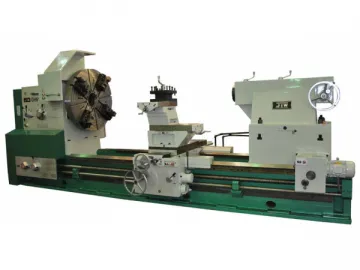

Horizontal Lathe WC61160Z

HorizontalLathe WC61160Z

Features

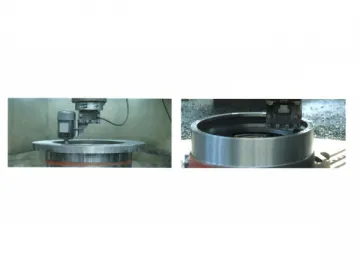

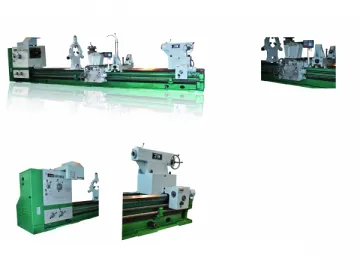

1. Theheavy duty lathes WC61160Z, WC61180Z, WC61200Z, WC61220Z, WC61240Z areuniversal engine lathes, suitable for cutting swing work pieces, such asexternal cylindrical surfaces turning, internal hole, taper and threadmachining, etc.

2. Three guide ways have been adopted. The horizontallathe WC61160Z has features of strong rigidity, heavy loading capacity andgood accuracy.

3. DC driving is used as the main driving of the machine, full digital DCvariable, 3 grade mechanical or hydraulic speed change has been equipped, and the spindle speed range 1:200may be got.

4. The feed driving is connected with the main driving and the carriage has thefunction of rapid traverse and combined feeding.

5. The built-in living center has been selected by the tailstock. Thishorizontal lathe has characteristics of heavy loading capacity, 2 grade manualtraversing function, and the traversing of the tailstock is motorized and easyto operate.

6. A double-row short cylinder roller bearing is used by spindle bearing. Ithas high accuracy and radial clearance may be adjusted by it.

| Specifications | WC61160Z | WC61180Z | WC61200Z | WC61220Z | WC61240Z | Standard Equipment |

| Swing over bed | 1600mm | 1800mm | 2000mm | 2200mm | 2400mm | 4-jaw chuck |

| Swing over cross slide | 1250mm | 1450mm | 1650mm | 1850mm | 2050mm | Tool box |

| Centers distance | 3m, 4m, 5m, 6m, 8m, 10m, 12m, 16m | Close steady rest | ||||

| Max. weight of work piece between centers | 32T | |||||

| Bed width | 1600mm | |||||

| Headstock | ||||||

| Spindle bore | 85mm | Optional Accessories | ||||

| Spindle taper | ф120mm taper 17 | Open steady rest | ||||

| Range of spindle speed | 0.86~160r/min manual operated gear 3 infinite speed variation (hydraulic) | |||||

| Feed box | ||||||

| Metric threads range (pitch) | 2-40mm | |||||

| Inch thread range | 1-14 | |||||

| Worm thread range (Module) | 1.5-20mm | |||||

| Longitudinal feeding range | 0.125-4.8mm/spindle each lap | |||||

| Cross feeding range | 0.063-2.4mm/spindle each lap | |||||

| Fast travel (longitudinal/cross) | 3000mm/min, 1500mm/min | |||||

| Tool rest | ||||||

| Tool section | 70 x 70mm | |||||

| Carriage | ||||||

| Max. cross travel of carriage | 700mm | |||||

| Max. travel of middle tool rest | 600mm | |||||

| Tailstock | ||||||

| Dia. of tailstock quill | 300mm | |||||

| Taper of tailstock quill | ф100 taper 17 | |||||

| Max. travel of tailstock quill | 300mm | |||||

| Steady rest | ||||||

| Close-type steady rest | ф400-750mm | |||||

| Open-type steady rest | ф650-1200mm | |||||

| Motor | ||||||

| Main motor | 80kw (DC) | |||||

| Fast feeding motor | 1.5kw | |||||

| Fast feeding motor in tailstock | 1.5kw | |||||

| Centers distance N.W. Overall Dimension | 3000mm | 37500kg | 8600x2480x2280mm | |||

| 4000mm | 39000kg | 9600x2480x2280mm | ||||

| 5000mm | 40500kg | 10600x2480x2280mm | ||||

| 6000mm | 42000kg | 11600x2480x2280mm | ||||

| 8000mm | 45000kg | 13600x2480x2280mm | ||||

| 10000mm | 48000kg | 15600x2480x2280mm | ||||

| 12000mm | 52000kg | 17600x2480x2280mm | ||||

| 16000mm | 58000kg | 21600x2480x2280mm | ||||

| Specifications | WC61160Z/63 | WC61180Z/63 | WC61200Z/63 | WC61220Z/63 | WC61240Z/63 | Standard Equipment |

| Swing over bed | 1600mm | 1800mm | 2000mm | 2200mm | 2400mm | 4-jaw chuck |

| Swing over cross slide | 1250mm | 1450mm | 1650mm | 1850mm | 2050mm | Tool box |

| Centers distance | 3m, 4m, 5m, 6m, 8m, 10m, 12m, 16m | Close steady rest | ||||

| Max. weight of work piece between centers | 63T | |||||

| Bed width | 2100mm | |||||

| Headstock | ||||||

| Spindle bore | 85mm | Optional Accessories | ||||

| Spindle taper | ф120mm taper 17 | Open steady rest | ||||

| Range of spindle speed | 0.625~125r/min manual operated gear 3 infinite speed variation(hydraulic) | |||||

| Feed box | ||||||

| Metric threads range (pitch) | 2-40mm | |||||

| Inch thread range | 1-14 | |||||

| Worm thread range (Module) | 1.5-20mm | |||||

| Longitudinal feeding range | 0.125-4.8mm/spindle each lap | |||||

| Cross feeding range | 0.063-2.4mm/spindle each lap | |||||

| Fast travel (longitudinal/cross) | 3000mm/min, 1500mm/min | |||||

| Tool rest | ||||||

| Tool section | 70 x 70mm | |||||

| Carriage | ||||||

| Max. cross travel of carriage | 900mm | |||||

| Max. travel of middle tool rest | 600mm | |||||

| Tailstock | ||||||

| Dia. of tailstock quill | 500mm | |||||

| Taper of tailstock quill | ф160mm taper 17 | |||||

| Max. travel of tailstock quill | 300mm | |||||

| Steady rest | ||||||

| Close-type steady rest | ф400-750mm | |||||

| Open-type steady rest | ф650-1200mm | |||||

| Motor | ||||||

| Main motor | 110kw (DC) | |||||

| Fast feeding motor | 1.5kw | |||||

| Fast feeding motor in tailstock | 1.5kw | |||||

| Centers distance N.W. Overall Dimension | 3000mm | |||||

| 4000mm | ||||||

| 5000mm | ||||||

| 6000mm | ||||||

| 8000mm | ||||||

| 10000mm | ||||||

| 12000mm | ||||||

| 16000mm | ||||||

Established in Chinain 1993, J&W is a horizontal lathe manufacturer and supplier. Our companyprovides a vast range of products that include our vertical lathe, double columnmachining center, CNC lathe, boring milling machine, and others.

Links:https://globefindpro.com/products/106569.html