Vertical Lathe (S) LC630Q

Vertical Lathe (S) LC630Q

Features

1. This series vertical latheis used for finely and roughly turning cylinder and inner hole, inner and outertaper, surfacing, grooving, threading and curving of the ferrous, nonferrousmetal and some kinds of non-metal materials with hard-alloyed and porcelaintools.

2. This series verticallathe is divided into the universal type and the CNC type, while the CNCmachines have standard and heavy-duty types.

3. The main drive is provided by DC motor by a two-step vertical axle speed-changingdevice to engage in table speed-change.

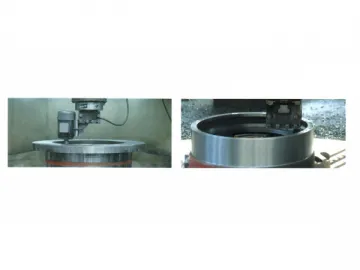

4. The table spindle is centered by a high-precision double-row short rollerbearing whose radial clearance can be adjusted. With constant flow hydrostaticguideway and oil temperature device applied in axial direction, the table hasfeatures of higher swivel precision, larger load ability and smaller thermaldeformation.

5. AC servomotors, which drive the ball-screw via rated gear-set to control theheads to feed or rapid move, composes the feed system of the vertical lathe.

6. The CNC machine's vertical head uses a constant flow hydrostatic guideway inhorizontal direction while the ram uses a rolling and sliding compoundguideway.

7. Per customer's requirement, digital display unit, grinding head of electricspindle can be provided.

8. The left column and right one are fixed directly on foundation separatelyinstead of connecting with the table. This kind of construction eliminates themutual influence of spindle transmission, feed and thermal deformation, whichalso improve the whole precision and is convenient for precision regulation.

| Specifications | (S)LC630Q | (S)LC800Q | (S)LC1000Q | |||

| Table diameter | 5700~6000mm | 5700~7100mm | 7100~7500mm | |||

| Max. turning diameter | 6300mm | 8000mm | 10000mm | |||

| Max. height of work piece | 3150~4500mm | 4000~5000mm | 4000~5000mm | |||

| Max. weight of work piece | 50~150T | 50~250T | 50~320T | |||

| Power of main motor | DC 90/110kw | DC 90/110/125kw | DC 132kw | |||

| Max. torque of table | 150kN.m | 500kN.m | 460kN.m | 630kN.m | 640kN.m | |

| Table speed | 0.32 ~ 32 r/min | 0.16 ~ 16 r/min | ||||

| Ram travel | 2760mm | |||||

| Ram section dimension | 280mm | 400mm | 320mm | 400mm | 320mm | 400mm |

| Horizontal travel of head | -50~3400mm | -20~4400mm | -20~5400mm | |||

| Cutting force of right head | 125kN | 100kN | ||||

| Cutting force of left head | 100kN | 80kN | ||||

| Rapid travel of head | 4000mm/min | |||||

| Guideway pair of table | Hydrostatic | |||||

| Swivel of head | □ 280 | -15°~ 30° | ||||

| □ 320 | ||||||

| □ 360 | ±15° | |||||

As a professional vertical lathe manufacturer based in China, we provide an extensive range of products, including boring milling machine, horizontal lathe, double column machining center, and others.

Links:https://globefindpro.com/products/106573.html

-

Raschel Bag TDRB-002

Raschel Bag TDRB-002

-

Knitted Bag TDRBT-013

Knitted Bag TDRBT-013

-

Bale Net Wrap PENW-002

Bale Net Wrap PENW-002

-

CNC Lathe SK6140H, SK6152H

CNC Lathe SK6140H, SK6152H

-

CNC Lathe SK6132H, SK6136H

CNC Lathe SK6132H, SK6136H

-

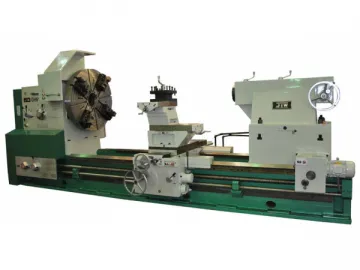

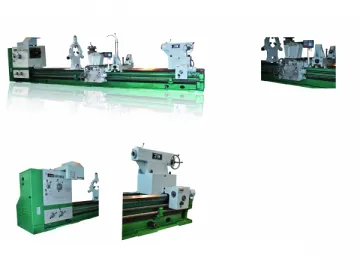

Horizontal Lathe GH62100Z, GH6280Z

Horizontal Lathe GH62100Z, GH6280Z

-

Horizontal Lathe GH61208Z

Horizontal Lathe GH61208Z

-

Pallet Netwrap PEPN-001

Pallet Netwrap PEPN-001

-

Bale Net Wrap PENW-004

Bale Net Wrap PENW-004

-

Horizontal Lathe WC61160Z

Horizontal Lathe WC61160Z

-

Horizontal Lathe GH61100Z

Horizontal Lathe GH61100Z

-

Vertical Lathe LC350Q

Vertical Lathe LC350Q