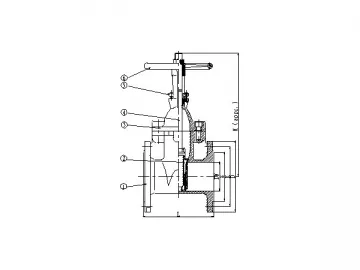

SHC-2H Knife Gate Valve

SHC-2H KnifeGate Valve

Specification of Knife GateValve

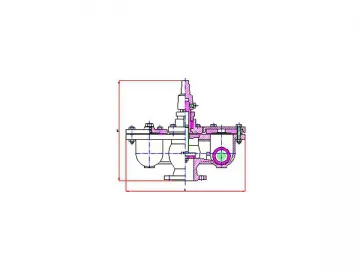

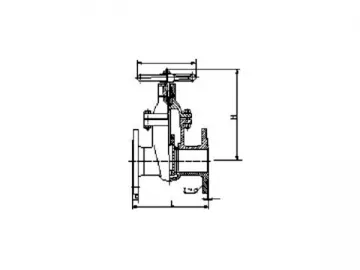

Model No: SHC-2H

Knife gate valve rising stem class 125

One-piece cast iron body,

Bolted bonnet out stem and yoke type

Manufacture and design: factory standards

Flanged end: ASME B16.5,

Industry application: paper, water

Waster water, chemical, power, steel, mining

Available with chain, gear, electric, air or hydrolicactuation. WORKING Temperature: 100C,

Inspection and test: Shell: 300PSI(water),.

Seat: 80PSI(air).

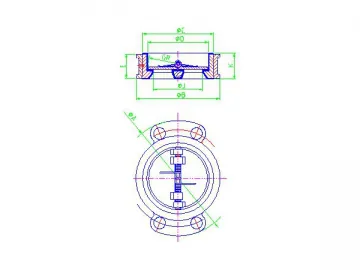

Parts and materials of Knife Gate Valve

| Parts and material | ||

| No. | Parts name | Materials |

| 1 | Body | ASTM A356 |

| 2 | Disc | ASTM SS304/SS316/CARBON STEEL |

| 3 | Gland Packing | PTFE/NBR/CARBIDE ALLOY/S.S. |

| 4 | Gland | ASTM A216-WCB |

| 5 | Bonnet bolt | ASTM A193-B7 |

| 6 | Bonnet nut | ASTM A194-2H |

| 7 | Disc bolt | ASTM A193-B7 |

| 8 | Disc holder | CARBON STEEL |

| 9 | Bonnet | ASTM A126/A356 |

| 10 | Stem nut | BRONZE |

| 11 | Hand wheel | CAST IRON |

| 12 | H.W. lock nut | Ductile iron |

| 13 | Stem | ASTEM SS304/SS316/carbon steel |

| 14 | Seat | NBR/PTFE/S.S/Carbide alloy |

| Other materials are available upon request | ||

Our Butterfly Valve, Gate Valve, GlobeValve, Check Valve, Ball Valve, Knife Gate Valve, Air Valve, Foot Valve,Hydrant Valve, Strainer and Pipe Fittings can exceed customers’ expectation.

SHC-2H KnifeGate Valve

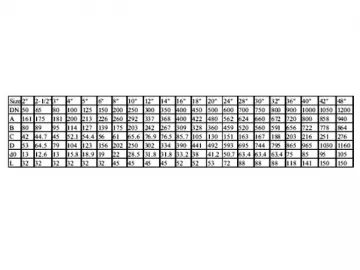

| DIMENSIONS LIST: UNIT: MM | |||||||||

| SIZE | DN | L | D | D1 | D2 | H | b | n- | W |

| 2 | 50 | 55 | 152 | 120.5 | 100 | 302 | 16 | 4-19 | 240 |

| 2-1/2 | 65 | 55 | 178 | 139.5 | 111 | 317 | 18 | 4-19 | 240 |

| 3 | 80 | 55 | 190 | 152.5 | 132 | 340 | 19 | 4-19 | 240 |

| 4" | 100 | 55 | 229 | 190.5 | 170 | 377 | 20 | 8-19 | 280 |

| 5 | 125 | 60 | 254 | 216 | 186 | 430 | 20 | 8-22 | 280 |

| 6" | 150 | 60 | 279 | 241.5 | 218 | 525 | 20 | 8-22 | 360 |

| 8" | 200 | 70 | 343 | 298.5 | 275 | 670 | 22 | 8-22 | 360 |

| 10" | 250 | 80 | 406 | 362 | 335 | 771 | 22 | 12-25 | 400 |

| 12" | 300 | 80 | 483 | 432 | 405 | 895 | 25 | 12-25 | 400 |

| 14" | 350 | 90 | 533 | 476 | 413 | 982 | 25 | 12-29 | 500 |

| 16 | 400 | 100 | 597 | 540 | 484 | 1245 | 28 | 16-29 | 500 |

| 18 | 450 | 120 | 635 | 578 | 534 | 1338 | 28 | 16-32 | 500 |

| 20 | 500 | 120 | 698 | 635 | 584 | 1465 | 30 | 20-32 | 500 |

| 24 | 600 | 130 | 813 | 749.5 | 692 | 1658 | 30 | 20-35 | 720 |

* We herebyreserve the rights of any alternative dimension that would help improve ourvalve's quality and working efficiency.

Links:https://globefindpro.com/products/100432.html