PVDF Aluminum Composite Panel

PVDF Aluminum Composite Panel

PVDF Coating

Fluorocarbon aluminum composite panel is made of a mixture of fluorocarbon resin with fluorine enzyme as the basic monomer, paint, alcohol ester solvent and accessory ingredients. The molecular structure in the coating is compact after being high temperature baked into film formation, which provides the composite panel with extra-strong weather resistance. The fluorocarbon coating falls into conventional fluorocarbon coating. Conventional fluorocarbon is made of KYNAR500 fluorocarbon and is solidified into film formation on the surface after three coats and three bake. The superior quality coating provides the aluminum composite panel with good acid and alkali resistance, and allows the panel to stand the test of severe environment. So, PVDF coated ACP has no abnormal depigment within 15 to 20 years, which is more applicable for exterior decoration of architectures and curtain wall decoration of major constructional projects that have high demand for weather resistance.

Feature

Advantages of PVDF aluminum composite coating include light weight, high strength, extreme rigidity, superior impact resistance, excellent surface flatness and smoothness, heat insulation, sound insulation, fire-resistance, acid-resistance, alkali-resistance, good weatherproofing and non-resonance, various uniform colors, and more. Meanwhile, this construction material can be easily processed, fabricated and quickly installed. It is also elegant and magnificent, and comes with good flexibility, easy maintenance and simple cleaning. It fits various designs.

Application

1) Constructional exterior curtain walls

2) Decorative renovation for storey-added old buildings

3) Advertisement board, shop face decorating, display platforms and signboards

4) Wallboard and ceilings for tunnels; Circular columns for outside use

5) The PVDF aluminum composite panel is also an ideal raw material for industrial purpose

PVDF Aluminum Composite Panel

The PVDF aluminum composite panel consists of two sheets of corrosion resistant aluminum permanently bonded to polyethylene core material. The front aluminum coats PVDF (Fluor resin) paint. Because of its excellent weather proof and other features, this aluminium composite material becomes a very popular cladding material in the world.

Specifications of PVDF Coating Aluminium Composite Panel

| Panel thickness | 3mm,4mm.5mm,6mm |

| Panel width | 1000mm,1220mm,1250mm,1350mm,1500mm,1570mm |

| Panel length | 2440mm-5800mm,or per customer’s request |

| Alu skin thickness | 0.25mm,0.30mm,0.35mm,0.40mm,0.45mm,0.50mm |

| Standard size | 1220(W) ×2440(L)mm |

| paint | polyester coating |

| core | Normal PE core |

PVDF Coating

Fluorocarbon aluminum composite panel is made of a mixture of fluorocarbon resin with fluorine enzyme as the basic monomer, paint, alcohol ester solvent and accessory ingredients. The molecular structure in the coating is compact after being high temperature baked into film formation, which provides the composite panel with extra-strong weather resistance. The fluorocarbon coating falls into conventional fluorocarbon coating. Conventional fluorocarbon is made of KYNAR500 fluorocarbon and is solidified into film formation on the surface after three coats and three bake. The superior quality coating provides the aluminum composite panel with good acid and alkali resistance, and allows the panel to stand the test of severe environment. So, PVDF coated ACP has no abnormal depigment within 15 to 20 years, which is more applicable for exterior decoration of architectures and curtain wall decoration of major constructional projects that have high demand for weather resistance.

Feature

Advantages of PVDF aluminum composite coating include light weight, high strength, extreme rigidity, superior impact resistance, excellent surface flatness and smoothness, heat insulation, sound insulation, fire-resistance, acid-resistance, alkali-resistance, good weatherproofing and non-resonance, various uniform colors, and more. Meanwhile, this construction material can be easily processed, fabricated and quickly installed. It is also elegant and magnificent, and comes with good flexibility, easy maintenance and simple cleaning. It fits various designs.

Application

1) Constructional exterior curtain walls

2) Decorative renovation for storey-added old buildings

3) Advertisement board, shop face decorating, display platforms and signboards

4) Wallboard and ceilings for tunnels; Circular columns for outside use

5) The PVDF aluminum composite panel is also an ideal raw material for industrial purpose

Scan QR to Read

Links:https://globefindpro.com/products/96630.html

Links:https://globefindpro.com/products/96630.html

Recommended Products

-

Advertising CNC Router NC-B1212

Advertising CNC Router NC-B1212

-

Advertising CNC Router NC-B3636

Advertising CNC Router NC-B3636

-

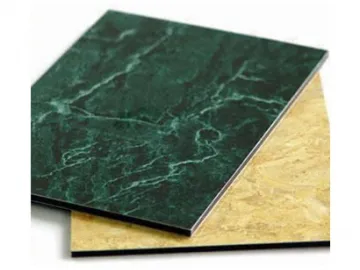

Granite / Wood Aluminium Composite Panel

Granite / Wood Aluminium Composite Panel

-

Solution

Solution

-

Laser Engraving Machine (NC-E4060)

Laser Engraving Machine (NC-E4060)

-

Aluminum Coil (Aluminum Sheet Coil)

Aluminum Coil (Aluminum Sheet Coil)

-

Woodworking CNC Router NC-R1325

Woodworking CNC Router NC-R1325

-

Advertising CNC Router NC-B1318

Advertising CNC Router NC-B1318

-

Desktop CNC Router NC-A6090

Desktop CNC Router NC-A6090

-

Laser Engraving Machine (NC-C6090)

Laser Engraving Machine (NC-C6090)

-

Fireproof Aluminum Composite Panel

Fireproof Aluminum Composite Panel

-

Advertising CNC Router NC-B6090

Advertising CNC Router NC-B6090