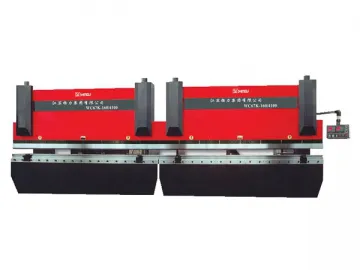

CNC Hydraulic Press Brake, WC67K Series Tandem Economic Type

CNC Hydraulic Press Brake, WC67K Series Tandem Economic Type

Features

1. The hydraulic bending machine consists of two WC67K series CNC hydraulic press brakes of the same specification, and is equipped with a synchronizing linkage.

2. It is ideal for processing ultra long workpieces.

3. Both of the main machines can operate independently, thus increasing production efficiency.

Applications

Zhongying CNC hydraulic press brake is widely used in the sheet metal industry. It is ideal for bending, forming operations in the manufacture of automobiles, doors, windows, etc.

Technical Specifications of Tandem Economic Type CNC Hydraulic Press Brake

2-WC67K-100/3200 | 2-WC67K-100/4000 | 2-WC67K-160/4000 | 2-WC67K-250/3200 | 2-WC67K-250/4200 | ||

Nominal force | kN | 21000 | 21000 | 21600 | 22500 | 22500 |

Length of table | mm | 23200 | 24000 | 24000 | 23200 | 24200 |

Distance between uprights | mm | 2550 | 3350 | 3140 | 2540 | 3140 |

Throat depth | mm | 320 | 320 | 320 | 400 | 400 |

Ram stoke | mm | 130 | 130 | 200 | 250 | 250 |

Stroke adjustment | mm | 100 | 100 | 150 | 180 | 180 |

Max.opening height | mm | 390 | 390 | 440 | 500 | 500 |

Strokes | Min-1 | ≥10 | ≥10 | ≥6 | ≥3 | ≥3 |

Main motor capacity | kW | 7.5 | 7.5 | 11 | 18.5 | 18.5 |

Net weight | kg | 28200 | 29300 | 212600 | 213800 | 216200 |

Outline dimensions(L×W×H) | mm | 640014802650 | 800014802650 | 800017802570 | 640018902815 | 840018902815 |

2-WC67K-250/5000 | 2-WC67K-250/6000 | 2-WC67K-300/5000 | 2-WC67K-300/6000 | 2-WC67K-400/6000 | 2-WC67K-500/6000 | ||

Nominal force | kN | 22500 | 22500 | 23000 | 23000 | 24000 | 25000 |

Length of table | mm | 25000 | 26000 | 25000 | 26000 | 26000 | 26000 |

Distance between uprights | mm | 4000 | 5000 | 3900 | 4900 | 5000 | 5050 |

Throat depth | mm | 400 | 400 | 400 | 400 | 450 | 450 |

Ram stoke | mm | 250 | 250 | 250 | 250 | 300 | 300 |

Stroke adjustment | mm | 180 | 180 | 180 | 180 | 220 | 220 |

Max.opening height | mm | 500 | 500 | 535 | 535 | 630 | 650 |

Strokes | Min-1 | ≥3 | ≥3 | ≥3 | ≥3 | ≥2.5 | ≥2.5 |

Main motor capacity | kW | 18.5 | 18.5 | 22 | 22 | 30 | 37 |

Net weight | kg | 219800 | 225000 | 228000 | 229200 | 246000 | 247500 |

Outline dimensions(L×W×H) | mm | 1000018902815 | 1200018902815 | 1000019503115 | 120001950(3015 300) | 120003000(3660 1100) | 120003200(3660 1100) |

Main Material

Cast iron

Maintenance

1. a. Check the oil level in an oil tank every week. You should also check the oil level after hydraulic system maintenance. If the oil level is below the oil window, please add hydraulic oil to the tank immediately.

b. For a new tandem CNC hydraulic bending machine, you should replace the hydraulic oil after it has been operated for 2,000 hours. Since then, you just need to replace oil every 4,000 to 6,000 hours of operation. Please clean the oil tank before oil replacement.

c. You’d better keep the oil temperature at 35℃ to 60℃. This is because the oil and spare parts may be damaged if the oil temperature exceeds 70℃.

2. Filter

a. Every time you replace the hydraulic oil, please replace or thoroughly clean the filter.

b. If there is some problem with the filter, please replace it immediately.

c. The air filter on the oil tank should be checked and cleaned every 3 months, and be replaced every one year.

3. Hydraulic components

a. In order to prevent dirt from entering the system, please clean hydraulic components every month, such as valve, motor, pump, oil tube, etc. Please don’t use any detergents.

b. If a new tandem CNC hydraulic bending machine has been used for a month, please check whether the bend of oil tube is deformed, and replace the tube timely if there is any deformation. And fasten all connections of spare parts after the new machine has been used for two months. Please shut off the machine before performing this task.

Packaging

1. Wood packaging for export, according to customers’ specific suffocating requirements

2. Plywood packaging

Service

1. We offer a one-year warranty on our CNC hydraulic bending machine. During the warranty period, spare parts are replaced free of charge.

2. We will not compensate loss if the problem is caused by improper operation or other human errors.

Links:https://globefindpro.com/products/105037.html

-

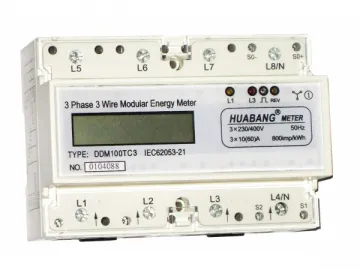

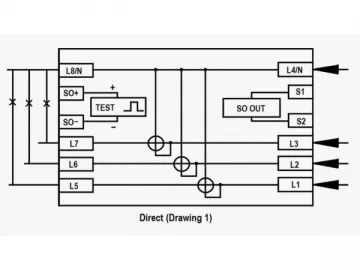

Three Phase Three Wire DIN-rail Active Energy Meter

Three Phase Three Wire DIN-rail Active Energy Meter

-

Vertical Metal Cutting Bandsaw, GY Series

Vertical Metal Cutting Bandsaw, GY Series

-

CNC Hydraulic Swing Beam Shear, QC12K Series Economic Type

CNC Hydraulic Swing Beam Shear, QC12K Series Economic Type

-

DDM100SCFR DIN-rail Energy Meter,Multi-Tariff With Communication Port, 4 Pole/Modular

DDM100SCFR DIN-rail Energy Meter,Multi-Tariff With Communication Port, 4 Pole/Modular

-

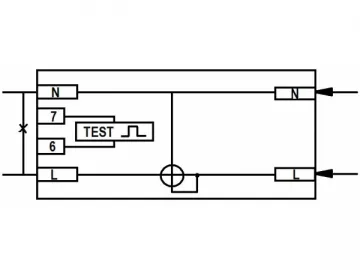

Single Phase Two Wire DIN-rail Active Energy Meter

Single Phase Two Wire DIN-rail Active Energy Meter

-

DDM100 DIN-rail Energy Meter, 4 Pole/Modular

DDM100 DIN-rail Energy Meter, 4 Pole/Modular

-

CNC Hydraulic Press Brake, WC67K Series Economic Type

CNC Hydraulic Press Brake, WC67K Series Economic Type

-

DDM100SCF DIN-rail Energy Meter, Multi-Tariff, 4 Pole/Modular

DDM100SCF DIN-rail Energy Meter, Multi-Tariff, 4 Pole/Modular

-

Electronic Energy Meter (Front Board Mounted Static KWH Meter)

Electronic Energy Meter (Front Board Mounted Static KWH Meter)

-

Hydraulic Guillotine Shear, QC11Y Series

Hydraulic Guillotine Shear, QC11Y Series

-

Hydraulic Swing Beam Shear, QS12Y Series Deep Throat Type

Hydraulic Swing Beam Shear, QS12Y Series Deep Throat Type

-

DDM100TCF Multi-Tariff DIN-rail Energy Meter, 7 Pole/Modular

DDM100TCF Multi-Tariff DIN-rail Energy Meter, 7 Pole/Modular