M320 Plastic Machine Inverter

M320 PlasticMachine Inverter

Features

1. Power range: 3.7 – 90KW

2. Inputvoltage range: 220V±20%, 380V±20%, 415V±15%

3. The plastic machine inverter adjusts thespeed smoothly and efficiently.

4. Itremains stabile even at low speed.

5. It has alow start current, smallest impact to the whole system.

6. It featuresan outstandingenergy saving effect: more than 30%.

7. The plastic machine inverter uses a large regulatingrange, high precision, making the machine easy to realize process automation.

8. It is small in size and easy to install.

9. It is equipped with double led displays, making itconvenient for users to adjust the machine. It can monitor two groups of parameters andmake users know the real-time information of operating conditions of theelectric machine.

10. The easy operating panel makes the operationfast. The parameters can be copied.

11. Coolingfan on/off selectable: reduce energy consumption of the plastic machine inverter.

12. It uses unique model-free adaptive and PWMtechnology, having an optimal control of the machine.

13. It is designed with reliable electric hardware,making the false rate to a minimum.

TypicalApplication

Theplastic machine inverter is used for plasticmachines, other machines with light loads, etc.

Technical Parameters

| Input | Rated voltage and frequency | Three-phase (4T****) 380V; 50/60Hz | Three-phase (2T****) 220V; 50/60Hz | |

| Voltage range | Three-phase (4T****) 300V ~ 460V | Three-phase (2T****) 170V~270V | ||

| Output | Voltage | Three-phase (4T****) 0 ~ 380V | Three-phase (2T****) 0~220 V | |

| Frequency | 0~200 Hz | |||

| Overload capacity | 110% rated current for long-term; 150% rated current for 1m; 180% rated current for 2s. | |||

| Control mode | VVVF control, space voltage vector | |||

| Control characteristics | Frequency setting resolution | Analog terminal input | 0.1% of maximum output frequency | |

| Digital setting | 0.01Hz | |||

| External pulse | 0.1% of maximum output frequency | |||

| Frequency precision | Analog input | Within 0.2% of maximum output frequency | ||

| Digital input | Within 0.01% of setting output frequency | |||

| External pulse | Within 0.1% of maximum output frequency | |||

| V/F curve (Voltage-frequency characteristics) | Reference frequency can be randomly set between 5Hz to 200Hz and V/F curve with multiple joint can also be randomly set. | |||

| Torque boost | Manual set: 0.0~20.0% of the rated output | |||

| Auto current/voltage limit | It will automatically check the current and voltage of motor stator during acc/dec or stable running. Based on special arithmetic, it can control the current and voltage within allowable range to ensure the minimum failure. | |||

| Under voltage suppression in running | It is especially suitable for the users with low network voltage and frequently fluctuated network voltage. Even the voltage is lower than permissible voltage, and the system will maintain the longest possible running time according to the unique algorithm and residue energy allocation strategy. | |||

| Typical functions | Frequency setting | Analog input | DC voltage: 0~5V, 0~10V,DC current: 0~20mA (upper and lower setting, selectable) | |

| Pulse input | Its amplitude value is between 5 and 30V, and its frequency is within 50.0KHz. | |||

| Digital input | It can set by operation panel, RS485 interface, UP/DW terminal, and can set multiple combinations with analogue input. | |||

| Output signal | OC output | Two OC output, one fault relay output (TA, TB, TC) and as many as 16 types of output mode for choice | ||

| Analog output | Two 0~10V voltage signal or 0~20mA current signal. Upper and lower setting, available | |||

| Voltage stabilizing running | Three ways for selection: dynamic voltage regulation, static voltage regulation, instable voltage regulation, to get the most stable running result. | |||

| Acc/Dec time setting | 0.1S~6000min continuous setting, S curve and linear mode for choice | |||

| Operating function | Upper and lower frequency setting, frequency hopping operation, reversal operation limitation, voltage stabilizing running, RS485 communication, voltage stabilizing running, frequency increasing/decreasing control, etc. | |||

| Display | Operation panel display | Running state | Output frequency, output current and voltage, motor speed, frequency setting, module temperature, and feedback quantity, analog I/O and so on. | |

| Alarming | The operation panel shows recent six times failure record, and last running parameter record of output frequency, setting frequency, output current, output voltage and DC voltage, module temperature and so on during last fault trip period. | |||

| Protection / alarming function | Overcurrent, overvoltage, undervoltage, electronic thermal relay, overheating, short circuit, internal memory fault, etc. | |||

| Environment | Ambient temperature | -10ºC to 50ºC (nonfreezing) | ||

| Ambient humidity | Under 90% (non-condensing) | |||

| Ambient environment | Indoor (without corrosion, inflammable gas, oil mist or dust and so on) | |||

| Altitude | Lower than 1000m | |||

| Structure | IP protection | IP20 | ||

| Cooling mode | Forced cooling | |||

| Installation | Wall-hanging mode | |||

Foundedin 2004, SUNFAR is an experienced manufacturer of frequency inverter, basedin China. We specialize in the production ofplastic machine inverter, universal inverter, high speed inverter, energysaving unit, and so on. As a result oftheir superior quality and competitive prices, our inverters are sought afterby customers in Chile, Argentina, Iran,Germany, the United States, Peru,Portugal,and more. We look forward to workingwith more global customers. We areconfident you will be satisfied with our products.

Links:https://globefindpro.com/products/104329.html

-

Energy Saver for Injection Molding Machine

Energy Saver for Injection Molding Machine

-

Multi-pump Constant Pressure Water Supply Control Unit

Multi-pump Constant Pressure Water Supply Control Unit

-

Self-Impact Crusher

Self-Impact Crusher

-

Cone Crusher

Cone Crusher

-

Board Book

Board Book

-

C320 Open-loop Vector Control Inverter

C320 Open-loop Vector Control Inverter

-

H320 High Speed Inverter

H320 High Speed Inverter

-

Dynamic Braking Unit (DBKU)

Dynamic Braking Unit (DBKU)

-

Energy Saving Unit

Energy Saving Unit

-

Splice Tray

Splice Tray

-

E2000 Fiber Optic Patch Cable

E2000 Fiber Optic Patch Cable

-

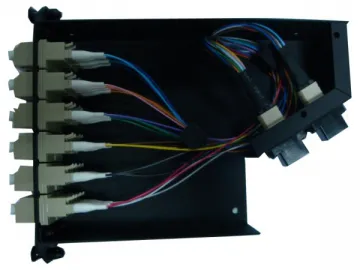

MPO Panel, MPO Cassette

MPO Panel, MPO Cassette