Vehicle Salt Spray Test Chamber

Vehicle salt spray test chamber is suitable for the salt spray corrosion tests of protection layer of components and parts, electronic hardware components, metal materials and industrial products.

This test chamber typically find application in automotive industry such as salt spray corrosion test of car body, chassis and engine. It can handle neutral salt spray test, acetate spray test and copper accelerated acetate salt spray test.

1.Salt spray

| Average relative velocity of air to test sample | 20-60m/min |

| Salt spray settlement amount | 1-2 (ml/80cm2..h) |

| NaCl solution concentration | 5±0.5% |

| Neutral salt spray test (NSS) collection liquid PH value | (6.5-7.2) |

| Acetate spray test (AASS) collection liquid PH value | (3.0-3.3) |

| The copper accelerated acetic acid salt spray test (CASS) collection liquid PH value | (3.0-3.3) |

| The angle of baffle and vertical direction | 15±2 |

| Number of sprayers | 8 (Ensure even distribution of salt spray) including 2 on bottom |

| Spray method | Air spray, continuous or interval |

| Saturator heating rate | Room Temp. ~ 37℃, ≤ 30 min |

| Salt water tank heating rate | Room Temp.~ 35℃, ≤30 min |

| Temp. range | 20 ° C -80℃ |

| Temp. range | 20℃~ 50℃ |

| Temp. deviation | ±2.0℃ (no-load test) |

| Temp. uniformity | 2.0℃ |

| Temp. fluctuation | ±0.5℃ |

| Empty chamber: | from 25℃ to 50℃≤30min, averagely |

| Humidity range | 85~100%R.H |

| Humidity deviation | ±5% R.H (no-load test) |

| Humidity uniformity | 5% R.H (no-load test) |

| Humidity fluctuation | ±2.5% R.H |

| Noise | 5m from equipment |

Scan QR to Read

Links:https://globefindpro.com/products/930.html

Links:https://globefindpro.com/products/930.html

Recommended Products

-

Countertop RO Instant Hot Water Dispenser System

Countertop RO Instant Hot Water Dispenser System

-

UV Aging Test Chamber

UV Aging Test Chamber

-

VOC Accelerated Evaporation Chamber

VOC Accelerated Evaporation Chamber

-

Micro Sampling Chamber

Micro Sampling Chamber

-

Energy Saving VOC Emission Chamber

Energy Saving VOC Emission Chamber

-

Low Temperature Incubator

Low Temperature Incubator

-

Forced Convection Drying Oven

Forced Convection Drying Oven

-

Seamless Steel Pipe & Hydraulic Hose Assembly

Seamless Steel Pipe & Hydraulic Hose Assembly

-

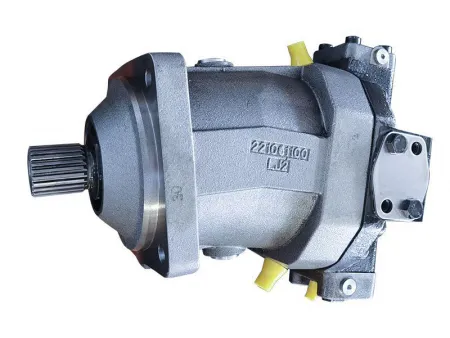

K6VM (Replacement for A6VM Series 63&65&71) Replacement hydraulic motor for A6VM series 63&65&71 axial piston variable motor

K6VM (Replacement for A6VM Series 63&65&71) Replacement hydraulic motor for A6VM series 63&65&71 axial piston variable motor

-

K4FM (Replacement for A4FM) Replacement hydraulic motor for A4FM axial piston fixed motor

K4FM (Replacement for A4FM) Replacement hydraulic motor for A4FM axial piston fixed motor

-

High Pressure Vane Pump with Lower Noise, PV2R Series

High Pressure Vane Pump with Lower Noise, PV2R Series

-

K7VO K7VO (Replacement for A7VO Series 63) Replacement hydraulic pump for A7VO series 63 axial piston variable pump

K7VO K7VO (Replacement for A7VO Series 63) Replacement hydraulic pump for A7VO series 63 axial piston variable pump

Hot Products