Tile Forming Machine

Tile Forming Machine

The glazed tile produced by this kind of tile forming machine looks beautiful, elegant and noble. They can be used in garden-style factories, traveling scenic spots, hotels, exhibition centers, villas, civil construction and more.

Main Equipment

This kind of tile forming machine consists of a manual decoyer, feeding platform, main molding core, shearing mechanism, hydraulic station, computer control cabinet, step-pressed mechanism, high precision counter and driven system protective covering panel supporting table.

Flow Chart

Decoiling-active feeding –Roll forming--Step press -Measuring length-cutting to length-product to stand

Technical Parameters

Item | Description |

Material Width | 914mm-1250mm |

Material Thickness | 0.4mm-0.8mm |

Material | PPGI HDGI |

Yield Stress | 235Mpa |

Material of Roller | 45# steel plant hard chromium 0.05mm |

Diameter of Shaft | 80mm |

Voltage | AC380v/50hz or per customer’s requirement |

Motor Power | 5.5kw |

Hydraulic Power | 4kw |

Stand | 11-18 |

Control System | Mitsubishi PLC frequency conversion |

Hydraulic Cutting Material | Cr12 heat treatment |

Speed | 5-8m/min |

Decoiler | 5 tons manual or hydraulic |

NO. | Model | Width | Thickness | Cover Width(mm) | Host Size(L*W*H) | Power(kw) |

1 | 24-210-1025 | 1200 | 0.4-0.8 | 1025 | 7*1.6*1.3 | 4 |

2 | 28-207-1035 | 1200 | 0.4-0.8 | 1035 | 8*1.3*1.2 | 4 |

3 | 25-195-780 | 1000 | 0.3-0.8 | 780 | 8*1.3*1.2 | 4 |

4 | 35-253-760 | 914 | 0.3-0.6 | 760 | 7.5*1.3*1.2 | 5.5 |

5 | 28-220-1100 | 1250 | 0.3-0.6 | 1100 | 8*1.5*1.2 | 4 |

6 | 40-256-768 | 914 | 0.3-0.6 | 768 | 9*1.3*1.2 | 5.5 |

7 | 23-205-820 | 1000 | 0.4-0.8 | 820 | 8*1.5*1.3 | 5.5 |

8 | 30-190-950 | 1200 | 0.3-0.8 | 950 | 8.5*1.5*1.3 | 5.5 |

9 | 35-190-760 | 1000 | 0.4-0.8 | 760 | 9*1.5*1.3 | 5.5 |

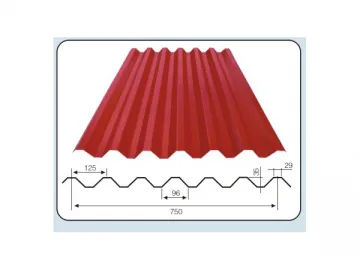

Yx30-190-950

Item | Description |

Material Width | 1200mm |

Material Thickness | 0.4mm-0.8mm |

Material | PPGI HDGI |

Yield Stress | 235Mpa |

Material of Roller | 45# steel plant hard chromium 0.05mm |

Diameter of Shaft | 80mm |

Voltage | AC380v/50hz or per customer’s requirement |

Motor Power | 5.5kw |

Hydraulic Power | 4kw |

Stand | 15 |

Host Dimension | 8.5*1.5*1.2m |

Control System | Mitsubishi PLC frequency conversion |

Hydraulic Cutting Material | Cr12 heat treatment |

Speed | 5-8m/min |

Decoiler | 5 tons manual or hydraulic |

YX28-220-1100

Item | Description |

Material Width | 1250mm |

Material Thickness | 0.4mm-0.8mm |

Material | PPGI HDGI |

Yield Stress | 235Mpa |

Material of Roller | 45# steel plant hard chromium 0.05mm |

Diameter of Shaft | 80mm |

Voltage | AC380v/50hz or per customer’s requirement |

Motor Power | 5.5kw |

Hydraulic Power | 4kw |

Stand | 13 |

Host Dimension | 7.8*1.5*1.2m |

Control System | Mitsubishi PLC frequency conversion |

Hydraulic Cutting Material | Cr12 heat treatment |

Speed | 5-8m/min |

Decoiler | 5 tons manual or hydraulic |

Yx28-207-828/1035

Item | Description |

Material Width | 1000/1200mm |

Material Thickness | 0.4mm-0.8mm |

Material | PPGI HDGI |

Yield Stress | 235Mpa |

Material of Roller | 45# steel plant hard chromium 0.05mm |

Diameter of Shaft | 80mm |

Voltage | AC380v/50hz or per customer’s requirement |

Motor Power | 5.5kw |

Hydraulic Power | 4kw |

Stand | 13 |

Host Dimension | 7.8*1.3*1.2m / 7.8*1.5*1.2 |

Control System | Mitsubishi PLC frequency conversion |

Hydraulic Cutting Material | Cr12 heat treatment |

Speed | 5-8m/min |

Decoiler | 5 tons manual or hydraulic |

Machine Placement and Operator

The tile forming machine should be placed on an even cement floor and lifted by a lifting device with a lifting capacity not less than five tons. It requires space for storing materials and laying the machine and room to operate the machine. In addition, the forming machine requires one operator and one porter. The temperature in the workspace should be no less than -14℃.

Established in 1996, Haide Machinery Manufacturing Company is an ISO9001 certified tile forming machine manufacturer and supplier based in China. In order to suit each customer's forming machine needs, we provide a wide array of forming equipment, including roof panel forming machines, sandwich panel production lines, corrugated sheet forming machines, and so on. Due to their high precision, high efficiency, easy operation and low maintenance cost, our roll forming equipment is sought after by customers in Chile, Bolivia, Thailand, Armenia, Uzbekistan, Cameroon, Russia, Saudi Arabia, Turkmenistan, etc.

If you would like more information on any of our products, please feel free to contact us. We look forward to working with you.

Links:https://globefindpro.com/products/110560.html

-

Welded

Wire Mesh Panel

Welded

Wire Mesh Panel

-

Barbed Wire

Barbed Wire

-

MPO Ribbon Patch Cable

MPO Ribbon Patch Cable

-

Galvanized Wire Netting

Galvanized Wire Netting

-

CNC Bender, Automatic

CNC Bender, Automatic

-

Welded

Wire Mesh

Welded

Wire Mesh

-

T10 LED Fluorescent Tube, YK-B1011J

T10 LED Fluorescent Tube, YK-B1011J

-

Laser Cutting Machine, 700-1500W

Laser Cutting Machine, 700-1500W

-

Roof Panel Forming Machine

Roof Panel Forming Machine

-

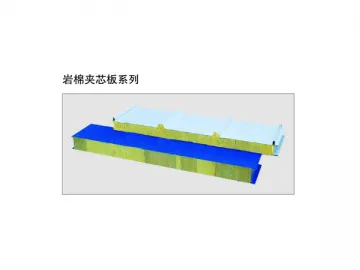

Sandwich Panel Production Line

Sandwich Panel Production Line

-

Die Board Laser Cutting Machine, 200-300W

Die Board Laser Cutting Machine, 200-300W

-

T10 LED Fluorescent Tube, YK-B1020J

T10 LED Fluorescent Tube, YK-B1020J