Seamless Steel Pipe & Hydraulic Hose Assembly

The bent seamless steel pipe body is provided with a plurality of clamp components, each consisting of two U-shaped clamps for holding pipes. The two U-shaped package pipe clamps are clamped and fixed on the pipe body of the bent pipe through bolts and nuts. And two adjacent package pipe clamp components are connected and set through a connecting rod that can support the bent pipe when the pipe body is extruded from the outside. Under the condition that the bent pipe is tensioned, the connecting rod increases the tensile property of the bent pipe due to its positioning function. The connecting rod makes the bent pipe more tensile and compressive, ensuring the accurate connection of the hydraulic seamless steel pipe.

The rubber hydraulic hoses are usually made of 4 layers: a liquid-resistant inner rubber layer that bears pressure for the medium and protects the steel wire from being eroded; a middle rubber layer; 2, 4, or 6 layers of steel wire as a framework material of reinforcement; and an exterior rubber layer protects the steel wire from being damaged.

Types High-pressure hose: steel wire braided hose, steel stripwound hose Industrial hose: air hose, oil suction hose, drain hose, nylon hose, fiber/steel wire braided resin hose, high temperature steam hose Special hose: Teflon hose (PTFE hose), ultra-high pressure hose, jack hose, stainless steel metal bellows ApplicationsLinks:https://globefindpro.com/products/928.html

-

Forced Convection Drying Oven

Forced Convection Drying Oven

-

Vehicle Salt Spray Test Chamber

Vehicle Salt Spray Test Chamber

-

Countertop RO Instant Hot Water Dispenser System

Countertop RO Instant Hot Water Dispenser System

-

UV Aging Test Chamber

UV Aging Test Chamber

-

VOC Accelerated Evaporation Chamber

VOC Accelerated Evaporation Chamber

-

Micro Sampling Chamber

Micro Sampling Chamber

-

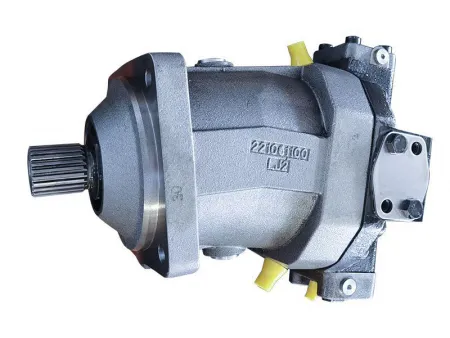

K6VM (Replacement for A6VM Series 63&65&71) Replacement hydraulic motor for A6VM series 63&65&71 axial piston variable motor

K6VM (Replacement for A6VM Series 63&65&71) Replacement hydraulic motor for A6VM series 63&65&71 axial piston variable motor

-

K4FM (Replacement for A4FM) Replacement hydraulic motor for A4FM axial piston fixed motor

K4FM (Replacement for A4FM) Replacement hydraulic motor for A4FM axial piston fixed motor

-

High Pressure Vane Pump with Lower Noise, PV2R Series

High Pressure Vane Pump with Lower Noise, PV2R Series

-

K7VO K7VO (Replacement for A7VO Series 63) Replacement hydraulic pump for A7VO series 63 axial piston variable pump

K7VO K7VO (Replacement for A7VO Series 63) Replacement hydraulic pump for A7VO series 63 axial piston variable pump

-

Hydraulic Vane Pump, SQP Series

Hydraulic Vane Pump, SQP Series

-

K4VSO (Replacement for A4VSO) Replacement hydraulic pump for A4VSO axial piston variable pump

K4VSO (Replacement for A4VSO) Replacement hydraulic pump for A4VSO axial piston variable pump