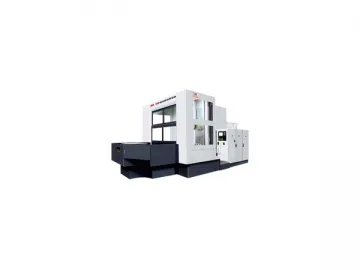

Vertical Machining Center VMC650E, VMC850E

The spindle of vertical machining center is equipped with positioning feedback, enabling high-speed right tapping. The headstock is counterbalanced mechanically, with smooth and flexible operation. The design of the basic components such as bed, column, and others incorporate thermal symmetry and box-style rib plates. Resin bonded sand casting ensures exceptionally stable accuracy. The fully enclosed work area and mechanical-electrical integration are well engineered, environmentally focused, convenient for operation, maintenance- friendly, and attractive in appearance. The design of this series of machine structures ensures high rigidity and reliable accuracy. Motors of this vertical machining center are directly connected to ball-screws, which ensures high speed capability. The spindle adopts precision angular contact ball bearings for high speed and accuracy. Spindle speeds up to 8000 rpm. Rapid feed: 32 m/min in X and Y, and 30 m/min in Z. The operator interface is user-friendly.

Standard Accessories

Umbrella tool magazine

Cooling system

Water tank

Chip blower

CNC SYSTEM: FANUC 0i

Pneumatic system

Lighting system

3-color alarm lamp

Adjustable iron pad, fixed bolt cool-heat exchanger

Cleaning system of spindle counterbore

Auto lubricating system

Full Workspace Enclosure Stainless steel guideway covers.

Stainless protective drawplate

Optional accessories

24 tool arm-type tool magazine

Air conditioner

4th axis rotary table

Coolant through spindle

Features

Driving mode with high speed and high accurcy

The spindle is directly coupled to the spindle motor, which improves start speed and ensures driving efficiency.

The umbrella-type tool magazine with 16 tools can satisfy the customers’ requirement on machining efficiency

Spindle with high accuracy

The belt-type coupling spindle is reliable and practical, effectively increasing driving torque.

Standard spindle is BT40 with 8000 RPM

Chip Conveyor

The bed adopts integrated structure, a spiral chip conveyor is located at the fore of the bed, easy and rapid for chips removing; a water outlet is located at the rear of the bed, ensuring no leaking.

Specifications of Vertical Machining Center VMC650E, VMC850E

| Item Unit | VMC650E | VMC850E | |||

| Worktable | Worktable dimensions | mm | 900×420 | 1000×500 | |

| Max. load allowed | kg | 600 | 600 | ||

| T-slot sizes | mm×N | 18×3 | 18×5 | ||

| Machining range | Max. travel of worktable- X axis | mm | 650 | 850 | |

| Max. travel of slider - Y axis | mm | 400 | 500 | ||

| Max. travel of spindle - Z axis | mm | 500 | 540 | ||

| Distance from spindle nose to worktable | mm | 130-630 | 150-690 | ||

| Spindle | Taper bore (7:24) | BT40 | BT40 | ||

| Speed range | r/min | 50-8000 | 50-8000 | ||

| Max. output torque | Nm | 35.8 | 35.8 | ||

| Main motor power | kW | 7.5/11 | 7.5/11 | ||

| Distance from spindle centre to column guideway face | mm | 530 | 580 | ||

| Spindle driving mode | Belt–type drive | Belt–type drive | |||

| Tools | Leaf tool | Pintongs tool of 45° | Pintongs tool of 45° | ||

| Tool-shank specification | MAS403:BT40 | MAS403:BT40 | |||

| Pull stud specification | MAS403:LDA-BT40 | MAS403:LDA-BT40 | |||

| Feed | Feed speed | m/min | 20 | 20 | |

| Rapid speed | X axis | m/min | 32 | 32 | |

| Y axis | m/min | 32 | 32 | ||

| Z axis | m/min | 30 | 30 | ||

| Tool magazine | Tool magazine form | Umbrella type | Umbrella type | ||

| Tool magazine capacity | pcs | 16 | 16 | ||

| Max. tool length | mm | 200 | 250 | ||

| Max. tool weight | kg | 7 | 7 | ||

| Tool change time (tool-to-tool) | s | 7 | 7 | ||

| Diameter of max. tool pan | Full | mm | φ80 | φ80 | |

| Adjacent station empty | mm | φ125 | φ125 | ||

| Positioning accuracy | X/Y/Z axis | JISB6330 | mm | ±0.005/300 | ±0.005/300 |

| JB/T8771.4-1998 | mm | 0.020/0.015/0.015 | 0.020/0.015/0.015 | ||

| Repeatability | X/Y/Z axis | JISB6330 | mm | ±0.003 | ±0.003 |

| JB/T8771.4-1998 | mm | 0.012/0.010/0.010 | 0.012/0.010/0.010 | ||

| Power supply | General power capacity | KVA | 18 | 18 | |

| Air pressure | Mpa | 0.5-0.7 | 0.5-0.7 | ||

| Overall dimension (L×W×H) | mm | 2650×2400×2600 | 3300×2400×3000 | ||

| Machine weight | kg | 5000 | 5800 | ||

| CNC system | FANUC 0i Mate-MD | FANUC 0i Mate-MD | |||

Links:https://globefindpro.com/products/96261.html

-

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

-

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

-

LED Cup Light GU10

LED Cup Light GU10

-

LED Reading Lamp

LED Reading Lamp

-

HMC50, HMC63, HMC80 Horizontal Machining Center

HMC50, HMC63, HMC80 Horizontal Machining Center

-

LED Grow Light

LED Grow Light

-

LED Reading Lamp

LED Reading Lamp

-

Vertical Machining Center, VMC0540d, VMC0745d, VMC0955d

Vertical Machining Center, VMC0540d, VMC0745d, VMC0955d

-

LED Grow Light

LED Grow Light

-

LED Grow Light

LED Grow Light

-

Festoon bulb 44mm x 10mm

Festoon bulb 44mm x 10mm

-

LED String Light

LED String Light