Energy Saving Unit

Energy Saving Unit

Product Description

The E680/K energy saving unit is especially designed forthe energy saving industries. It haseasy structure, making it easy for users operate the unit. The control loop is flexible in installation.Instantaneous frequency conversion function guarantees the continuity of theproduction. The cabinet mode enables usersto conveniently integrate the systems. The wind tunnel is completely independent, makingthe energy saving unit excellent in heat dissipation and features stability andlong service life.

Features

1. Power range: 7.5~110KW

2. The energy saving unit is equipped with V/F curve withmulti-joints, flexible in configuration.

3. Auto energy saving running, saving energy to a maximum.

4. It has functions like checking speed and operation recovery after power off.

5. The energy saving unithas auto voltage and current limitation functions, making the inverter run in astable and non-fault state for long time.

6. It has various analog input and output regulation modes.

7. It uses a standard built in PID adjuster,enabling users to closed loop control the flow and voltage.

8. The energy saving unit uses three way operation: control panel, terminalcontrol and long-distance communication control.

9. Frequency setting mode: digital keyboard setting mode, analog quantitysetting mode (based on voltage and current signal), long distance communicationsetting mode, PLC setting mode, etc. Combined and switched frequency settingmodes are available.

10. It uses double LED display, enabling users to monitor and adjust themolding machine simultaneously. It hasparameter copy functions by keyboard, making it convenient for the users tocopy the program among several inverters.

11. The energy saving unit uses the remote control keyboard. The stable communication distance can reach 1000m.

12. It is equipped with standard RS485 communicationinterface. The MODBUS and customized protocol are available. It has the function of linkage synchronizationcontrol, making the interconnection of inverter, PLC, IPC, and other equipmentpossible.

Typical Application

The energy saving units are used in energy-saving industries like electricpower, metallurgy, water pumps, fabrics, etc.

Note: The last letter of E680K means that the machine is without frequency conversion units. Users can choose the wires and accessoriesaccording to their own needs.

Technical Parameters

| Input | Rated voltage, rated frequency | 3 PH (4T# Series) 380V 50/60Hz | 3 PH (2T# Series) 220V 50/60Hz | 1 PH (2S# Series) 220V 50/60Hz | |

| Permissible voltage range | 3 PH (4T# Series) 320V~460V | 3 PH (2T# Series) 170V~270V | 1 PH (2S# Series) 170V~270V | ||

| Output | Voltage | 4T# Series: 0~380 V | 2S#, 2T# series: 0~220 V | ||

| Frequency | 0 Hz ~ 600Hz | ||||

| Overload capacity | 110% rated current for long-term; 150% rated current for 1m; 180% rated current for 2s. | ||||

| Control mode | VVVF control, space voltage vector | ||||

| Control characteristics | Frequency setting Resolution | Analog terminal input | 0.1% of maximum output frequency | ||

| Digital setting | 0.01 Hz | ||||

| External pulse | 0.1% of maximum frequency | ||||

| Frequency precision | Analog input | Within 0.2% of maximum output frequency | |||

| Digital input | Within 0.01% of setting output frequency | ||||

| External pulse | Within 0.1% of maximum output frequency | ||||

| Control characteristics | V/F curve (Voltage-frequency characteristics) | Reference frequency can be randomly set between 5Hz to 600Hz and V/F curve with multiple joint can be randomly set. There are three curves provided, including constant torque curve, Dec torque curve 1 and Dec torque curve 2. | |||

| Torque boost | Manual set: 0.0~20.0% of rated output. Automatic torque boost can be set according to output current. | ||||

| Auto current/voltage limit | It will automatically check the current and voltage of motor stator during acc/dec or stable running. Based on special arithmetic, it can control the current and voltage within allowable range. | ||||

| Under voltage inhibition in running | It is especially suitable for the users with low network voltage and frequently fluctuated network voltage. Even the voltage is lower than permissible voltage, and the system will maintain the longest possible running time according to the unique algorithm and residue energy allocation strategy. | ||||

| Typical functions | Multi-speed and wobble frequency running | 8 programmable multi-speed control and 6 kinds of running mode, 15 multi-speed control modes of terminal. Wobble frequency operation is composed of preset frequency, central adjustable frequency and state memorization and recovery after machine halt or power failure. | |||

| Embedded PID controller | The built-in PID controller with bipolar control is available. With accessories, the 5-pump constant-voltage regulation control system (supplying water and gas) is formed, and has various energy-saving functions such as sleeping mode, etc. | ||||

| RS485 communication and synchronous control/ load Self-equalizing function | With the standard RS485 communication interface, any master inverter can act as the synchronous controller, to internally command the linkage control proportion, superposition and fine adjustment of slave inverter and so on. With load self-equalizing function, the universal inverter can keep the strict conformance between the load proportion of all transmission devices and the pre-set proportion. | ||||

| Dedicated function of drawing machine | The energy saver has various functions such as coil diameter calculation, rapid and high-precision PID adjustment, disconnection protection and so on, to realize stable winding operation under various conditions. | ||||

| Droop speed control | Power equalization of many inverters on the same transmission chain can be realized. Proper parameters setting can realize the control performance of torque motor. | ||||

| Frequency setting | Analog input | DC voltage: 0~5V, 0~10V,DC current: 0~20mA (upper and lower setting, selectable) | |||

| Pulse input | Its amplitude value is between 5 and 30V and its frequency is within 50.0KHz. | ||||

| Digital input | It can set by operation panel, RS485 interface, UP/DW terminal, and can set multiple combinations with analogue input. | ||||

| Output signal | OC output | Two OC output, one fault relay output (TA, TB, TC) and as many as 16 types of output mode for choice | |||

| Analog output | Two 0~10V voltage signal or 0~20mA current signal. Upper and lower setting, available | ||||

| Energy saving running | Regulate the output voltage and slip frequency compensation according to the output current, getting the most efficient running results. Regulate the energy saving level according to the ambient working conditions. The energy saver is especially suitable for ball mill whose frequency can only be regulated slightly. | ||||

| Voltage stabilizing running | Three ways for selection: dynamic voltage regulation, static voltage regulation, instable voltage regulation, to get the most stable running result. | ||||

| Typical functions | Acc/Dec time setting | 0.1S~6000min continuous setting, S curve and linear mode for choice. | |||

| Check speed and restart function | Realize the steady restart when the machine is running or there is a machine halt. | ||||

| Counter and timer | Built in one timer and one counter, making the integration of system easy. | ||||

| Operating function | Upper and lower frequency setting, frequency hopping operation, reversal operation limitation, slip frequency compensation, voltage stabilizing running, RS485 communication, frequency increasing/decreasing control, self-recovery for fault, etc. | ||||

| Display | Operation panel display | Running state | Output frequency, output current and voltage, motor speed, frequency setting, module temperature, PID setting and feedback quantity, analog I/O and so on. | ||

| Alarming | The operation panel shows recent six times failure record, and last running parameter record of output frequency, setting frequency, output current, output voltage and DC voltage, module temperature and so on during last fault trip period. | ||||

| Protection / alarming function | Overcurrent, overvoltage, undervoltage, electronic thermal relay, overheating, short circuit, phase-lacking output, internal memory fault, etc. | ||||

| Environment | Ambient temperature | -10ºC to 50ºC (nonfreezing) | |||

| Ambient humidity | Under 90% (non-condensing) | ||||

| Ambient environment | Indoor (without corrosion, inflammable gas, oil mist or dust and so on) | ||||

| Altitude | Lower than 1000m | ||||

| Structure | IP protection | IP20 | |||

| Cooling mode | Forced cooling | ||||

| Installation | Cabinet model | ||||

SUNFAR is a major manufacturerand supplier of energy saving unit and frequency inverter, based in China. In addition to energy saving unit, we manufactureenergy saver for injection molding machine, high speed inverter, mini universalinverter, multi-pump constant pressure water supply control unit, etc. Our products are popular among the clientsfrom nearly 40 countries, including Germany,the United States, Britain, Egypt,Spain, Turkey, Russia,and South Africa. We hope you will like our products.

Links:https://globefindpro.com/products/104322.html

-

Dynamic Braking Unit (DBKU)

Dynamic Braking Unit (DBKU)

-

H320 High Speed Inverter

H320 High Speed Inverter

-

M320 Plastic Machine Inverter

M320 Plastic Machine Inverter

-

Energy Saver for Injection Molding Machine

Energy Saver for Injection Molding Machine

-

Multi-pump Constant Pressure Water Supply Control Unit

Multi-pump Constant Pressure Water Supply Control Unit

-

Self-Impact Crusher

Self-Impact Crusher

-

Splice Tray

Splice Tray

-

E2000 Fiber Optic Patch Cable

E2000 Fiber Optic Patch Cable

-

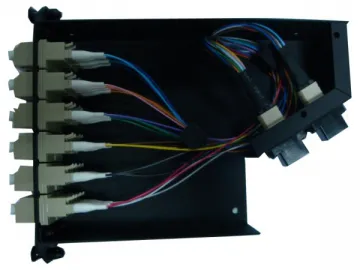

MPO Panel, MPO Cassette

MPO Panel, MPO Cassette

-

High Crushing Armored Fiber Optic Patch Cable

High Crushing Armored Fiber Optic Patch Cable

-

DIN Fiber Optic Patch Cable

DIN Fiber Optic Patch Cable

-

D4 Fiber Optic Patch Cable

D4 Fiber Optic Patch Cable