ABS Vacuum Forming

ABS Vacuum Forming

For vacuum forming,appropriate materials shall be chosen in line with performance, serviceenvironment and grades of the products. The commonly-used materials are ABS,HIPS, PC, PETG, PMMA, HDPE, ABS or PC, ABS or PMMA, ASA, ABS orASA, PO, PPO, PVC, GAG, PET and more.

Keeping productperformance and material cost in mind, we can always choose the appropriate ABSmaterials for producing ABS vacuum forming products, whether general type orextrusion type, high luster type or matte type, common type or patterned type,flame resistant type, heat resistant type or food grade type, and more. ABSmaterials for both indoor use and outdoor use which are UV resistant are alsoavailable.

ABS vacuum forming is widely used in covers of various products, includingmedical products, machinery, electronic products, military products, toys,automobile parts, displays and more.

ABS vacuum forming is superior to injection molding and other techniques. Itfeatures fast die sinking, with an average period of 6 to 25 days. In addition,the mold cost is relatively low and the products are not restricted to sizes.Typically, the length can be over 10 meters, the width can reach 6 meters andthe height can reach 1.2 meters.

Links:https://globefindpro.com/products/94287.html

-

High Power LED Light

High Power LED Light

-

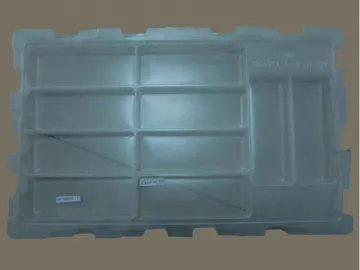

Blister Tray

Blister Tray

-

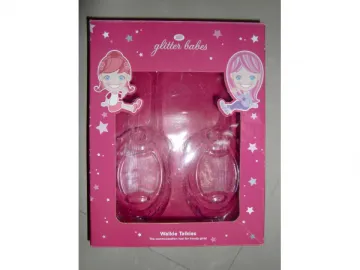

Electronic Blister Pack

Electronic Blister Pack

-

SMD LED Strip Light

SMD LED Strip Light

-

LED Motif Light

LED Motif Light

-

Plastic Luggage Vacuum Forming Cover

Plastic Luggage Vacuum Forming Cover

-

T5 6U/8U Energy Saving Bulb

T5 6U/8U Energy Saving Bulb

-

Flexible LED Rope Light

Flexible LED Rope Light

-

Fluorescent Grille Light

Fluorescent Grille Light

-

T5 68*58mm Fluorescent Tube Light

T5 68*58mm Fluorescent Tube Light

-

T3 Energy Saving Light Bulb

T3 Energy Saving Light Bulb

-

Vacuum Forming Plastic Machine Casing

Vacuum Forming Plastic Machine Casing