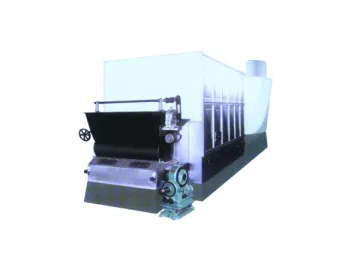

Revolving Flash Vaporization Dryer

Revolving Flash Vaporization Dryer

Working Principle

The materials that need drying enterthe revolving flash vaporization dryer through the spiral feeder. Under thestrong action of high speed revolving mixer, the materials are crushed and dispersedby the effect of friction. The crushed materials then fully contact with the hotair, and get dried.

The powder materials after dewatering rise with the hot air, and then classifiedby the annular classifier. Big pellets are retained, while small pellets aredischarged from the drier through the center of annular classifier, andrecycled by cyclone separator. Chunk material and material which is notthoroughly dried are rotated to the wall of revolving flash vaporization dryerand fall down to the bottom to be crushed and dried again.

Specifications of Revolving Flash Vaporization Dryer

| Model | Cylinder dia (mm) | Main Body Size(mm) | Main Body Power(KW) | Volume of Air (m³/h) | Water Evaporation (kg/h) | Covering Area(mm²) |

| XSG-2 | 200 | 250*2800 | 0.75-2.2 | 300-800 | 10-20 | 3500*2500 |

| XSG-3 | 300 | 400*3300 | 3-4 | 600-1500 | 25-50 | 3800*2700 |

| XSG-4 | 400 | 500*3500 | 4-7.5 | 1250-2500 | 25-70 | 4000*3000 |

| XSG-5 | 500 | 600*4000 | 5.5-11 | 1500-4000 | 30-100 | 4200*3200 |

| XSG-6 | 600 | 700*4200 | 7.5-18.5 | 2500-5000 | 40-200 | 4250*3250 |

| XSG-8 | 800 | 900*4600 | 11-18.5 | 3000-8000 | 60-600 | 4500*3500 |

| XSG-10 | 1000 | 1100*5000 | 15-30 | 5000-12500 | 100-1000 | 4750*3750 |

| XSG-12 | 1200 | 1300*5200 | 15-37 | 10000-20000 | 150-1300 | 5000*4000 |

| XSG-14 | 1400 | 1500*5400 | 30-55 | 14000-27000 | 200-1600 | 5250*4250 |

| XSG-16 | 1600 | 1700*6000 | 45-75 | 18700-36000 | 250-2000 | 5500*4500 |

Links:https://globefindpro.com/products/93595.html