Low Speed Granulator

Features Application. The low speed granulator is designed for granulating degraded materials or rejected parts made of PC/Nylon/PP/ABSS. Time and cost saving: wasted parts can be recycled within 20 seconds with no need for waiting for centralized crushing, thus reducing labor, management and storage costs. Easy to detach, clean and maintain. The granulator features an easy material changeover and fast cleaning, making it suitable for working with the injection molding machine. Environmentally friendly and energy saving: The granulator delivers consistent granule sizes (3-8mm), minimizes dust and reduces noise level (80-95db). A time relay is equipped to reduce power consumption. Superior blades: high strength steel SKD-11 blades feature an excellent fineness, excellent toughness and excellent high temperature resistance. Motor overload protection and power interlock protection functions are designed to improve operation safety. Technical specifications

| Model | YKMS-1.5HP | YKMS-2HP | YKMS-3HP | YKMS-3HP-G | YKMS-5HP | |

| Cutting chamber size(mm) | 250x300 | 320x320 | 320*430 | 400x356 | 406x516 | |

| Granulation capacity(kg/h) | 15-20 | 35-45 | 50-60 | 60-80 | 80-100 | |

| Rotor speed | 23 | |||||

| Motor power (HP) | 1 | 2 | 3 | 3 | 5 | |

| Machine power (KW) | 1.1 | 1.5 | 2.2 | 2.2 | 3.7 | |

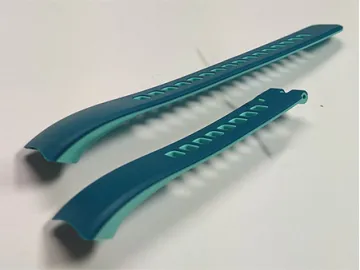

| Blade type | Hook Blade | |||||

| Number of rotor blades (PCS) | rotating blade*2 hob*3 | rotating blade*2 hob*3 | rotating blade*3 hob*4 | rotating blade*3 hob*4 | rotating blade*3 hob*4 | |

| Number of fixed blades (PCS) | 6 | 6 | 8 | 8 | 8 | |

| Blade material | SKD-11 | SKD-11 | SKD-11 | SKD-11 | SKD-11 | |

| Noise level(dB) | 70-75 (don't include background sound) | |||||

| Plastic feeding method | Feed hopper/material suction loader/material blower feeder | |||||

| Dimensions (L*W*H) (mm) | 910*320*1120mm | 1090*430*1220mm | 1090*430*1260mm | 1090*430*1260mm | 1240*610*1580mm | |

| Weight (Kg) | 150 | 200 | 260 | 280 | 500 | |

Scan QR to Read

Links:https://globefindpro.com/products/9571.html

Links:https://globefindpro.com/products/9571.html

Recommended Products

-

TMS-001 Hot Runner Sequential Controller

TMS-001 Hot Runner Sequential Controller

-

Sheet

Sheet

-

Mold Temperature Controller, YK-D-15A Series

Mold Temperature Controller, YK-D-15A Series

-

Hydraulic Power Units

Hydraulic Power Units

-

Benefits of LSR Overmolding

Benefits of LSR Overmolding

-

Pipe Fittings

Pipe Fittings

-

Silicone Rubber Compression Molding

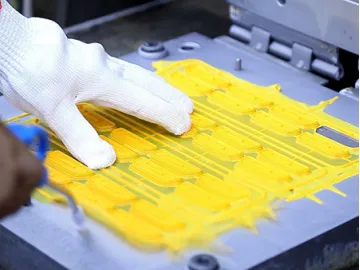

Silicone Rubber Compression Molding

-

Round Bar

Round Bar

-

Water Cooled Temperature Control Unit

Water Cooled Temperature Control Unit

-

Linear Module, Series KTH6

Linear Module, Series KTH6

-

Linear Guide, Roller Type Linear Motion Guide

Linear Guide, Roller Type Linear Motion Guide

-

Gantry System, 2 Axis XX'-YY'

Gantry System, 2 Axis XX'-YY'

Hot Products