Multi-Effect Plate Evaporator

Multi-Effect Plate Evaporator

Features

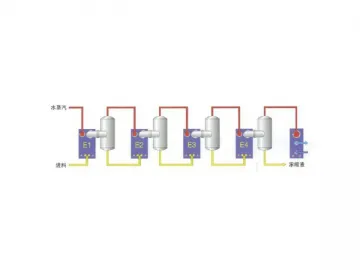

Themulti-effect plate evaporator uses special-made plates, variable cross sectionchannel which can evidently cause turbulence to decrease heat resistance ofliquid film. Due to the control of material and steam flow, films are formed onboth sides of the plates, which raises convective heat-transfer coefficient.Plates are made of slim sheet, which decrease the heat resistance. The accumulatorand steam brush are not easy to dirt. The total heat transmission coefficientis 3-5 times that of the tube evaporator. It not only has high efficiency ofevaporation and condensation, but also decreases the size of the heatinterchanging area. The heat interchanging area on average is twice that of thetube evaporator in same cubage.

The multi-effect plateevaporator can combine several processes together according to thecharacteristics of the material. It has features of compact structure, highevaporation power, high density of liquid, low consumption of electricity andgas, continuous operation and easy expansion. This evaporator issuitable for continuous evaporation and condensation of dairy products,beverage, pharmacy, starch, sugar, alcohol, chemical industry, and is alsoapplicable to separate mother liquid in alumina industry.

Specifications of Multi-Effect PlateEvaporator

| Model | Evaporation Capacity (t/h) | Steam Consumption (Generated vapor) (t/h) | Steam Pressure (Mpa ) | Solid content on inlet (%) | Solid content on outlet (%) | ||

| JMZ3.0 | 3.0 | 0.9 | 0.85 (Absolute pressure | 4~5 (alcohol mash) | 6~7 (corn steep liquor) | 30~35 (alcohol mash) | 42~48 (corn steep liquor) |

| JMZ6.0 | 6.0 | 1.8 | |||||

| JMZ12.0 | 12.0 | 3.6 | |||||

| JMZ20.0 | 20.0 | 6.0 | |||||

| JMZ30.0 | 30.0 | 9.0 | |||||

| JMZ50.0 | 50.0 | 15.0 | |||||

| JMZ60.0 | 60.0 | 18.0 | |||||

| JMZ70.0 | 70.0 | 21.0 | |||||

| JMZ80.0 | 80.0 | 24.0 | |||||

| JMZ100.0 | 100.0 | 30.0 | |||||

| Model | Evaporation Capacity (t/h) | Steam Consumption (wasted heat utilized) (t/h) |

| F JMZ3.0 | 3.0 | 0.9 |

| F JMZ6.0 | 6.0 | 1.8 |

| F JMZ12.0 | 12.0 | 3.6 |

| F JMZ20.0 | 20.0 | 6.0 |

| F JMZ30.0 | 30.0 | 9.0 |

| F JMZ50.0 | 50.0 | 15.0 |

| F JMZ60.0 | 60.0 | 18.0 |

| F JMZ70.0 | 70.0 | 21.0 |

| F JMZ80.0 | 80.0 | 24.0 |

| F JMZ100.0 | 100.0 | 30.0 |

| Model | Evaporation Capacity (t/h) | Steam Consumption (Generated vapor) (t/h) | Steam Pressure (Mpa ) | Solid content on inlet (%) | Solid content on outlet (%) | ||

| JMZ3.0 | 3 | 0.9 | 0.85 (Absolute pressure | 4~5 (alcohol mash) | 6~7 (corn steep liquor) | 30~35 (alcohol mash) | 42~48 (corn steep liquor) |

| JMZ6.0 | 6 | 1.8 | |||||

| JMZ12.0 | 12 | 3.6 | |||||

| JMZ20.0 | 20 | 6 | |||||

| JMZ30.0 | 30 | 9 | |||||

| JMZ50.0 | 50 | 15 | |||||

| JMZ60.0 | 60 | 18 | |||||

| JMZ70.0 | 70 | 21 | |||||

| JMZ80.0 | 80 | 24 | |||||

| JMZ100.0 | 100 | 30 | |||||

| F JMZ3.0 | 3 | 0.9(wasted heat) | |||||

| F JMZ6.0 | 6 | 1.8(wasted heat) | |||||

| F JMZ12.0 | 12 | 3.6(wasted heat) | |||||

| F JMZ20.0 | 20 | 6(wasted heat) | |||||

| F JMZ30.0 | 30 | 9(wasted heat) | |||||

| F JMZ50.0 | 50 | 15(wasted heat) | |||||

| F JMZ60.0 | 60 | 18(wasted heat) | |||||

| F JMZ70.0 | 70 | 21(wasted heat) | |||||

| F JMZ80.0 | 80 | 24(wasted heat) | |||||

| F JMZ100.0 | 100 | 30(wasted heat) | |||||

Links:https://globefindpro.com/products/93593.html