Kerb Stone / Curbstone / Road Edge Stone Making Machine

Kerb Stone / Curbstone / Road Edge Stone Making Machine

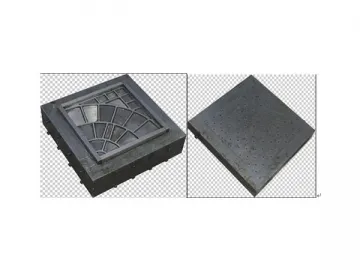

Our Kerb stone making machine is also commonly calledcurbstone making machine or road edge stone making machine. It utilizes sand, industrial residue,cinder, slag, etc to make the raw material of road pavement. With a littlecement, the raw material can be molded to all types of road-edge stone, colorbrick, road-edge brick, lawn brick, permeable brick, special brick, etc by thisroad-edge stone machine. The mould of machine is replaceable. The stone andbrick made by this machine are suitable for the road, road, square, highway,etc pavement, which greatly improves the city's ecological environment andbeautify urban circumstance by preventing the water and soil loss.

This new mechanical facility of this machine can produce the stone and brickwithin one meter of length. E.g. hexagonal brick, lawn brick, slope protectionbrick, road-edge stone. The whole procedure from raw materials to finishedproducts is fully automatic and simple. The product structure is simple,reasonable designed. The machine has less weight lower noise but higherperformance in working and energy saving.

Suggestions

Take the self-consumption ofmachine parts into consideration when you purchase the equipment. E.g. the coston changing wooden plate and mould, maintain fare, material cost and laborcost.

The Proper investment is wise. For cement productsmaking has little science and technology value inside, the industrialcompetition is quite a fever now. We advise the buyers to choose a properinvestment in equipment purchase and infrastructure constructionor there will be a risk. The buyer should think about the funds site market andlater cost on equipment. If user chose the exceeding size of investment, it maylead to a production cease and laid-off workers. Our small and medium sizedmachine can also make the good cement and concrete products. Investor also canbenefit quickly by smaller investment if the skilled worker can be kept.

Features

1.Ourroad-edge stone making machine is equipped with branded Mitsubishi control systemand human machine interface to make operation easy. Besides the otherelectronic parts of machine are all from famous supplier. Thus it can beself-monitored to make terrazzo floor tile.

2. The mould of machine is replaceable. Users can use the machine to maketerrazzo road edge stone and curb stone and use polisher to make the stone looklike marble. Besides, the tonnage of machine can be customized from 250T to800T.

3. The terrazzo road edge stone and curb stone made by this machine isenvironment-friendly and helpful for recycling the waste of industrial andmining enterprise.

4. The machine is able to produce the precise-sized building material that isanti freezing, compression resistant, high strengthand brilliant.

Cautions

1. Daily cleaning is necessary. Powershould be cut off after use. Debug the machine beforeyou use it. Any thing should be kept away when the maker is running. The mixershould be set at a stable place with bracket or feet tubes. Anybody isinterdicted to pass by when hopper feeder is elevated. During maintain thehopper feeder should be in a safe place.

2. Once the oil leakage happened, the Oil cylinder, valve, valve parts, oiltube and other hydraulic parts should be checked and renewed with oil seal orseal ring, etc or whole replaced in case of risky operation. Oil pump oilmotor, etc in operation should be often checked. Please keep the hydraulicsystem, oil pipeline and hydraulic pressure station internal clean. Please keepthe inner space of hydraulic machine oil tube and station clean and attentionthe running temperature to ensure it is not too high.

3. the molding speed shouldbe strictly controlled. According to the characteristic of product user oughtto handle the vibration press time properly and learn about the time ofdifferent product. Adjust the feeding quantity and times to balance. Attentionthe working procedure to avoid accident e.g. tightening the screws.

4. The hydraulic system of stone making machine requires clean hydraulic oil.Road-edge stone machine hydraulic system has many precision pieces, some ofwhich have damping holes, some of which have crack, etc. If some solidimpurities invaded, it would cause precision part accidentally scratched andstuck the oil route jammed and so on. That would doharm to hydraulic system of road-edge stone machine General speaking the causesof solid impurities invasion are e.g. the unclean hydraulic oil, uncleanrefueling tools, error maintenance method, inevitable oil adding, hydrauliccomponents desquamation, etc.

5. This road-edge stone machine requires its corresponding cleaning oil. Whenmaintaining the hydraulic system of this machine, thetemperature of oil is advisable between 45 ℃ ~ 80℃. User is advisable to pour high oilflow in system and take away impurities from system as many as possible.Generally speaking in order to achieve the goal of maintaining, the hydraulicsystem of this machine is advised to be cleaned for three times or more. Afterbeing used, the oil should be totally released from system before it is cooldown. Finally it is time to clean the filter and change the filter core for newhydraulic oil. The core if possible should be branded so that the quality can beensured.

6. User is advised to clean and dismantle the oil case lid, filter cover,inspection part, oil tube in order. Once the inner system is exposed, it isrequired to be away from dust in air. When open the oil box, user should cleanout the adherent mud and dust around the lid of oil box especial the dirtappears after the lid moves a little. A word for caution thewater wash is forbidden. During the procedure of cleaning, if hammer andwiper is in need, user is advised to ensure the bumping face of hammer is coverwith rubber and wiper will not leave any fiber impurity inside. After thehydraulic system of this machine is cleaned, user had better drought off theparts under high pressure fan before reassembling. When user fix the filterplease ensure the filter bottom is cleaned. The hydraulic oil must be filteredand injected into machine by clean injector. In addition the user is unwise toremove the filter to accelerate or wear unclean jacket when injecting oil.

Components:

host machine, lifter, primary spreader, secondary spreader, hydraulic system,transmission belt, mould, brick car, hydraulic station

Technical parameteres:

| Molding pressure | 320T |

| Molding speed | 5-6 tiles / min |

| Main power | 7.5KW |

| Main weight | 8 T |

| AC voltage | customized |

| AC frequency | customized |

:

2()

::1()

Links:https://globefindpro.com/products/89635.html

-

Senior Flooring Silicone Sealant

Senior Flooring Silicone Sealant

-

Large Aquarium Special Acid Silicone Sealant

Large Aquarium Special Acid Silicone Sealant

-

KB125Z-600 Terrazzo Tile Making Machine

KB125Z-600 Terrazzo Tile Making Machine

-

Large Plate Glass Special Acid Silicone Sealant

Large Plate Glass Special Acid Silicone Sealant

-

Kitchen & Bathroom Mould Proof Silicone Sealant

Kitchen & Bathroom Mould Proof Silicone Sealant

-

Aluminum Alloy Windows and Doors Acid Silicone Sealant

Aluminum Alloy Windows and Doors Acid Silicone Sealant

-

PVC Roofing Special Silicone Sealant

PVC Roofing Special Silicone Sealant

-

Screw Conveyor

Screw Conveyor

-

Pavement Brick and Concrete Block Making Machine

Pavement Brick and Concrete Block Making Machine

-

Fruit Shaped Lip Gloss / Lip Balm

Fruit Shaped Lip Gloss / Lip Balm

-

Automatic Color Roof Tile Painting Line

Automatic Color Roof Tile Painting Line

-

Russian Doll Shaped Lip Gloss / Lip Balm

Russian Doll Shaped Lip Gloss / Lip Balm