DC TIG Welder (Digitally Controlled, Pulse Welding), WSM Series

Features Advanced IGBT inverter technology; Able to accomplish DC manual arc welding, DC argon arc welding and DC pulsed argon arc welding; Suitable for welding of various metals including carbon steel, alloy steel, stainless steel, copper, silver, titanium, etc.; With functions of pre-flow and post-flow gas control, slope up and slope down control, continuous adjusting of parameters; Adjustable pulse frequency, pulse ratio and pulse amplitude; Standard Configurations Earth clamp 1pc Quick connector 2pcs Earth cable 2m Argon arc welding torch 1pc Hex key 1pc Technical Parameters

| Base metal | Thickness (mm) | Process | Welder model | Current adjustment (A) |

| Carbon steel, stainless steel, low-alloy steel | 0.3-5.0 | DC TIG | WSM-200 | 5~200 |

| 0.3-8.0 | DC TIG | WSM-315 | 5~315 | |

| 0.3-12 | DC TIG | WSM-400 | 5~400 | |

| 0.3-14 | DC TIG | WSM-500 | 5~500 | |

| Pure copper /copper | 0.5-4.0 | DC TIG | WSM-315 | 5~315 |

| 0.5-5.0 | DC TIG | WSM-400 | 5~400 | |

| 0.5-6.0 | DC TIG | WSM-500 | 5~500 |

| Model | WSM-200 (TIG-200P) | WSM-315* (TIG-315P) | WSM-400* (TIG-400P) | WSM-500* (TIG-500P) |

| Rated input voltage (V) | 1 phase AC220 ±15% | 3 phase 380V ±15% | ||

| Rated frequency (Hz) | 50/60 | 50/560 | 50/60 | 50/60 |

| Rated input current (A) | 32 | 20 | 27 | 38 |

| Rated input capacity (KVA) | 7 | 13 | 18 | 25 |

| Duty cycle (%) | 8-90 | 8-90 | 8-90 | 8-90 |

| Welding current range (A) | 10~200 | 5~315 | 5~400 | 5~500 |

| Rated frequency range(Hz) | 0.2~20 | 0.2~20 | 0.2~20 | 0.2~20 |

| Power factor | 0.93 | 0.95 | 0.95 | 0.95 |

| Net weight (kg) | 8.5 | 42 | 43 | 50 |

| Dimension (mm) | 370×160×200 | 645×323×573 | 645×323×573 | 645×323×573 |

Scan QR to Read

Links:https://globefindpro.com/products/9354.html

Links:https://globefindpro.com/products/9354.html

Recommended Products

-

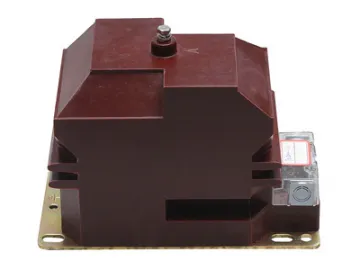

Medium Voltage Current Transformer, LZZBJ9-36-250W1G1

Medium Voltage Current Transformer, LZZBJ9-36-250W1G1

-

Outdoor Vacuum Circuit Breaker, ZW43-12/24F

Outdoor Vacuum Circuit Breaker, ZW43-12/24F

-

Medium Voltage Indoor Current Transformer, LZZBJ9-12

Medium Voltage Indoor Current Transformer, LZZBJ9-12

-

40.5KV Outdoor Vacuum Circuit Breaker, ZW7-40.5

40.5KV Outdoor Vacuum Circuit Breaker, ZW7-40.5

-

Vacuum Contactor, CKJ5-125/250/400/600

Vacuum Contactor, CKJ5-125/250/400/600

-

Outdoor Vacuum Circuit Breaker with Permanent Magnetic Mechanism, ZW32-12M

Outdoor Vacuum Circuit Breaker with Permanent Magnetic Mechanism, ZW32-12M

-

Medium Voltage Outdoor Voltage Transformer, JDZX10-10

Medium Voltage Outdoor Voltage Transformer, JDZX10-10

-

12/24kV Indoor Vacuum Circuit Breaker, ZN63A(VS1)-12C

12/24kV Indoor Vacuum Circuit Breaker, ZN63A(VS1)-12C

-

6-10kV Ring Main Unit, HXGN口- 12

6-10kV Ring Main Unit, HXGN口- 12

-

Low-voltage Switchgear (AC Power), AGGD Series

Low-voltage Switchgear (AC Power), AGGD Series

-

Indoor Vacuum Contactor, JCZ5

Indoor Vacuum Contactor, JCZ5

-

40.5kV Medium-voltage Metal-clad Switchgear, KYN61

40.5kV Medium-voltage Metal-clad Switchgear, KYN61

Hot Products