Centrifugal Concentrator

Centrifugal Concentrator

The LX centrifugal concentrator is anew type of separation machine for mineral ores with density variation. It isenergy efficient, practical, and generates no pollutions. It is commonly usedfor separation and collection of gold, tungsten, lead, tin, manganese, iron anduranium ores, and tombar thite as well. Without lower limitation for feeding material sizes, the centrifugalconcentrator is especially suitable for ultra-fine mineral materials. To allow customers feelsecure in purchasing, the separation equipment is manufactured underISO9001:2008 system standard.

Our centrifugal concentrator is composed of two primary parts. One is thematerial separation mechanism which mainly includes a rotary drum, and theother is the ancillary mechanism which consists of mineral feeding system,mineral discharging system, washing system and control system.

Technical Parameters of the CentrifugalConcentrator

| Model | Drum Dia . ( mm) | Drum Slope ( °) | Drum Speed ( r/min) | Feeding Size ( mm) | Feeding Material Concentration ( %) | Capacity ( m3/h) | Power ( kw ) | Dimension ( mm) | Weight ( kg) |

| LX-Φ800x600 ( Rough) | 800 | 4 | 450 | -0.074 | 15-25 | 1.2-1.5 | 3 | 1920 × 1300 × 2540 | 1100 |

| LX-Φ800x600 ( Fine) | 800 | 5 | 380 | -0.074 | 15-25 | 1.2-1.5 | 3 | 1920 × 1300 × 2540 | 1100 |

| LX-1600 | 1600 | 5 | 105-405 | -0.074 | 15-25 | 1.5-4.5 | 11 | 2900 × 1900 × 3900 | 4500 |

| LX-2000 | 2000 | 5 | 105-405 | -0.074 | 15-25 | 6-7.5 | 17 | 3566 × 2334 × 3900 | 7500 |

| LX-2400 | 2400 | 5 | 105-405 | -0.074 | 15-25 | 5-10 | 22 | 3700 × 2400 × 4100 | 12000 |

The drum of centrifugal concentrators is installed with an inclination angle.When the drum is rotate in a high speed, the ore slurry is fed into the drumfrom two feeding holes. Due to the centrifugal force, the heavy mineral ores stickon the inner wall of the drum, while the light materials will rotate at a lowerspeed along with the rotation of drum. Gradually, the rotating light materialsmove towards the lower end of the drum and finally discharged from adischarging hole. They are the tailings.

When the feeding process continued for three minutes, the centrifugalconcentrator will stop feeding temporarily. When the tailings are dischargedcompletely, high pressure water is supplied to wash away the heavy ores on thedrum wall. The heavy mineral ores are the ore concentrate. When the oreconcentrate is discharged and collected, the centrifugal concentrating machine comesinto the next cycle.

Links:https://globefindpro.com/products/90827.html

-

ESYS-6007 Memory Game Toy

ESYS-6007 Memory Game Toy

-

ESYS-6001 Drum Sound Key Ring

ESYS-6001 Drum Sound Key Ring

-

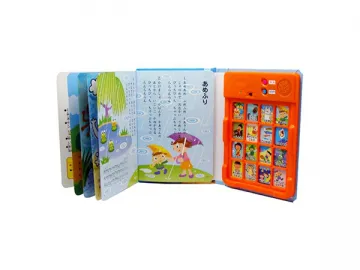

ESYS-3005 Speaking Book

ESYS-3005 Speaking Book

-

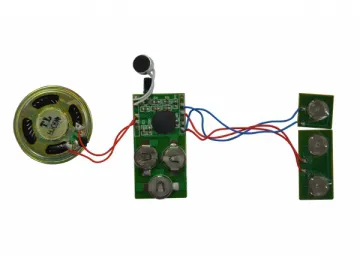

ESYS-2005 Recordable Voice Chip

ESYS-2005 Recordable Voice Chip

-

ESYS-3007 Recordable Sound Book

ESYS-3007 Recordable Sound Book

-

ESYS-1009 Music Press Button

ESYS-1009 Music Press Button

-

ESYS-2006 Recording Voice Module

ESYS-2006 Recording Voice Module

-

ESYS-1002 Animal Sound Box

ESYS-1002 Animal Sound Box

-

ESYS-4006 Music and Dancing Lion Module /Talking Toys

ESYS-4006 Music and Dancing Lion Module /Talking Toys

-

Hydraulic Briquette Machine

Hydraulic Briquette Machine

-

ESYS-1010 Reminder Sound Box

ESYS-1010 Reminder Sound Box

-

Trommel Screen

Trommel Screen