of rail, user should stop the machineinstantly in order to protect the rubber belt.

15. The type and quantity of material must be available for conveying throughthe machine. When the machine is running, the temperature of circumstance mustbe no higher than 50℃and the temperature of fed material must be no lower than -10℃ or higher than 200℃. The fed material isforbidden to have acid, alkalicoil or Organicsolvent composition

16. No humanity stands upon the belt transmission.

17. User must make sure the motor of the machine insulating. When using ourportable screw conveyor, user must keep the wire trim and the motor safe.

18. In case the belt is slipping, user is prohibited to pull it by barehand.

Links:https://globefindpro.com/products/89633.html

-

PVC Roofing Special Silicone Sealant

PVC Roofing Special Silicone Sealant

-

Kerb Stone / Curbstone / Road Edge Stone Making Machine

Kerb Stone / Curbstone / Road Edge Stone Making Machine

-

Senior Flooring Silicone Sealant

Senior Flooring Silicone Sealant

-

Large Aquarium Special Acid Silicone Sealant

Large Aquarium Special Acid Silicone Sealant

-

KB125Z-600 Terrazzo Tile Making Machine

KB125Z-600 Terrazzo Tile Making Machine

-

Large Plate Glass Special Acid Silicone Sealant

Large Plate Glass Special Acid Silicone Sealant

-

Pavement Brick and Concrete Block Making Machine

Pavement Brick and Concrete Block Making Machine

-

Fruit Shaped Lip Gloss / Lip Balm

Fruit Shaped Lip Gloss / Lip Balm

-

Automatic Color Roof Tile Painting Line

Automatic Color Roof Tile Painting Line

-

Russian Doll Shaped Lip Gloss / Lip Balm

Russian Doll Shaped Lip Gloss / Lip Balm

-

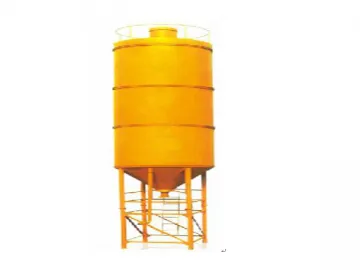

Cement Silo

Cement Silo

-

Lip Balm Stick

Lip Balm Stick