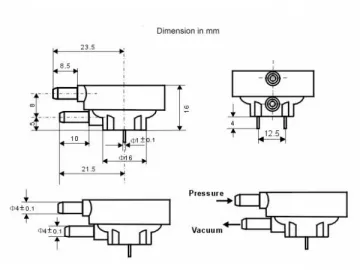

HP-3 Extended Duty Pressure Switch

The extended duty pressure switch is specifically designed to stand up to extended duty applications. This switch is factory set but capable of field adjustment. The extended duty pressure switch features different diaphragms for compatibility with a wide variety of fluids, and various terminations including a Metric-Pack connector that forms a tight seal when connected. Among the outstanding design benefits are its durable construction, compact size, and enhanced set point integrity. It can be widely used for pool and spa, anti-skid braking systems, water pump systems, dental air compressors, etc.

Model | HP-3 |

Medium | Air, motor oils, transmission oils, jet fuels and other similar hydrocarbon medium; water (provide with special diaphragm material) |

Pressure Set Point | Factory set from 0.5 to 150 PSI |

Max Operating Pressure | 150 PSI for 0.5-24 PSI set point range 250 PSI for 25-150 PSI set point range |

Proof Pressure | 500 PSI |

Burst Pressure | 750 PSI for 0.5-24 PSI set point range 1250 PSI for 25-150 PSI set point range |

Operating Temperature Range | -40° C to ~ 120° C |

Switch Type | Direct action, blade contact |

Electric Rating | Resistive: 15 AMP- 6 VDC 8 AMP- 12 VDC 4 AMP- 24 VDC Inductive: 1 AMP- 120 VAC 0.5 AMP- 240 VAC |

Contact Arrangement | SPST-N.O., N.C., 1 circuit adjustable dual circuit or 2 circuits adjustable dual circuit. N.O./N.O. dual circuit and N.C./N.C. dual circuit |

Terminals | #8-32 screws, 1/4” blade |

Connection | 1/8"NPT Male, 1/4"NPT Male, G1/8" Male, G1/4" Male |

Material | Contact: Silver alloy, gold plated Base: Brass Cover: Glass reinforced polyester Diaphragm: Polyimide film (other materials is optional according to medium) |

Options | Plated Steel, plastic or stainless steel base, various base connector thread sizes; wire leads (potted & sealed). |

Links:https://globefindpro.com/products/105823.html

-

PL02 Pressure Switch (5-1000 mbar)

PL02 Pressure Switch (5-1000 mbar)

-

RL-4 Automatic Electronic-leveling Rotary Laser Level

RL-4 Automatic Electronic-leveling Rotary Laser Level

-

Dual-layer Storage Tank

Dual-layer Storage Tank

-

Fresh Milk and Yoghourt Two-purpose Plate Type Whole Set Sterilizing Equipment

Fresh Milk and Yoghourt Two-purpose Plate Type Whole Set Sterilizing Equipment

-

RL-5 Self-leveling Rotary Laser Level

RL-5 Self-leveling Rotary Laser Level

-

High Temperature Sterilizer (HTST)

High Temperature Sterilizer (HTST)

-

Bouncy Balls

Bouncy Balls

-

PA04 Air Pressure Switch

PA04 Air Pressure Switch

-

HP-5 High Pressure Switch

HP-5 High Pressure Switch

-

HS-2 Air Switch (20-800 mbar)

HS-2 Air Switch (20-800 mbar)

-

HP-4 Vacuum Switch

HP-4 Vacuum Switch

-

PL04 Pressure Switch (37-8500 Pa)

PL04 Pressure Switch (37-8500 Pa)