CNC Hydraulic Press Brake, WC67K Series Economic Type

CNC Hydraulic Press Brake, WC67K Series Economic Type

Features

1. Like WC67Y series CNC hydraulic press brake, WC67K series CNC hydraulic press brake also adopts welded-structure frame.

2. It utilizes an economical type CNC system which is specially developed for the bending machine.

3. The back gauge adopts imported ball screw and linear guideway.

Applications

The CNC hydraulic press brake is widely used for bending and forming of doors, windows, steel structures, etc. With reliable quality and competitive price, it is very popular in the sheet metal industry.

Technical Specifications of Economic Type CNC Hydraulic Press Brake

WC67K-40/2000 | WC67K-40/2500 | WC67K-63/2500 | WC67K-80/2500 | WC67K-80/3200 | WC67K-80/4000 | WC67K-100/2500 | WC67K-100/3200 | WC67K-100/4000 | ||

Nominal force | kN | 400 | 400 | 630 | 800 | 800 | 800 | 1000 | 1000 | 1000 |

Length of table | mm | 2000 | 2500 | 2500 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 |

Distance between uprights | mm | 1650 | 2000 | 2000 | 1990 | 2600 | 3350 | 1650 | 2550 | 3350 |

Throat depth | mm | 200 | 200 | 250 | 280 | 280 | 280 | 320 | 320 | 320 |

Ram stroke | mm | 100 | 100 | 100 | 100 | 100 | 100 | 130 | 130 | 130 |

Stroke adjustment | mm | 80 | 80 | 80 | 80 | 80 | 80 | 100 | 100 | 100 |

Max.opening height | mm | 330 | 330 | 340 | 360 | 360 | 360 | 390 | 390 | 390 |

Stokes | Min-1 | ≥11 | ≥11 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 |

Main motor capacity | kW | 4 | 4 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Net weight | kg | 3000 | 3600 | 4600 | 5300 | 6400 | 8300 | 7300 | 8200 | 9400 |

Outline dimensions(L×W×H) | mm | 250019002240 | 300019502240 | 310019002380 | 315019502350 | 382019502350 | 465019502350 | 320019602450 | 379019802450 | 460019802450 |

WC67K-125/2500 | WC67K-125/3200 | WC67K-160/2500 | WC67K-160/3200 | WC67K-160/4000 | WC67K-160/6000 | WC67K-200/3200 | WC67K-200/4000 | ||

Nominal force | kN | 1250 | 1250 | 1600 | 1600 | 1600 | 1600 | 2000 | 2000 |

Length of table | mm | 2500 | 3200 | 2500 | 3200 | 4000 | 6000 | 3200 | 4000 |

Distance between uprights | mm | 1850 | 2550 | 1950 | 2540 | 3140 | 4800 | 2550 | 3260 |

Throat depth | mm | 320 | 320 | 330 | 330 | 330 | 330 | 350 | 350 |

Ram stroke | mm | 130 | 130 | 200 | 200 | 200 | 200 | 200 | 200 |

Stroke adjustment | mm | 100 | 100 | 150 | 150 | 150 | 150 | 150 | 150 |

Max.opening height | mm | 390 | 390 | 465 | 465 | 465 | 465 | 450 | 450 |

Stokes | Min-1 | ≥10 | ≥10 | ≥6 | ≥6 | ≥6 | ≥6 | ≥3 | ≥3 |

Main motor capacity | kW | 7.5 | 7.5 | 11 | 11 | 11 | 11 | 15 | 15 |

Net weight | kg | 8100 | 9300 | 10100 | 11200 | 12700 | 22100 | 12600 | 13700 |

Outline dimensions(L×W×H) | mm | 320019802450 | 379019802450 | 320022502560 | 379022502560 | 470022502560 | 607021602860 | 375021802700 | 445021802700 |

WC67K-200/6000 | WC67K-250/3200 | WC67K-250/4200 | WC67K-250/5000 | WC67K-250/6000 | WC67K-300/4000 | ||

Nominal force | kN | 2000 | 2500 | 2500 | 2500 | 2500 | 3000 |

Length of table | mm | 6000 | 3200 | 4200 | 5000 | 6000 | 4000 |

Distance between uprights | mm | 4800 | 2540 | 3140 | 4000 | 5000 | 2900 |

Throat depth | mm | 350 | 400 | 400 | 400 | 400 | 400 |

Ram stroke | mm | 200 | 250 | 250 | 250 | 250 | 250 |

Stroke adjustment | mm | 150 | 180 | 180 | 180 | 180 | 180 |

Max.opening height | mm | 450 | 500 | 500 | 500 | 500 | 535 |

Stokes | Min-1 | ≥3 | ≥3 | ≥3 | ≥3 | ≥3 | ≥3 |

Main motor capacity | kW | 15 | 18.5 | 18.5 | 18.5 | 18.5 | 22 |

Net weight | kg | 23100 | 13900 | 16300 | 19900 | 25100 | 24400 |

Outline dimensions(L×W×H) | mm | 642021802900 | 384022502980 | 484022502980 | 564022502980 | 642022502980 | 440022503115 |

WC67K-300/5000 | WC67K-300/6000 | WC67K-400/4000 | WC67K-400/6000 | WC67K-500/4000 | WC67K-600/6000 | ||

Nominal force | kN | 3000 | 3000 | 4000 | 4000 | 5000 | 5000 |

Length of table | mm | 5000 | 6000 | 4000 | 6000 | 4000 | 6000 |

Distance between uprights | mm | 3900 | 4900 | 3140 | 5000 | 3140 | 4760 |

Throat depth | mm | 400 | 400 | 400 | 400 | 400 | 400 |

Ram stroke | mm | 250 | 250 | 320 | 320 | 320 | 320 |

Stroke adjustment | mm | 180 | 180 | 220 | 220 | 220 | 220 |

Max.opening height | mm | 535 | 535 | 600 | 600 | 630 | 630 |

Stokes | Min-1 | ≥3 | ≥3 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 |

Main motor capacity | kW | 22 | 22 | 37 | 37 | 37 | 37 |

Net weight | kg | 28100 | 29100 | 33100 | 46100 | 42000 | 47600 |

Outline dimensions(L×W×H) | mm | 540022503115 | 640022503315 | 480026253700 | 680026503700 | 420045004760 | 620045004760 |

Main Material

Cast iron

Maintenance

1. a. Check the oil level in an oil tank every week. You should also check the oil level after hydraulic system maintenance. If the oil level is below the oil window, please add hydraulic oil to the tank immediately.

b. For a new CNC hydraulic press brake, you should replace the hydraulic oil after it has been operated for 2,000 hours. Since then, you just need to replace oil every 4,000 to 6,000 hours of operation. Please clean the oil tank before oil replacement.

c. You’d better keep the oil temperature at 35℃ to 60℃. This is because the oil and spare parts may be damaged if the oil temperature exceeds 70℃.

2. Filter

a. Every time you replace the hydraulic oil, please replace or thoroughly clean the filter.

b. If there is some problem with the filter, please replace it immediately.

c. The air filter on the oil tank should be checked and cleaned every 3 months, and be replaced every one year.

3. Hydraulic components

a. In order to prevent dirt from entering the system, please clean hydraulic components every month, such as valve, motor, pump, oil tube, etc. Please don’t use any detergents.

b. If a new CNC hydraulic press brake has been used for a month, please check whether the bend of oil tube is deformed, and replace the tube timely if there is any deformation. And fasten all connections of spare parts after the new machine has been used for two months. Please shut off the machine before performing this task.

Packaging

1. Wood packaging for export, according to customers’ specific suffocating requirements

2. Plywood packaging

Service

1. We offer a one-year warranty on our CNC hydraulic press brake. During the warranty period, spare parts are replaced free of charge.

2. We will not compensate loss if the problem is caused by improper operation or other human errors.

Links:https://globefindpro.com/products/105036.html

-

CNC Hydraulic Press Brake, WC67K Series Tandem Economic Type

CNC Hydraulic Press Brake, WC67K Series Tandem Economic Type

-

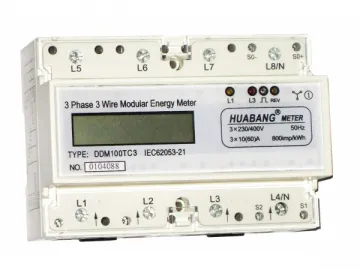

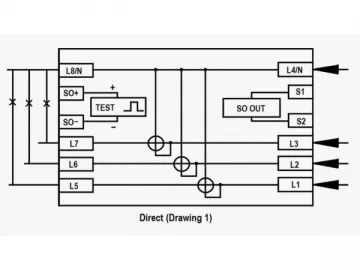

Three Phase Three Wire DIN-rail Active Energy Meter

Three Phase Three Wire DIN-rail Active Energy Meter

-

Vertical Metal Cutting Bandsaw, GY Series

Vertical Metal Cutting Bandsaw, GY Series

-

CNC Hydraulic Swing Beam Shear, QC12K Series Economic Type

CNC Hydraulic Swing Beam Shear, QC12K Series Economic Type

-

DDM100SCFR DIN-rail Energy Meter,Multi-Tariff With Communication Port, 4 Pole/Modular

DDM100SCFR DIN-rail Energy Meter,Multi-Tariff With Communication Port, 4 Pole/Modular

-

Single Phase Two Wire DIN-rail Active Energy Meter

Single Phase Two Wire DIN-rail Active Energy Meter

-

DDM100SCF DIN-rail Energy Meter, Multi-Tariff, 4 Pole/Modular

DDM100SCF DIN-rail Energy Meter, Multi-Tariff, 4 Pole/Modular

-

Electronic Energy Meter (Front Board Mounted Static KWH Meter)

Electronic Energy Meter (Front Board Mounted Static KWH Meter)

-

Hydraulic Guillotine Shear, QC11Y Series

Hydraulic Guillotine Shear, QC11Y Series

-

Hydraulic Swing Beam Shear, QS12Y Series Deep Throat Type

Hydraulic Swing Beam Shear, QS12Y Series Deep Throat Type

-

DDM100TCF Multi-Tariff DIN-rail Energy Meter, 7 Pole/Modular

DDM100TCF Multi-Tariff DIN-rail Energy Meter, 7 Pole/Modular

-

DDM100TR DIN-rail Energy Meter With Communication Port, 7 Pole/Modular

DDM100TR DIN-rail Energy Meter With Communication Port, 7 Pole/Modular