Vertical Form Fill Seal Machine with Vibratory Bowl Feeder, SK-L3B320-ZP

Features

Bag forming, material measuring and filling, bag sealing and cutting are all completed in one linear process.

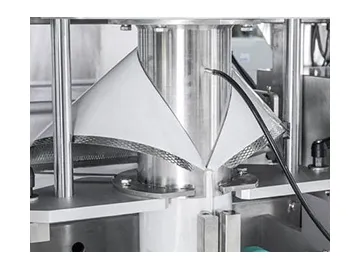

Unique packaging sealing technology improves the seal aesthetics and fastness.

Multiple vibrating disks are used to place different materials into one bag. One, two, three or mor vibrating disk configurations are optional depending on the customer's individual requirements.

Application

The VFFS machine with a vibratory bowel feeder is suitable for packaging various hardware fittings, including:

Hardware: screw, nut, gasket

Plastic parts: expansion pipe, rubber ring

Furniture parts: self-tapping screw, fastener, stamping parts

Other components: bathroom hardware accessories, electronic parts, bike parts and more

Technical Parameters

Packaging materials samples

Bag forming, material measuring and filling, bag sealing and cutting are all completed in one linear process.

Unique packaging sealing technology improves the seal aesthetics and fastness.

Multiple vibrating disks are used to place different materials into one bag. One, two, three or mor vibrating disk configurations are optional depending on the customer's individual requirements.

Application

The VFFS machine with a vibratory bowel feeder is suitable for packaging various hardware fittings, including:

Hardware: screw, nut, gasket

Plastic parts: expansion pipe, rubber ring

Furniture parts: self-tapping screw, fastener, stamping parts

Other components: bathroom hardware accessories, electronic parts, bike parts and more

Technical Parameters

| Model | SK-L3B320-ZP |

| Film width | Max.320mm |

| Bag length | 50-200mm |

| Bag width | 30-150mm |

| Measurement range | 30-150ml |

| Packaging speed | 5-50bags/min (depending on the materials, film and quantity of materials to be filled in each bag) |

| Film roll outer diameter | Max.360mm |

| Power | 220V.50Hz/60Hz,2.8kw |

| Measurement method | weighing |

| Packaging | OPP/CPP.OPP/CE.MST/PE/PET/PE |

| Bag format | pillow bag or 3-side seal bag |

If you are interested in our VFFS machine with vibratory bowel feeder, feel free to contact us for more details.

Scan QR to Read

Links:https://globefindpro.com/products/9481.html

Links:https://globefindpro.com/products/9481.html

Recommended Products

-

Auger Filler VFFS Machine

Auger Filler VFFS Machine

-

Vertical Form Fill Seal Machine with Linear Weigher, L320QD-D4T

Vertical Form Fill Seal Machine with Linear Weigher, L320QD-D4T

-

Fully Automatic Vertical Form Fill Seal Machine with Linear Weigher, SK-L420/520/620/720/820

Fully Automatic Vertical Form Fill Seal Machine with Linear Weigher, SK-L420/520/620/720/820

-

Vertical Form Fill Seal Machine with Volumetric Cup Filler, SK-L360-A

Vertical Form Fill Seal Machine with Volumetric Cup Filler, SK-L360-A

-

Vertical Form Fill Seal Machine with Auger Filler, L420/520/620/720/820FT

Vertical Form Fill Seal Machine with Auger Filler, L420/520/620/720/820FT

-

Weighing Filling Machine

Weighing Filling Machine

-

Vertical Form Fill Seal Machine with Multihead Weigher, SK-L420/520/620/720/820-D14

Vertical Form Fill Seal Machine with Multihead Weigher, SK-L420/520/620/720/820-D14

-

Fully Automatic Vertical Form Fill Seal Machine with Multihead Weigher

Fully Automatic Vertical Form Fill Seal Machine with Multihead Weigher

-

Vertical Form Fill Seal Machine with Auger Filler, L4T620-FT

Vertical Form Fill Seal Machine with Auger Filler, L4T620-FT

-

Vertical Form Fill Seal Machine with Volumetric Cup Filler, SK-L380DL-AT

Vertical Form Fill Seal Machine with Volumetric Cup Filler, SK-L380DL-AT

-

Vertical Form Fill Seal Machine with Piston Filler, Y Type

Vertical Form Fill Seal Machine with Piston Filler, Y Type

-

Vertical Form Fill Seal Machine with Auger Filler, B320QD-F

Vertical Form Fill Seal Machine with Auger Filler, B320QD-F

Hot Products