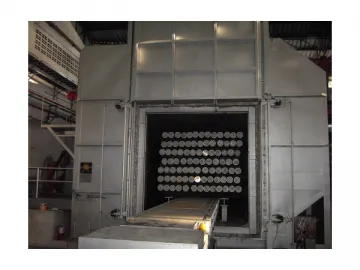

Hot Top Billet Casting Machine

We make aluminium billets casting machine according to customer's detail requirement.

Machine type: there are 2 types, hydraulic type and charger type.

The maximum quantity of billet on the hot top is up to 130 Pcs.

Hot top system use wire rope and hydraulic system which is more convenient comparing with the traditional type.

Hot top table main components include: billet casting mould, , pulling machine, well, etc.

Hot top billet casting machine spare parts like: distributor tray, retain cup, graphite ring, rubber seal, etc.

Hot top aluminium billet casting machine delivery period within 30 days

Local installation is around 6 days by one engineer.

Features

1. The hot top billet casting machine uses a close-packed hot-top casting system, aligns the dummy bar automatically, and is free from silicic acid paper.

2. The casting speed is 0-250 mm/min (stepless speed regulation). There is an assorted anti-speed system with 5-kw traction power.

3. After completion of the casting, the casting table can flip 89° on the plate by stable hydraulic transmission system.

Technical Parameters

| Model No. | Billet Size Dia. × Length (mm) | Billet Qty (pcs) | Power (kw) | Weight per time (kg) | Tilting Angle (°) | Well Size L × W (mm) |

| YG-ZB3.5" | Φ90*6,000 | 54 | 8 | 5,562 | 0-89 | 1,900*1,900 |

| YG-ZB5" | Φ127*6,000 | 32 | 8 | 5,859 | 0-89 | 1,800*1,800 |

| YG-ZB5.5" | Φ140*6,000 | 24 | 8 | 5,982 | 0-89 | 1,800*1,800 |

| YG-ZB6" | Φ152*6,000 | 20 | 8 | 5,876 | 0-89 | 1,600*1,600 |

| YG-ZB7" | Φ178*6,000 | 16 | 8 | 6,446 | 0-89 | 1,600*1,600 |

| YG-ZB8" | Φ203*6,000 | 12 | 8 | 6,288 | 0-89 | 1,600*1,600 |

| YG-ZB9" | Φ230*6,000 | 8 | 8 | 5,382 | 0-89 | 1,600*1,600 |

| YG-ZB3.5" | Φ90*6,000 | 100 | 11 | 10,300 | 0-89 | 2,400*2,400 |

| YG-ZB5" | Φ127*6,000 | 60 | 11 | 10,987 | 0-89 | 2,300*2,300 |

| YG-ZB5.5" | Φ140*6,000 | 42 | 11 | 10,468 | 0-89 | 2,000*2,000 |

| YG-ZB6" | Φ152*6,000 | 36 | 11 | 10,577 | 0-89 | 2,000*2,000 |

| YG-ZB7" | Φ178*6,000 | 26 | 11 | 10,476 | 0-89 | 2,100*2,100 |

| YG-ZB8" | Φ203*6,000 | 20 | 11 | 10,481 | 0-89 | 1,800*1,800 |

| YG-ZB9" | Φ230*6,000 | 16 | 11 | 10,764 | 0-89 | 1,800*1,800 |

Note: The technical parameters above are only for your reference. Finalized details are subject to final contract.

As a professional hot top billet casting machine manufacturer and supplier based in China, Younger's production and operation are in strict accordance with international standards. We offer aluminium billet heating furnace, dust collector for melting furnace, aluminium quenching furnace, extrusion die heating furnace, and aluminium annealing furnace, etc. Located in Foshan City, we have access to convenient air, sea and land transportation. This guarantees lower transportation fees, reduces our production costs and saves customers on shipping charges. If you are interested in any of our furnaces, please feel free to contact us. The staff at Younger looks forward to working with you.

Upper Mould

Below Mould

Hydraulic System

Whole Moulds

Casting Puller

:。

Links:https://globefindpro.com/products/103504.html

-

Toilet Bus

Toilet Bus

-

Homogenizing Furnace

Homogenizing Furnace

-

School Bus YTK6660T3X

School Bus YTK6660T3X

-

Upward Casting Machine

Upward Casting Machine

-

Extrusion Die Heating Furnace

Extrusion Die Heating Furnace

-

Regenerative Type Aluminium Melting Furnace

Regenerative Type Aluminium Melting Furnace

-

Short Billet Heating Furnace

Short Billet Heating Furnace

-

MFCCE350 Continuous Extrusion Machine

MFCCE350 Continuous Extrusion Machine

-

Multi-Billet Heating Furnace With Hot Log Shear

Multi-Billet Heating Furnace With Hot Log Shear

-

Aging Furnace

Aging Furnace

-

Horizontal Winding Machine

Horizontal Winding Machine

-

Passenger Bus YTK6731

Passenger Bus YTK6731