Ore Feeding Machine

Ore Feeding Machine

The orefeeding machine is also called an electromagnetic vibration feeder. It isdesigned to uniformly, continuously and quantificationally feed agglomerated, granule or powder materials in a storage hopper to receivingequipment such as belt conveyor, bucket elevator, mineral screening equipment,stone crushers, and so on.

The ore feeding machine is designed with half-wave rectifying circuit, so it isable to achieve stepless feeding quantity adjustment. This allows it to be used in automatic productionlines for automatic material feeding, and also make it ideal for use inautomatic material dosing, quantitative packaging industry, and other occasionsrequiring high feeding precision. Now, our ore feeding machine is regularlyused in mining, metallurgy, coal, building material, chemical, power generationand related industries.

We can offer ore feedingmachines in open type and closed type for customers to choose from. With simplestructure and without rotary parts, it is easy for operation, energy saving andrequires no lubrication as well. The trough of the feeding equipment is made ofalloy steel plate, making it applicable for high temperature, abrasive andcorrosive materials. As a kind of vibration feeder, it allows materials to moveforward in micro-parabolic curve, which results in small abrasion to thetrough.

Technical Specifications of the OreFeeding Machine

| Model | Max. feeding size (mm) | Double-amplitude (mm) | Power supply voltage (V) | Power (Kw ) | Feeding capacity (t/h) | Weight (kg) |

| GZ1 | 50 | 1.75 | 220 | 0.06 | 5 | 75 |

| GZ2 | 50 | 1.75 | 220 | 0.15 | 10 | 146 |

| GZ3 | 75 | 1.75 | 220 | 0.2 | 25 | 217 |

| GZ4 | 100 | 1.75 | 220 | 0.45 | 50 | 412 |

| GZ5 | 150 | 1.75 | 220 | 0.65 | 100 | 656 |

| GZ6 | 200 | 1.5 | 380 | 1.5 | 150 | 1252 |

| GZ7 | 250 | 1.5 | 380 | 3 | 250 | 1920 |

| GZ8 | 300 | 1.5 | 380 | 4 | 400 | 3040 |

In order to ensure the service life and reliable performance of the ore feedingmachine, the storage hopper’s effective outlet size should be no more than 1/4of the trough width, the whole production line should be scientificallyconfigured to minimize the materials’ impact on the trough, and materialfeeding speed should be between 6m/min and18m/min.

If large quantity of materials are to be discharged from material storageequipment, there should be a side protective panel with a certain height at thebottom of the discharging hole to prevent materials scattering. Meanwhile, theprotective panel cannot be mounted on the trough of the ore feeding machine. Orelse, the feeder’s performance may be influenced. In order to assure smoothmaterial discharging, the rear wall of material storage hopper is recommendedto be designed with an inclination angle between 55° and 65°.

The ore feeding machine is mainly composed of two parts. One part includesmachine housing, iron core and coil, etc., and the other part includes hitchyoke, armature and trough, etc. The two parts are connected using a bunch ofspring, forming a directional elastic system.

Note:

The orefeeding machine is not designed for use in places with anti-explosionrequirement. As a professional electromagnetic vibration feeder and mineralprocessing machinery manufacturer in China, we can help clients todesign the ore dressing procedure free of charge, and can also help clients todesign mineral processing lines with ore beneficiation capacity from 50 to 2000ton/day.

Working Principle of the Ore Feeding Machine

The ore feeding machine or electromagnetic vibration feeder isequipped with a silicon controlled rectifier. The single phase AC power passesthrough the SCR, and then is supplied to the electric coil. In the positivehalf cycle of the AC power, the SCR is triggered and the pulsating currentpasses through the coil. Thus, the coil generates electromagnetic force toattract the armature, thus making the trough move backward. While in thenegative half cycle of the AC power, the SCR is turned off and there is nocurrent passing through the coil. So, the electromagnetic force is disappeared,and the iron core and armature is separated. Thus, the trough of the orefeeding machine moves forward due to the elastic force from the spring plate.In this way, the trough moves forward and backward alternatively andcontinuously, according to the frequency of the AC power.

As there is a 20° angle between the trough bottom and the line of action ofvibration force, when the ore feeding machine starts, the materials in thetrough moves forward in parabolic motion. Under rated voltage and rated currentconditions, the trough vibration amplitude is about 2ram, which allows thematerials in the trough to move forward continuously and uniformly.

This is how the electromagnetic vibration feeding equipment works.

Links:https://globefindpro.com/products/90870.html

-

Cold Rolled Steel Sheet

Cold Rolled Steel Sheet

-

100GPD Booster Pump

100GPD Booster Pump

-

RO-I-12000 RO Equipment Water System

RO-I-12000 RO Equipment Water System

-

RO-I-24000 Industrial RO Water System

RO-I-24000 Industrial RO Water System

-

Stainless Steel Coil and Sheet Steel

Stainless Steel Coil and Sheet Steel

-

400GPD SB Water Purifier

400GPD SB Water Purifier

-

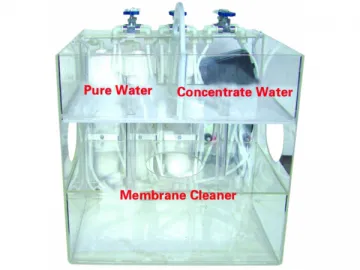

RO Membrane Cleaner

RO Membrane Cleaner

-

Wet Magnetic Separator

Wet Magnetic Separator

-

Filter Cartridge

Filter Cartridge

-

Cold Rolled Steel Coil and Sheet Steel

Cold Rolled Steel Coil and Sheet Steel

-

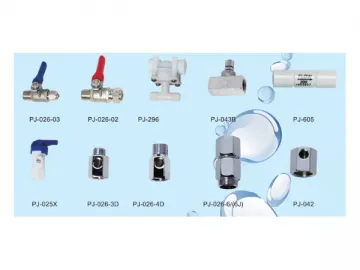

Fittings

Fittings

-

Other Small Parts

Other Small Parts