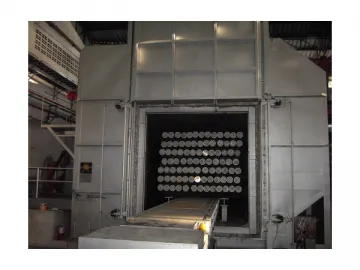

Regenerative Type Aluminium Melting Furnace

Regenerative type aluminium melting furnace is energy saving, save fuel by 30% comparison with old furnace.

Energy consumption comparison, take natural gas for example.

| burner type | gas consumption |

| old type | 80m3/T.Al |

| regenrative type | 65m3/T.Al |

Regenerative combustion system

Furnace type

From the appearance, regenerative type aluminium melting furnace has 2 types, round type and square type.

From constructure material, regenerative type aluminium melting furnace has 2 types, completely castable material type and high aluminium bricks castable materials

Delivery period

Regenerative type aluminium melting furnace will delivery within 60 days counting from contract comes into effective.

Local installation around 30 days for one set regenerative type melting furnace.

Elelctric debugging is around 10 days

Features

1. The regenerative type aluminium melting furnace is designed with two regenerative burners. This enables heat storage and release in turns and ensures high-efficient recycling of afterheat from flue gas.

2. The temperature of exhausted gas reduces from 790℃ to 150℃, which increases thermal-efficiency by 30%

3. The exhausted gas from the regenerative type aluminium melting furnace provides great convenience for the subsequent dedusting and desulfurization. The exhausted gas goes into the dedusting-bag directly without cooling.

4. There is low combustion noise.

5. There is little oxidation which hardly affects the molten metal.

Technical Parameters

| Model No. | Burning Type | Burner (pcs) | Chamber Max. Temperature (℃) | Capacity (kg) | Structure | Natural Gas Consumption (m³/T) | Total Power (kw) | Furnace Size L x W (mm) |

| YG-RL-Q/Y3 | Burner | 2 | 1150 | 3000 | Vertical door arch top | 75-85 | 12 | 2718*2660 |

| YG-RL-Q/Y5 | Burner | 2 | 1150 | 5000 | Vertical door arch top | 75-85 | 12 | 3933*3060 |

| YG-RL-Q/Y8 | Burner | 2 | 1150 | 8000 | Vertical door arch top | 75-85 | 15 | 4710*3700 |

| YG-RL-Q/Y10 | Regenerative | 2 | 1150 | 10000 | Tilting door arch top/flat top | ≤65 | 36 | 4924*3860 |

| YG-RL-Q/Y12 | Regenerative | 2 | 1150 | 12000 | Tilting door arch-top/flat top | ≤65 | 36 | 5000*4712 |

| YG-RL-Q/Y15 | Regenerative | 2 | 1150 | 15000 | Tilting door arch top/flat top | ≤65 | 40 | 5511*4556 |

| YG-RL-Q/Y18 | Regenerative | 2 | 1150 | 18000 | Tilting door arch top/flat top | ≤65 | 40 | 5851*4696 |

| YG-RL-Q/Y22 | Regenerative | 2 | 1150 | 22000 | Tilting door arch top/flat top | ≤65 | 45 | 6390*4900 |

| YG-RL-Q/Y25 | Regenerative | 2 | 1150 | 25000 | Tilting door/vertical door flat top | ≤65 | 45 | 6870*5440 |

| YG-RL-Q/Y30 | Regenerative | 2 | 1150 | 30000 | Tilting door/vertical door flat top | ≤65 | 60 | 6300*4400 |

Note: The technical parameters above are only for your reference. Finalized details are subject to final contract.

Thank you for visiting our products websites! As a professional aluminium melting furnace manufacturer and supplier based in China, Younger's production and operation are in strict accordance with international standards. We provide homogenizing furnace, billet heating furnace, aluminium quenching furnace, extrusion die heating furnace, aluminium annealing furnace, etc. Located in Foshan City, our company has easy access to convenient air, sea and land transportation. This guarantees lower transportation fees, reducing our production costs and saving customers on shipping charges. If you are interested in any of our furnaces, please feel free to contact us. The staff at Younger looks forward to working with you.

Links:https://globefindpro.com/products/103510.html