Wet Magnetic Separator

Wet MagneticSeparator

The wet magnetic separator is designed forseparation of iron ores with particle size less than 1mm, including ilmenite,magnetite, pyrrhotite, calcined ore, and more. It isalso regularly used for iron removal in coal, non ferrous metal and buildingmaterial industries. Our wet magnetic separation equipment has characteristicslike simple structure, large separation capacity, simple operation andconvenient maintenance, etc.

To suit customers’ demands,we can offer variety of models of separators with varied magnetic strength, drumspeed, and separation capacity. After ore slurry is fed into the wet magneticseparator via a feeding box, it is then delivered to the magnetic separationzone. Then, mineral ores will be separated due to their varied magneticsusceptibility. Strongly magnetic minerals will adhere to the drum surfacetightly due to the magnetic force, and along with the rotation of drum, theyare transferred to the discharging hole, and finally delivered into oreconcentrate box with the help of clean water. While gangue and mineral oreswith weak magnetism flow in opposite direction to the drum rotation directionand finally are discharged from a pipe. Thus, the wet magnetic separatorfinishes its separation process.

TechnicalParameters of the Wet Magnetic Separator

| Model | Magnetic Strength (mT) | Input Size (mm) | Drum Speed (r/min) | Power (kw) | Capacity | Weight (kg) | |

| Ore (t/h) | Slurry (m3/h) | ||||||

| CTB600x900 | ≥120 | ≤1 | 40 | 1.1 | 8-15 | 24 | 850 |

| CTB600×1200 | ≥120 | ≤1 | 40 | 1.5 | 10-20 | 32 | 1000 |

| CTB600×1800 | ≥120 | ≤1 | 40 | 2.2 | 15-30 | 48 | 1300 |

| CTB750×1200 | ≥120 | ≤1 | 35 | 2.2 | 15-30 | 48 | 1500 |

| CTB750×1800 | ≥120 | ≤1 | 35 | 3.0 | 20-45 | 72 | 1800 |

| CTB900×1800 | ≥135 | ≤1 | 28 | 4.0 | 25-55 | 90 | 2400 |

| CTB900×2100 | ≥135 | ≤1 | 28 | 4.0 | 30-65 | 100 | 2650 |

| CTB1050×1800 | ≥145 | ≤1 | 22 | 5.5 | 35-70 | 110 | 3800 |

| CTB1050×2100 | ≥145 | ≤1 | 22 | 5.5 | 45-88 | 140 | 4150 |

| CTB1050×2400 | ≥145 | ≤1 | 22 | 5.5 | 45-88 | 140 | 4500 |

| CTB1200×2100 | ≥145 | ≤1 | 19 | 7.5 | 62-110 | 160 | 5800 |

| CTB1200×2400 | ≥145 | ≤1 | 19 | 7.5 | 82-120 | 192 | 6200 |

| CTB1200×3000 | ≥145 | ≤1 | 19 | 7.5 | 80-150 | 240 | 6800 |

| CTB1500×3000 | ≥145 | ≤1 | 14 | 11 | 90-170 | 270 | 8200 |

| CTB1500×4000 | ≥145 | ≤1 | 14 | 11 | 115-220 | 350 | 9000 |

Links:https://globefindpro.com/products/90868.html

-

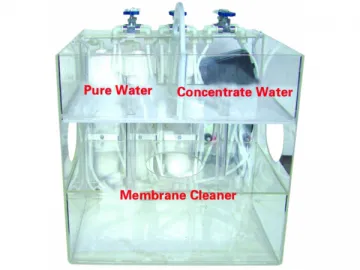

RO Membrane Cleaner

RO Membrane Cleaner

-

Ore Feeding Machine

Ore Feeding Machine

-

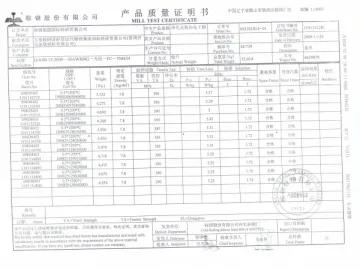

Cold Rolled Steel Sheet

Cold Rolled Steel Sheet

-

100GPD Booster Pump

100GPD Booster Pump

-

RO-I-12000 RO Equipment Water System

RO-I-12000 RO Equipment Water System

-

RO-I-24000 Industrial RO Water System

RO-I-24000 Industrial RO Water System

-

Filter Cartridge

Filter Cartridge

-

Cold Rolled Steel Coil and Sheet Steel

Cold Rolled Steel Coil and Sheet Steel

-

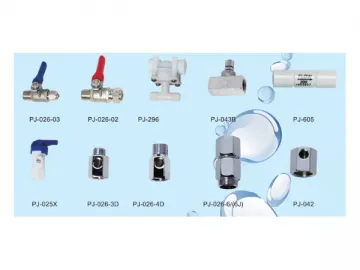

Fittings

Fittings

-

Other Small Parts

Other Small Parts

-

Pre Coated Steel Coil and Sheet Steel

Pre Coated Steel Coil and Sheet Steel

-

Electrical Steel Coil and Sheet Steel

Electrical Steel Coil and Sheet Steel